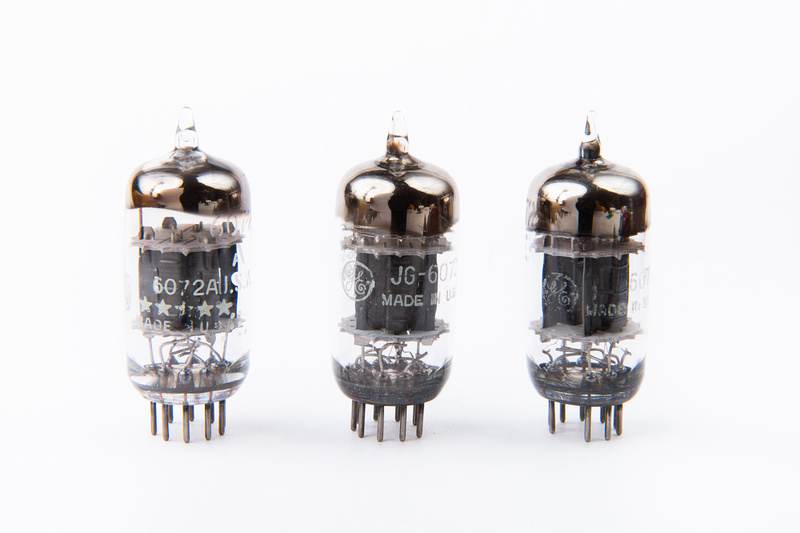

They exist still . . . in the wilds. GE 6072a mic-grade tubes ;D

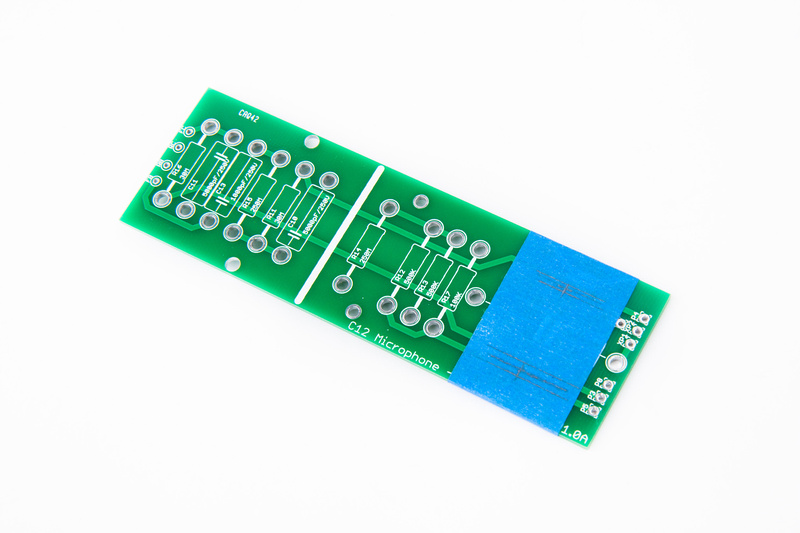

OK. . . I did say that I suck at prototyping because I lack diagnostic skills, but since we have the pcb's and I have some ideas in my head about component placement. . . here we go. I'll just go ahead and bite off more than I can chew again.

