JessJackson

Well-known member

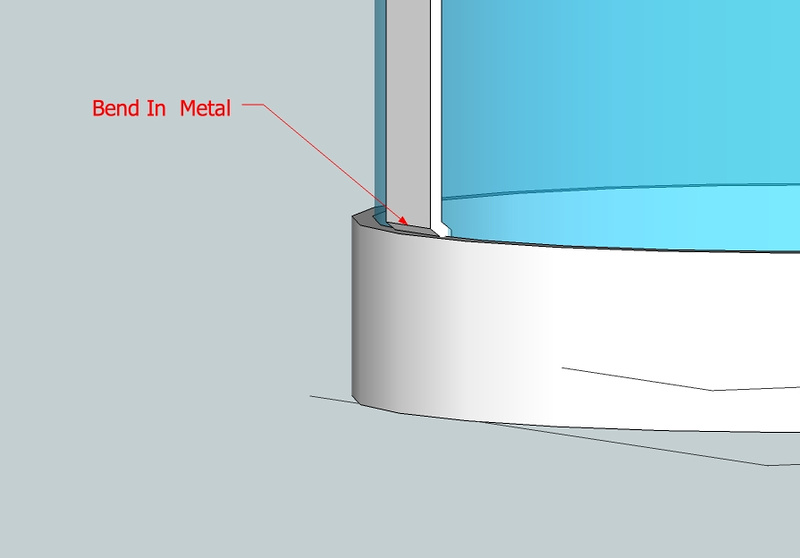

Nice but They need to solder the vertical mesh supports (left and right) to the edge of the base not to the inside. This at the moment aesthetically doesn't look good in my opinion. The lines on a c12 should be fluid from top to bottom.

chunger said:OK. . . the good news from the Motherland is we have headbasket prototypes!!! These are officially not vaporware anymore. The bad news is the tooling cost was about 2.5x the original quoted priceWell, done is done. From the pictures the factory provided, this looks on target. I will need to get hands-on to confirm.

Here is the single layer C12 variant

And the 2 layer Ela M251 variant

If there is a complaint on my end, it would seem the headbasket feels a little bit on the high side. I did tweak the dimensions a few iterations before settling in on the final sizing so I need to confirm that the factory used my latest revision drawing to generate their tooling, but it does appear to be correct to my specification. Because the HT-11A body tube is wider and shorter than the original C12 tube, it's a compromise fudging the headbasket proportions. From the pictures that I squinted at continuously while doing the design, it seemed the C12 placed the capsule low in the headbasket which is why I favored taller on the headbasket in the end.

For the 2 layer Ela M251 configuration, it seems my meshing at least on the outermost layer may need to be tighter than the current 12x12 material.

CAn someone confirm 14x14 .020" diameter outer layer mesh configuration for the Ela M251? I think that's where this is headed. Also, I have no clue as to the inner mesh specification. Internet data to date is chirping birds.