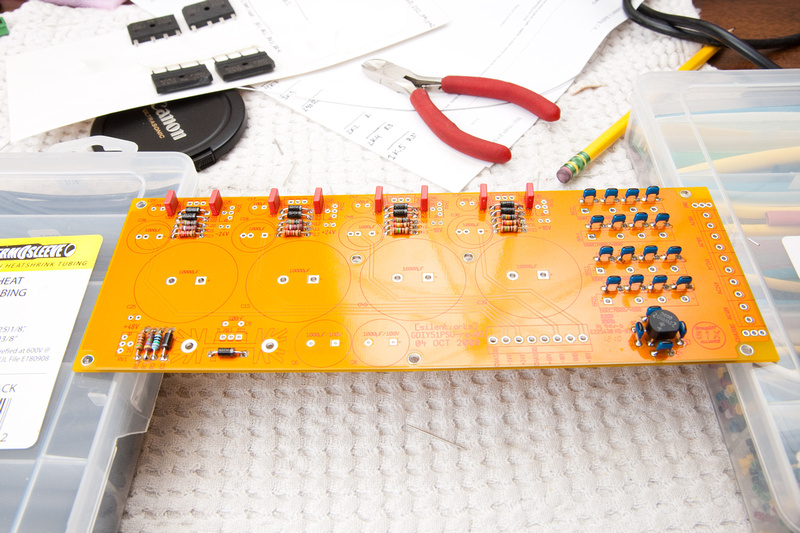

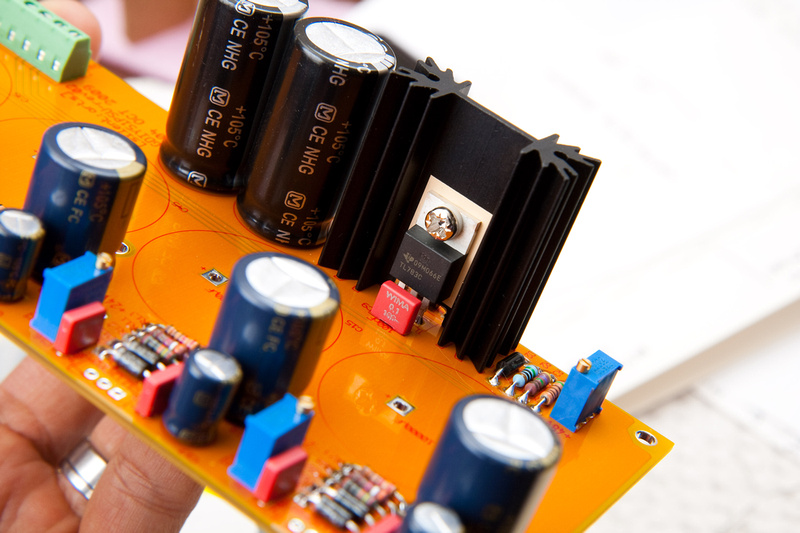

For the DC side, again, I took a look to see if I could identify the most difficult solder joints and start from there while I have access.

