Matador

Well-known member

Spencerleehorton said:Hi Guys,

how do i get hold of a couple of pcbs for this?

Has anyone done a link to mouser yet for the BOM?

really interested in this.

regards

Spence.

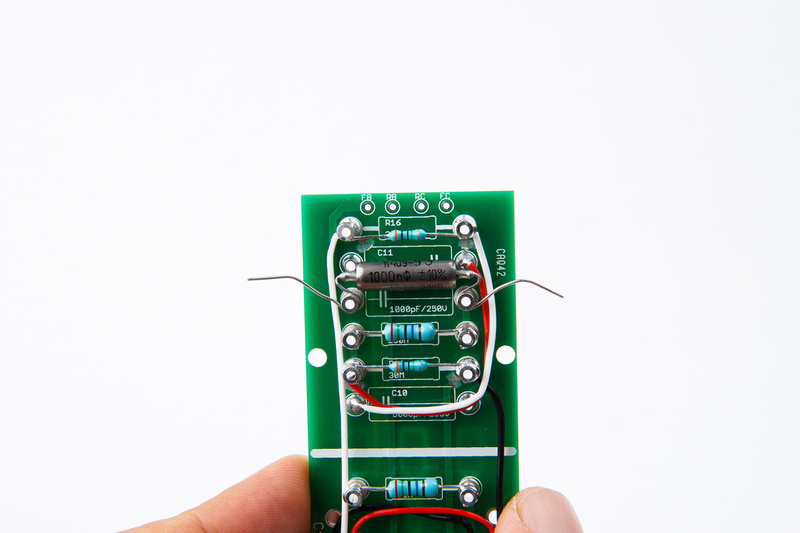

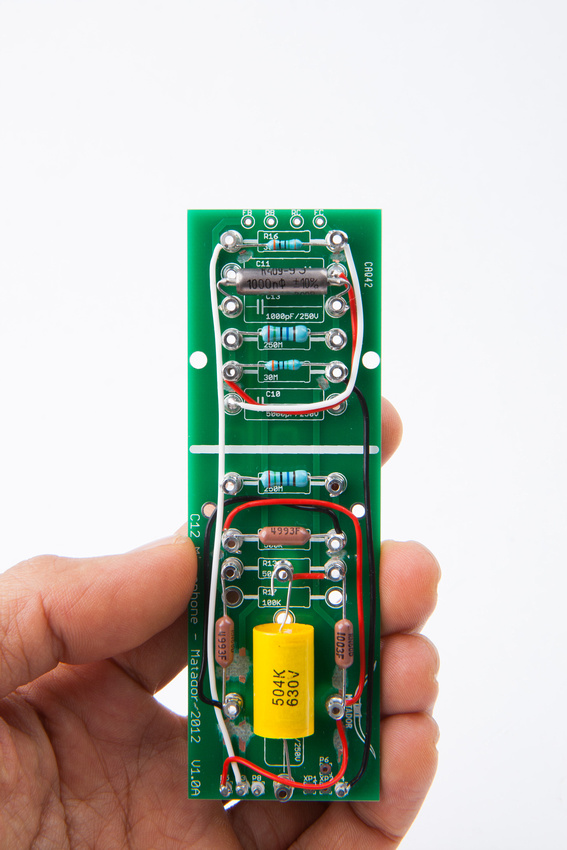

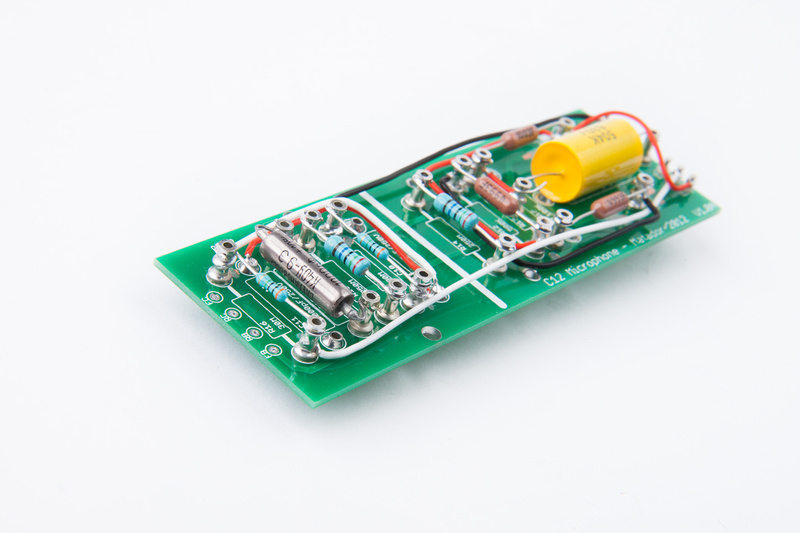

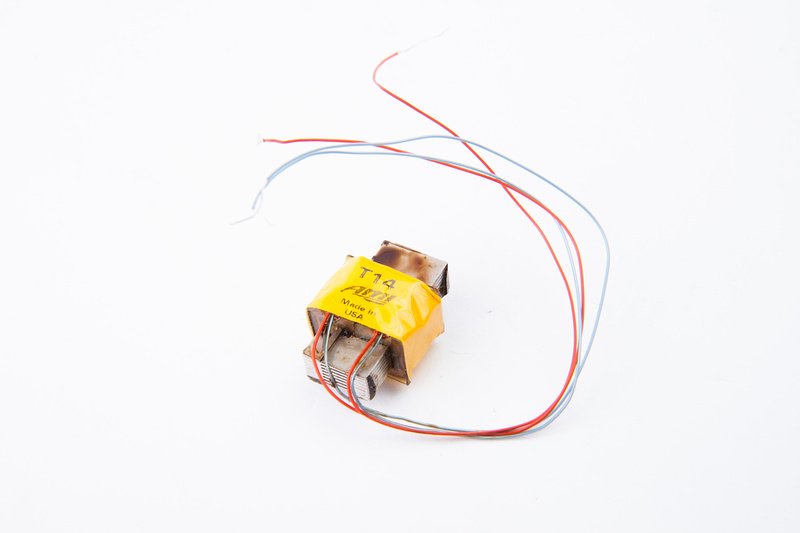

We are still prototyping a few BOM / capsule / transformer / layout combinations. I expect we should be ready for prime time very soon.

Of course, we still have 15 color combinations to try next!

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)