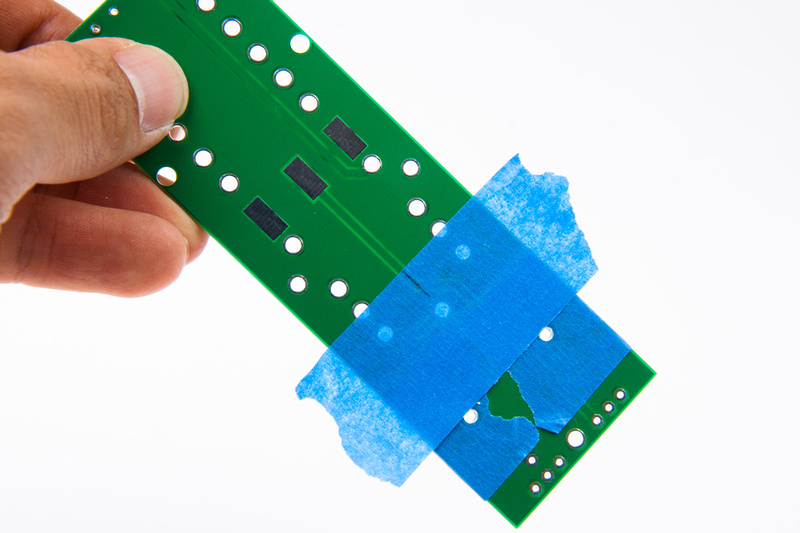

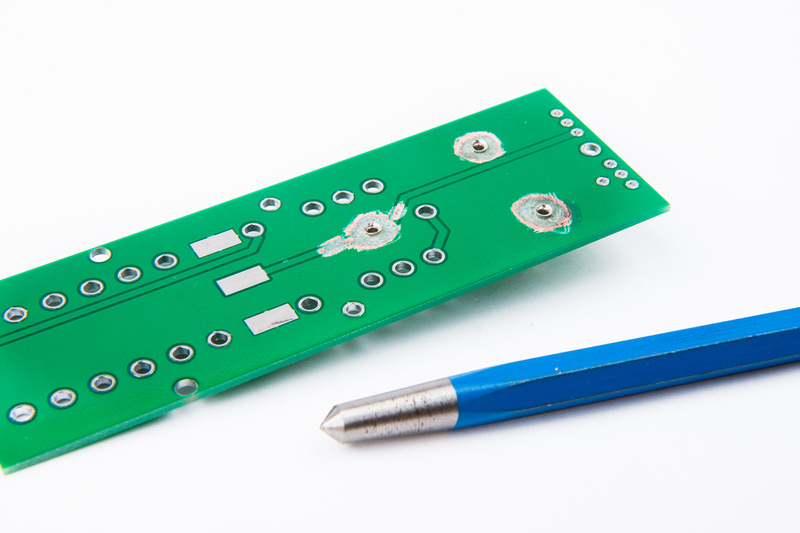

Marking the location of some new holes I need.

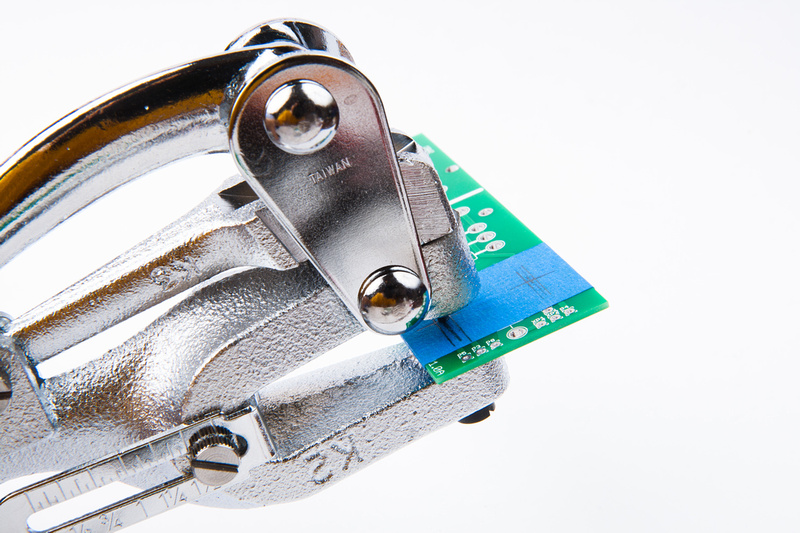

And, let's just get right to hacking up a perfectly good pcb. This is a hole punch I bought to do my turret board version of ioaudio's mk47 psu.