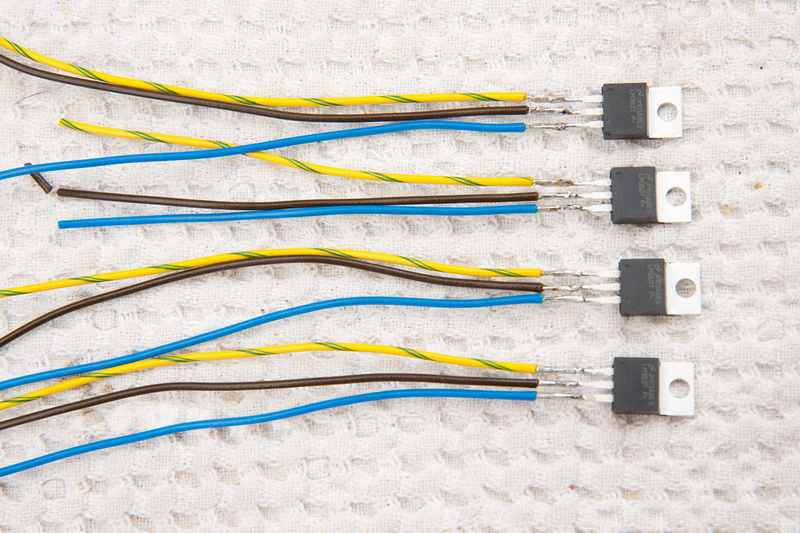

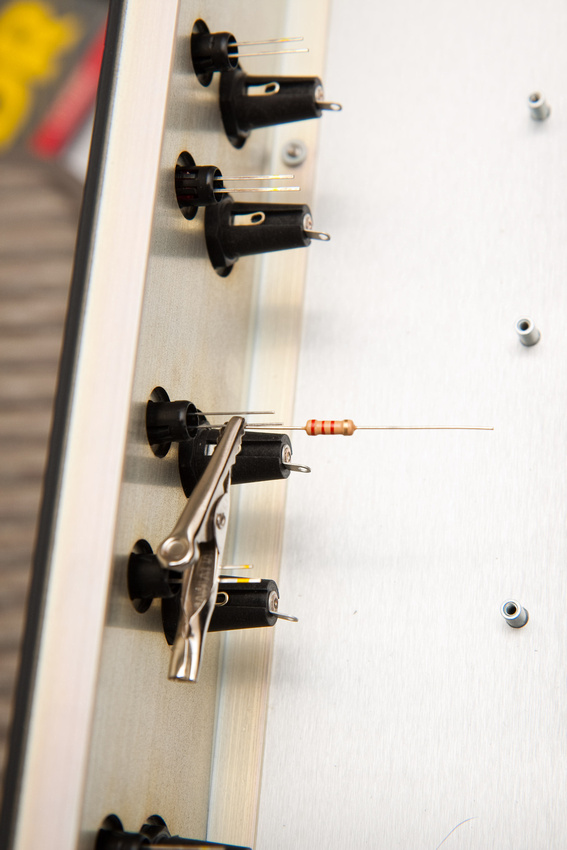

I went with attaching resistors to the LED leads first. After thinking about it for a little while, this is the method I came up with. I'm sure there are hundreds of correct ways to do it. Note, I tried testing the LED polarities first by connecting directly to the +16v and ground from the PCB, and the result was a very bright LED for a second, and then a very dead LED. Newbie me didn't know that you had to have the proper resistor in place. Luckily, I had a spare LED, so I threw that in without problem.

