I probably measured something off and it all went horribly wrong ;D

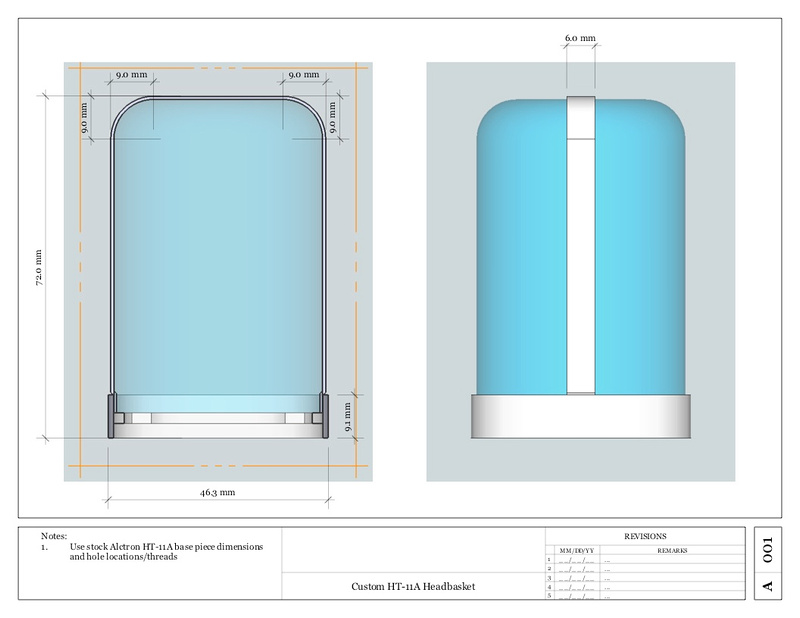

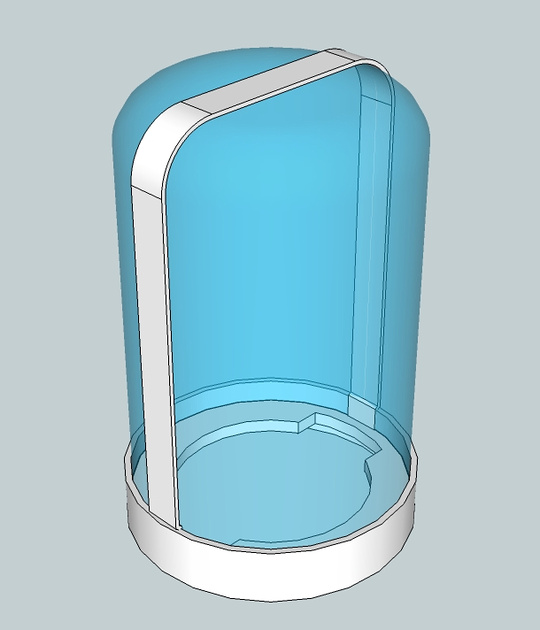

I did make a bit of progress on the headbasket.

I also found a factory to make them for me at a very reasonable price. . . trouble is, I'll have to order 500 on the 1st go because of tooling. Well, that just means I'll have quite enough to go around. I may also try to contact a few small-scale manufacturers that use the HT-11A pattern microphone for their retail products to see if they may be interested in taking a few of these off my hands once I get them.

The Apex 460 is wider than C12 and narrower than ELA M251 which makes it an interesting exercise making a headbasket for either one. Since we are planning to do ELA M251 project next, I figure I will make the order with double layer and single layer mesh. Also, to complicate things more, there were at least 2 versions of the C12 headbasket one being taller than the other. That being the case, the best I can do with the HT-11A platform is to proportionally fudge everything a bit and make the hoop configuration closer. Beyond that, if you require exact dimensional match to the original C12, flea or AMI would be the path to take or home-brew the tube.

As for the mesh material, as near as I can figure, it is about 10.5 squares per inch on quite a few C12 images. This is visually determined based on 34mm capsule diameter in pictures. I have not found someone yet to put a ruler to an actual C12 for me although that would be a simple exercise. 10x10 brass mesh with a 10% tolerance and .025" width wire is probably the closest readily available material. I wouldn't be surprised if the forming process compresses the mesh a hair yielding 10.5 squares per inch upon final assembly.

I am still trying to determine the inner mesh spec for the ELA M251. Another problem I'm thinking of in the back of my mind is an indication by Tim Campbell or was it Gyraf on this board mentioning that grid opening of greater than 1.5mm allows for RF and other interference. . . the 10x10 mesh is about 1.7mm but any way I measure it, I don't see the original grid being 12x12 mesh which is the next step tighter. Due to the cost of the capsule, I may very well run dual layer grid material on my personal mic assuming the sonics in that configuration are solid. Excellent noise rejection and protection for the capsule are important to me. But, we won't know anything concrete until we get some test/production samples. I have sent one HT-11A to the factory that will be producing the headbasket so we can make sure everything fits perfectly before they ship samples out and they get the mating surfaces and holes correct. Once samples are in, I will be able to test the 2 grid setups. I'm hoping these will be low enough cost that people can experiment with it just like a cap, resistor, or other tweakable mic parameter.

UPDATE: My internet-fu is working again. . . it appears the mesh may in fact be 12x12 and the part right over the front of the capsule is in the "stretched" portion of the material yielding the strange 10.5 per inch measurement. I think I will try 12x12 .025" mesh first at least on the sample.