Doesn't work half bad on a normal pcb.

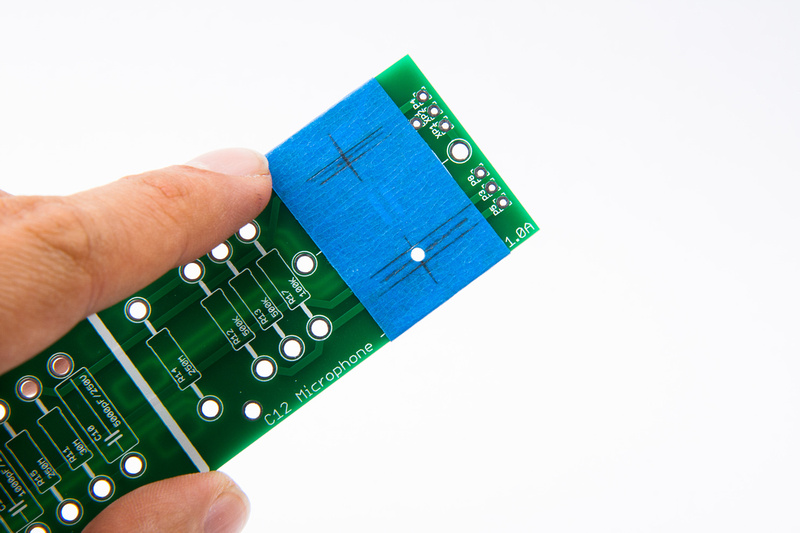

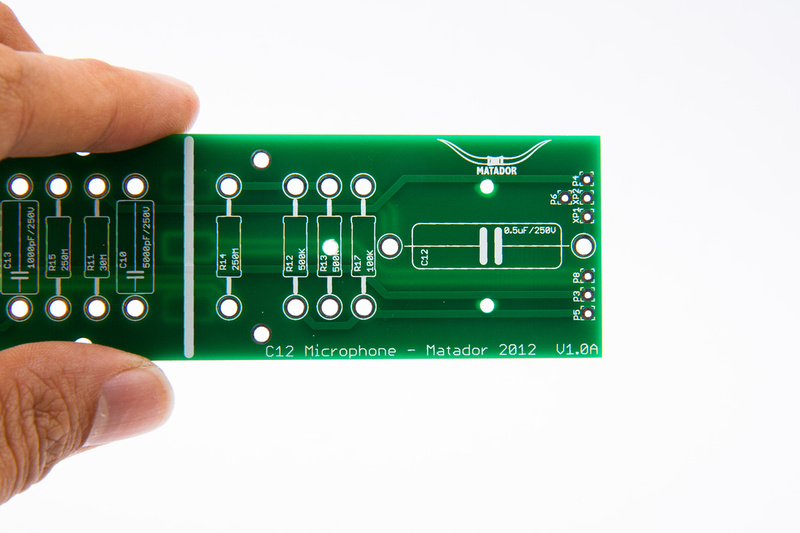

Marking my location for my 3rd "extra" hole.