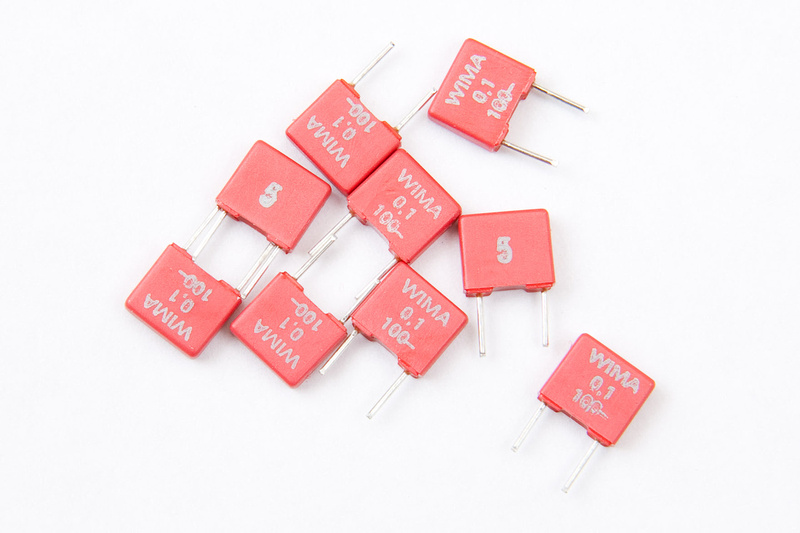

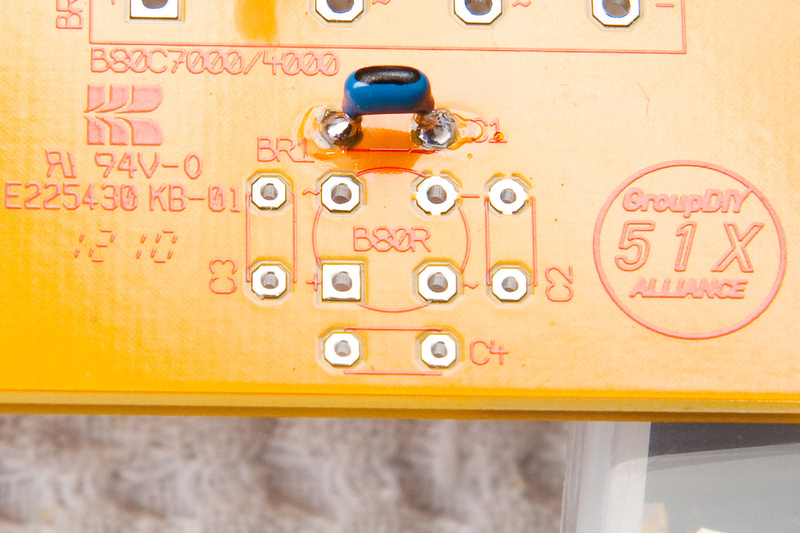

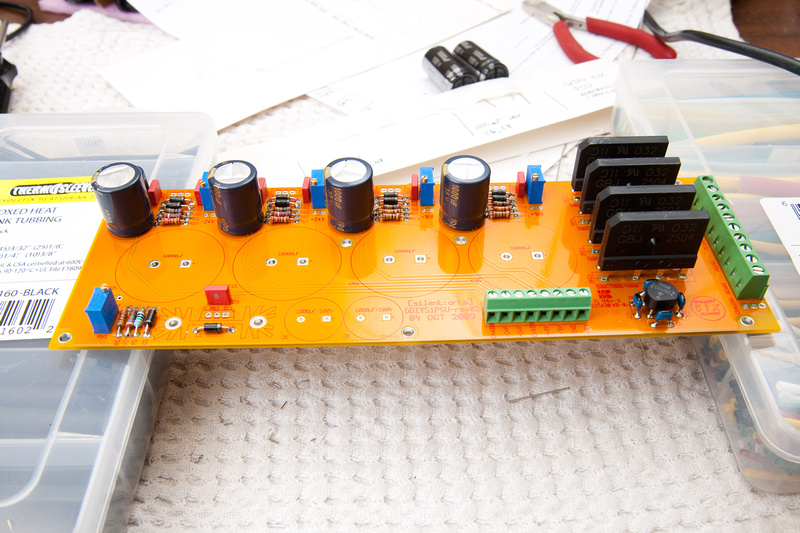

Note on LED resistors. . . in order to not buy extra resistors, the 5 resistors used for the LED's should not be populated on the PCB, but used on the the external LED's. Because I had very little understanding of the PCB when assembling, I just fully populated it. So, because I had ptownkid's kit on hand that I was not going to use in a PSU build, I used the resistors for the external LED's, and also installed the provided LED's internally on the PCB, so I could have shiny green lights inside ;D.

