Turbo is already inside.for me on gssl without turbo and without dbx 202 it's not like the real console or gfx 384

Well, let's do provision for 202's...

Also don't know if he was planning on incorporating all of the features that I was.

I think, even more.

Like always.All boards will be components on top side, double sided copper with plated thru holes, values and Reference designators silkscreened on board.

Yep, this is hard to design dualsided board with wirej umpersJumper wires eliminated

Yep.Off-board (slightly redesigned) Power supply with incorporated bridging and rail filtering

Yep.Smaller main board (50% - 75%) smaller than current design.

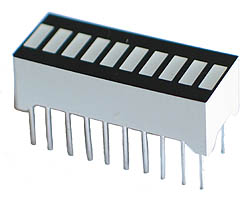

And 202's, if there will be 10 votes on this threadDesigned for use with THAT2180/2181 VCA's.

http://www.groupdiy.com/index.php?topic=38924.0

yepSecond sidechain incorporated directly onto main board

yep(with connector provisions to bypass)

I can't find high cost resistors on GSSL. Strange. AnywaySome resistor value modifications allowing for standard 1% metal film values, eliminating any higher cost resistors

Nope, they're on power supplySpace allocated for using on board heatsinks on +/-15V Regulators

Nope, 500-series edge connector and simple XLR wiringPCB mounted XLR connectors (although they can still be hard wired also if chosen)

Yep. IMHO I was one of first forum people who started to use hardware bypass at every possible placesDirect audio bypass using relays

Yep, possible as well. I don't think there needed more than 2 bypass relays though.Relay and wiring provisions for using 2-3 Illuminated Pushbuttons

It possible to do even simpler, without affecting sterility of main power supplyRelays on dedicated additional 5V power supply

IMHO, HPF and Thr@st are the shoss...wellI was not planning on doing a HPF although I was planning on having connector provisions for easily connecting existing HPF boards.

AhaReadily available Loren Switches - orientations on control board adjusted so d slot are in correct orientation with selected switches

I don't want to spend tons of time on this if nobody will use it, but if it is of interest I will gladly move forward with it.

After making this one:

http://www.groupdiy.com/index.php?topic=24404.0

it took me about 150 hrs in total to re-lay everything into 500 format, mind,

schematics and board were already drawn, checked and tested.

Sounds cool. No, I never share Gerbers. Well, if you like to do this....Design/schematic/gerbers/BOM will be posted here on the forum and available to all of course

Interestingly, your thread poped up right after mine.

Is this same mind at the same time or...well...dunno.

I assume you did not started the design, if you finished the board and want

to share for free the gerbers, I'd stay with my 500 design