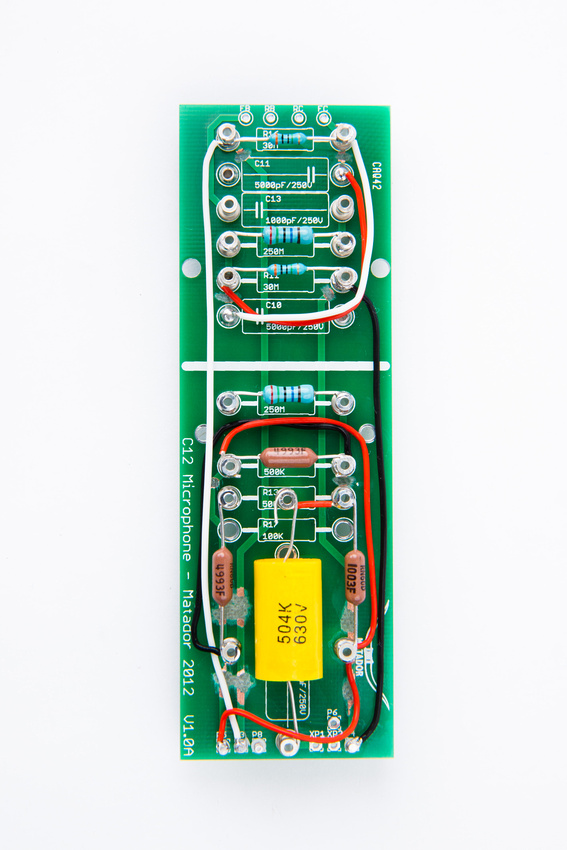

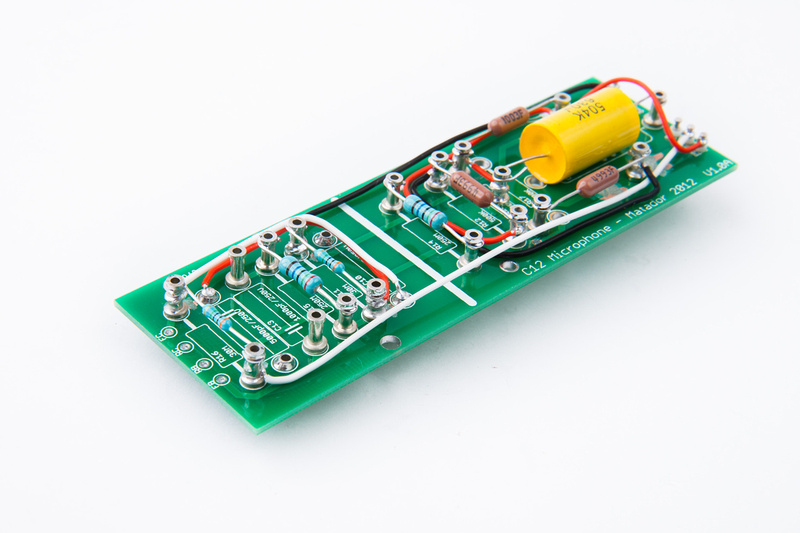

And new holes are in. . . What I'm trying to do is make a little more room length-wise for C12 by making R13 and R17 longitudinally oriented instead of perpendicular.