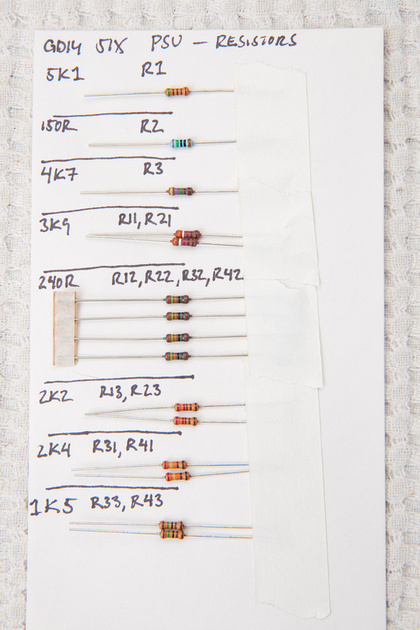

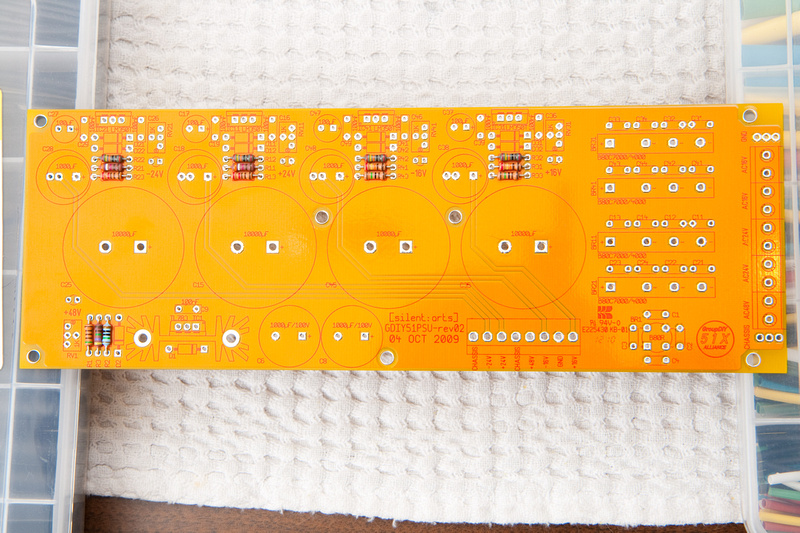

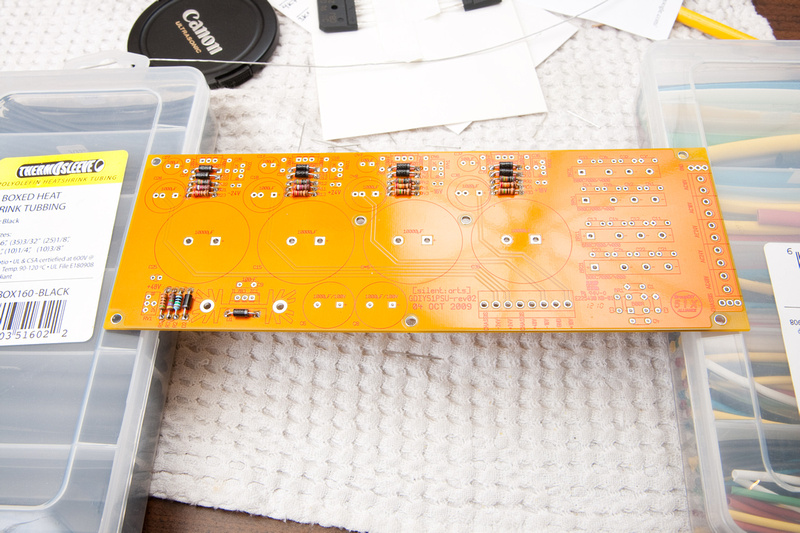

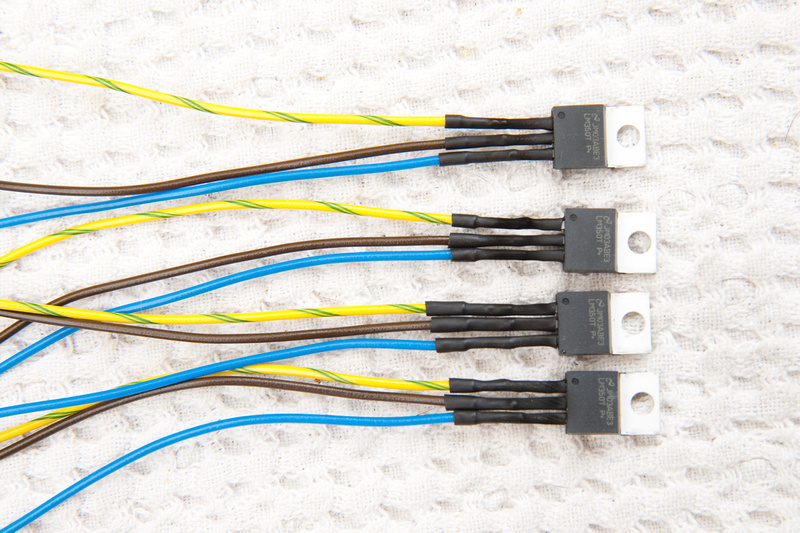

And, resistors are in:

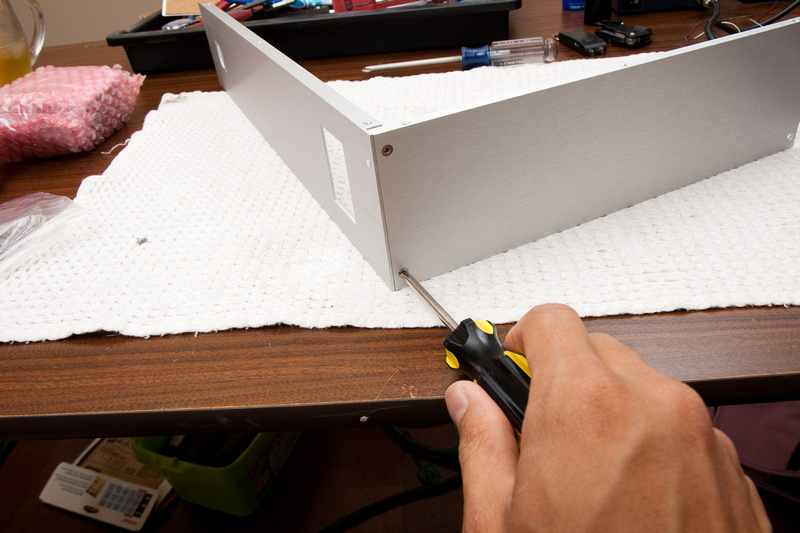

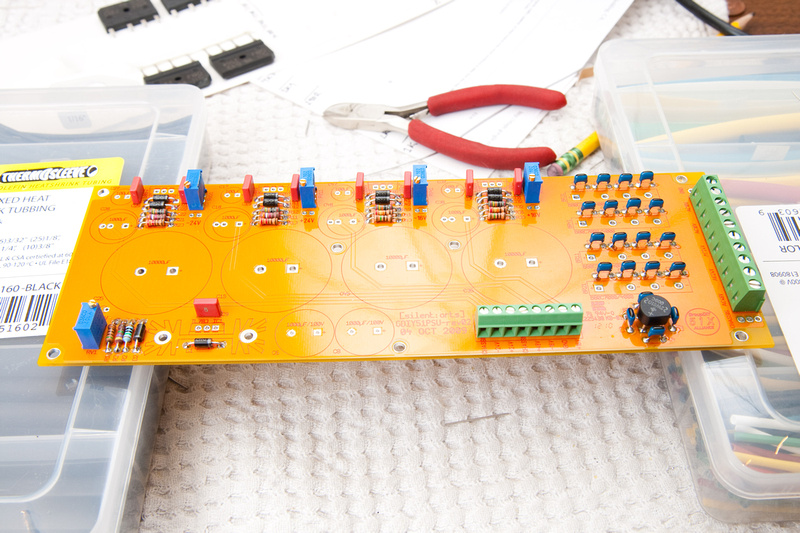

Next I went after the ground connections on the indicator LED's, and the methodology is similar. I found that the solder does not stick to the alligator clamp.