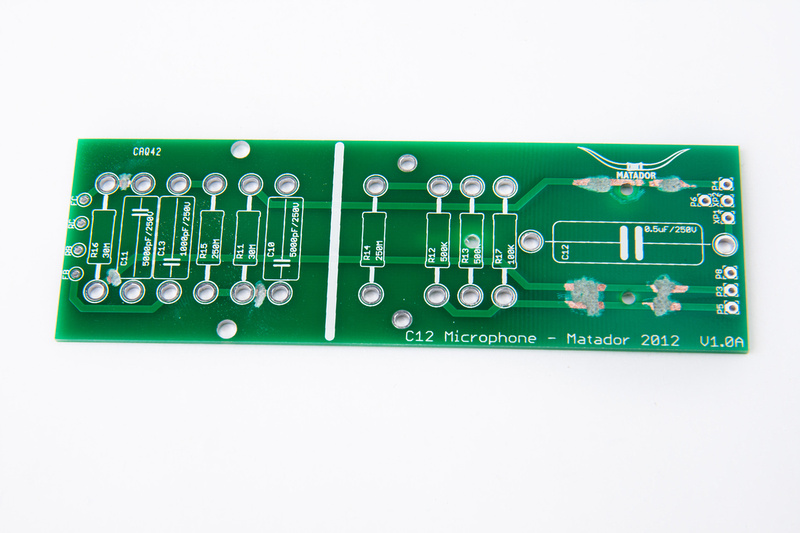

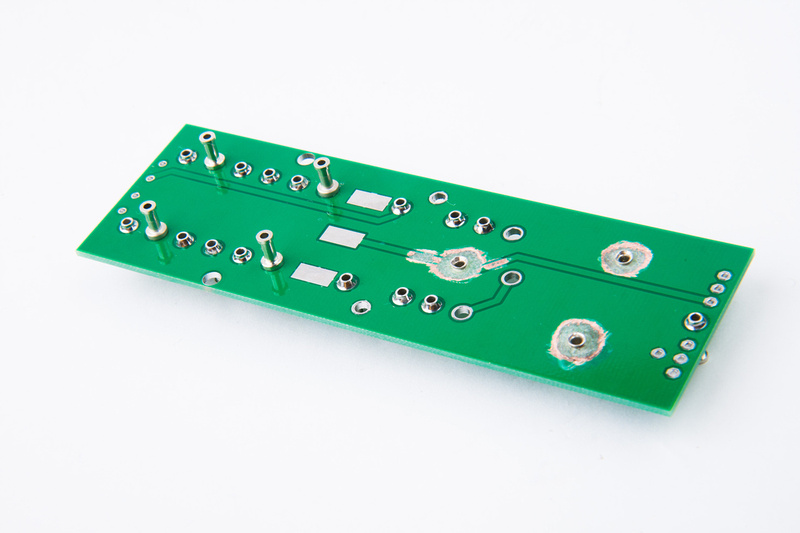

And some trace grinding.

And some more trace grinding and groundplane grinding on the back side.

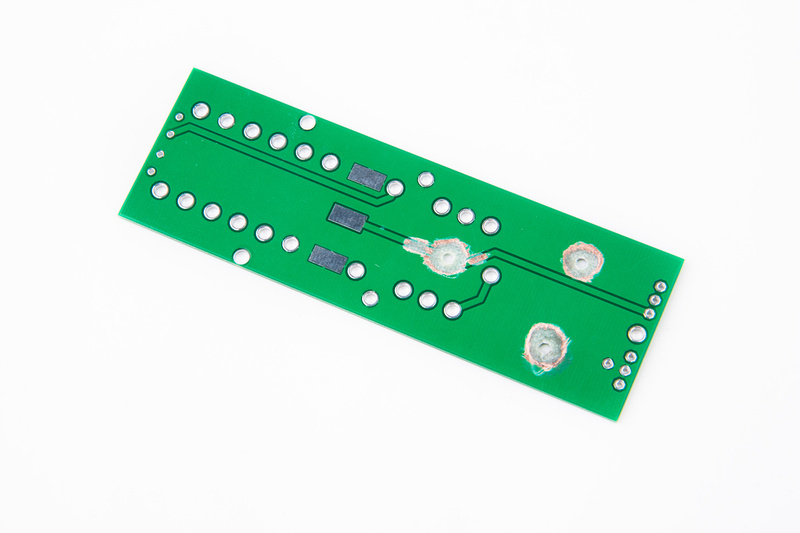

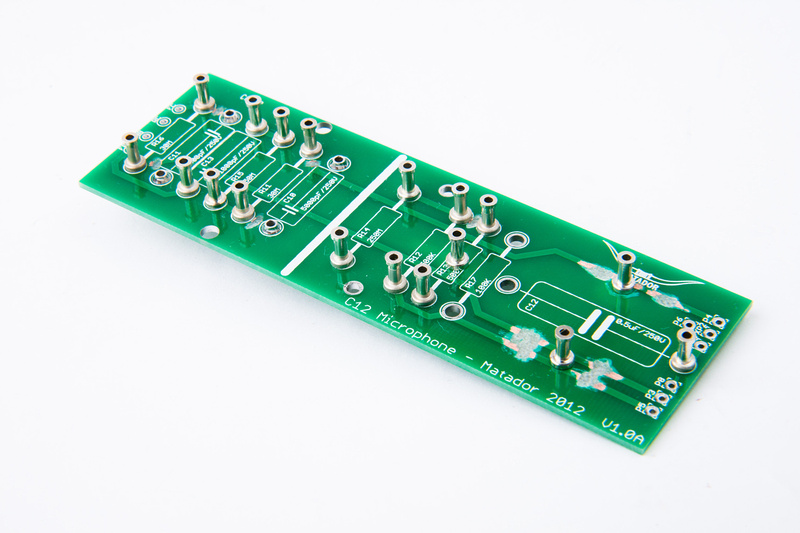

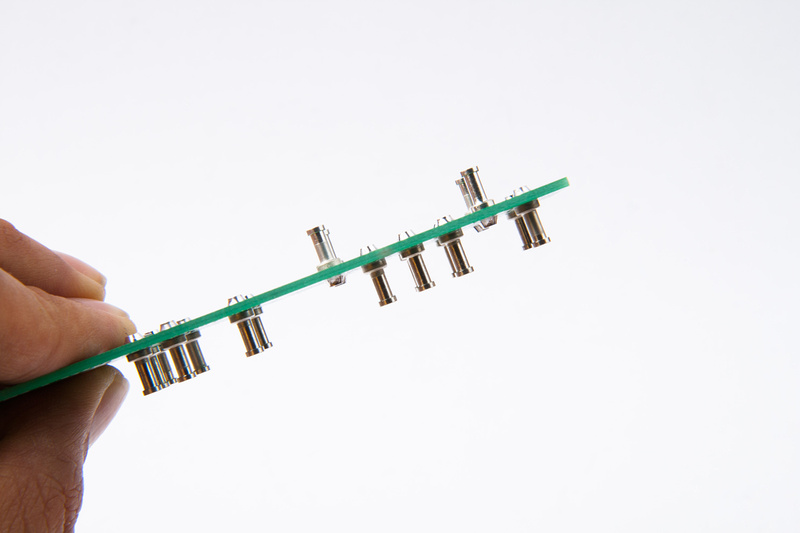

New turrets go in. . . the holes are optimized for press fitting so they work pretty well, but this pcb is much thinner than 1/8" G10 board.

So, I decide to swage the ends with a center punch because that's the only tool I had on hand.

Next, I solder in the turrets I will be utilizing on the pcb.

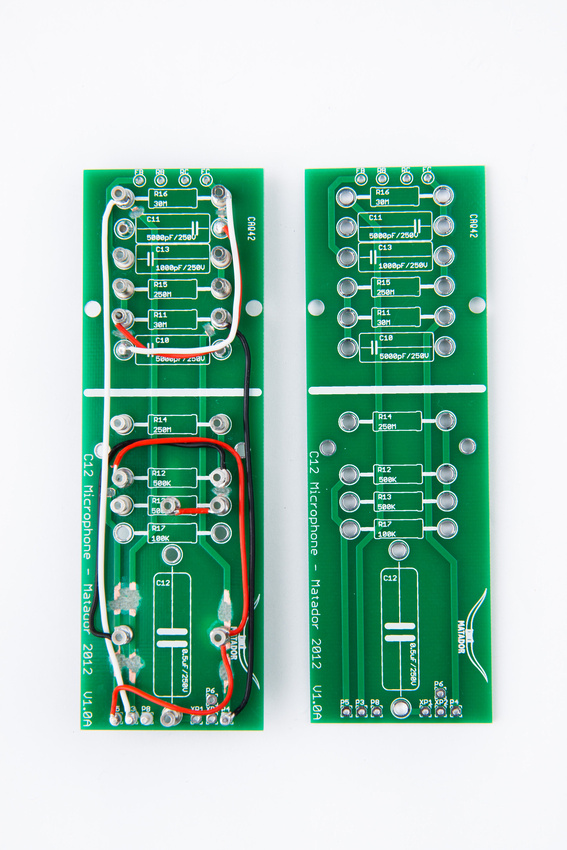

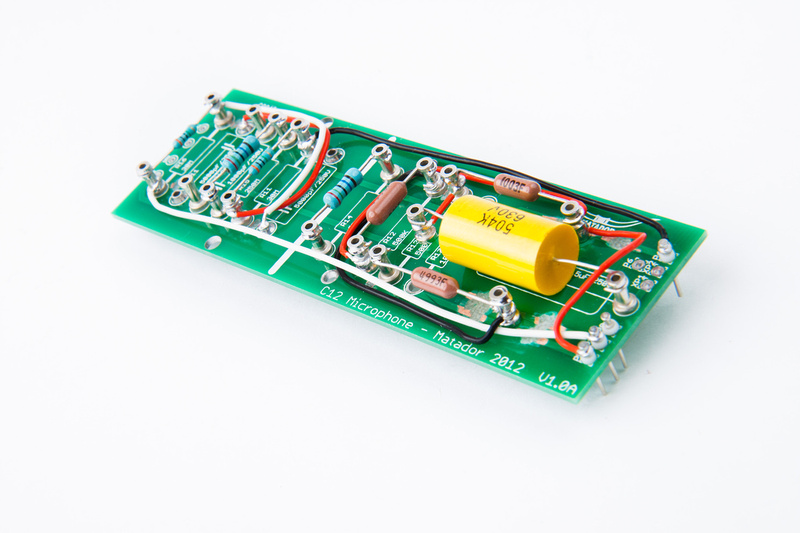

I'm also making a change on the top side of the mic in order to facilitate Russian PIO caps in the C10, C11, and C13 positions. I'm moving C11 and C10 to the back side of the pcb and mounting them longitudinally to gain more length and width. C13 will then have a bit more space because the space C11 used to occupy (right above it) has been vacated.

My suggestion to Matador was to leave out the traces on these C11 and C10 to give the option of building in either orientation. A few leads will have to be manually configured, but the build is very conducive to that. But, knowing him, he'll come up with some awesome new configuration that would allow for both options natively.

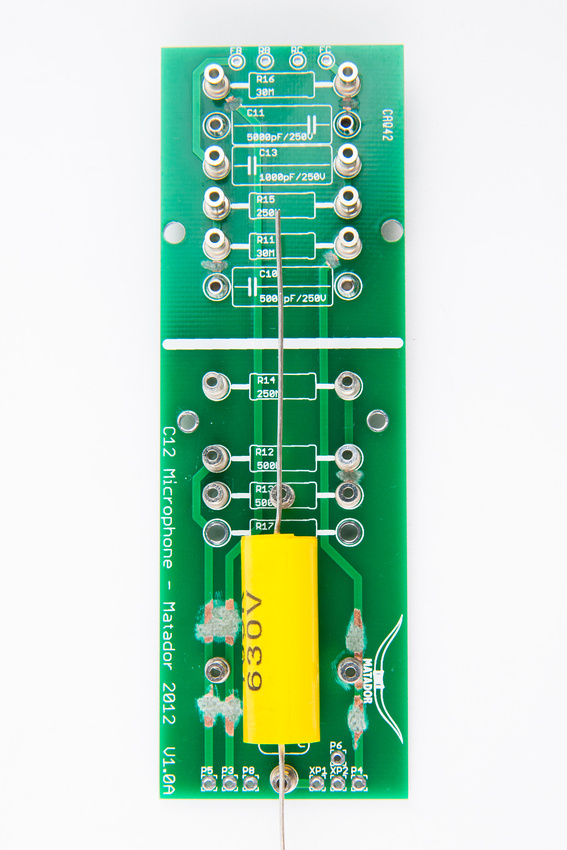

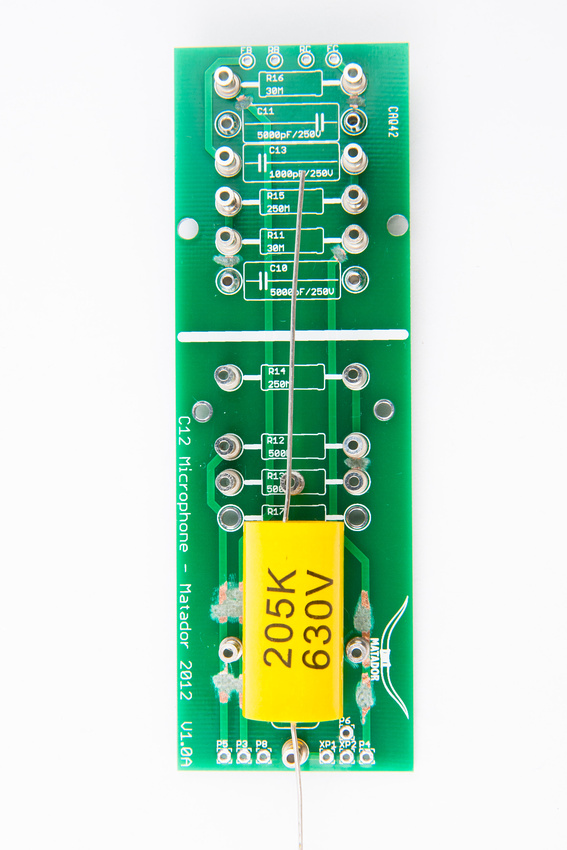

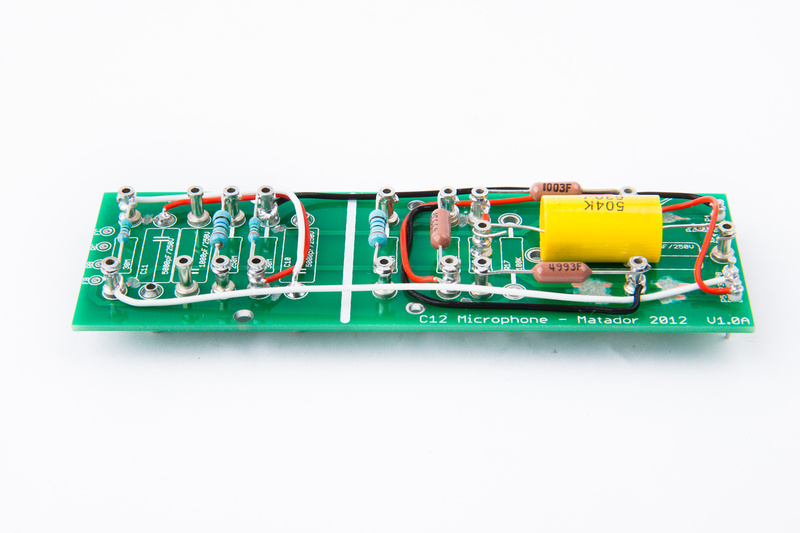

On the bottom side of the pcb, the main reason I'm trying to get a little more length on C12 is the 1uF capacitor that is commonly used in this microphone. . . this version was just barely too long for the v1.0 pcb and it really doesn't hurt to give some options on this cap.

With my revised configuration, even moving up to 2uF 630V is ok. R13 and R17 will ride along side. You may also notice in the pic some more trace cutting has occurred. I think I'm really setting myself up for failure here on this 2nd prototype

.

The look and function of the layout Matador came up with is pretty awesome. . . with everything lined up and spaced evenly perpendicular to the pcb. I REALLY like it a lot and don't want to mess it up. But the tube of the mic is just not wide enough to allow for the PIO's in that configuration. Hopefully, this will be one way to retain the broad strokes of the nice look but open up a few more options.