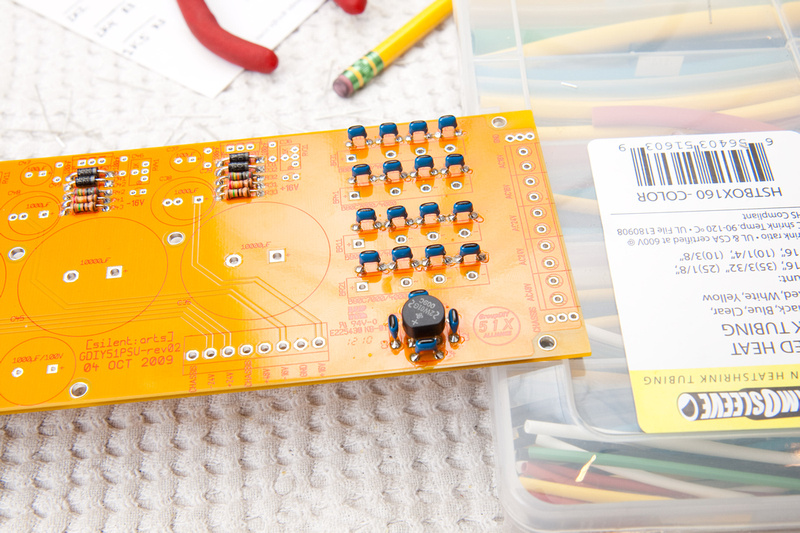

And, ground leads are in. . .

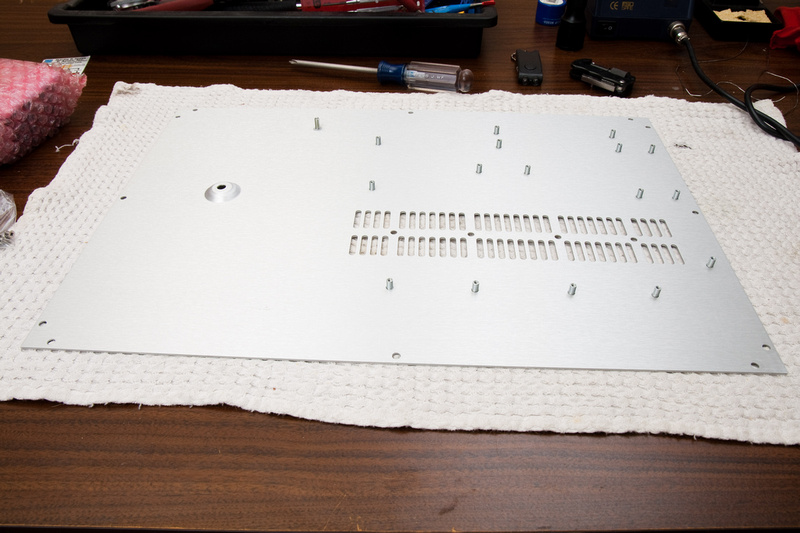

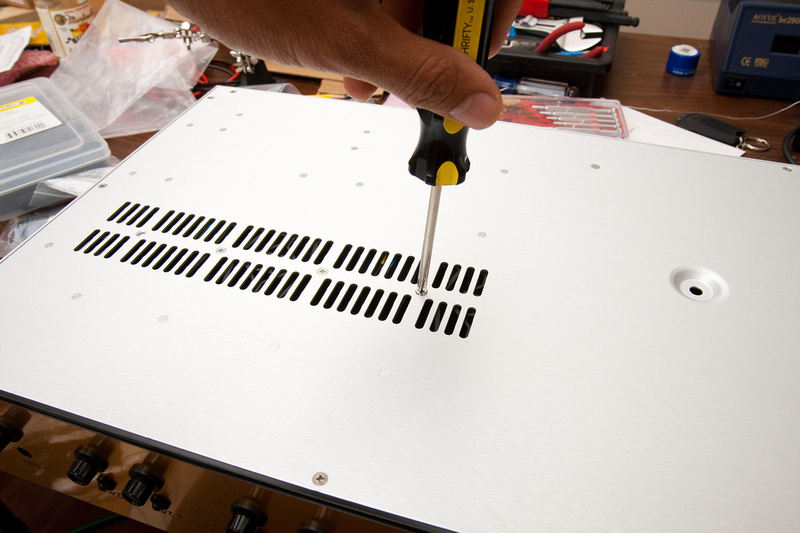

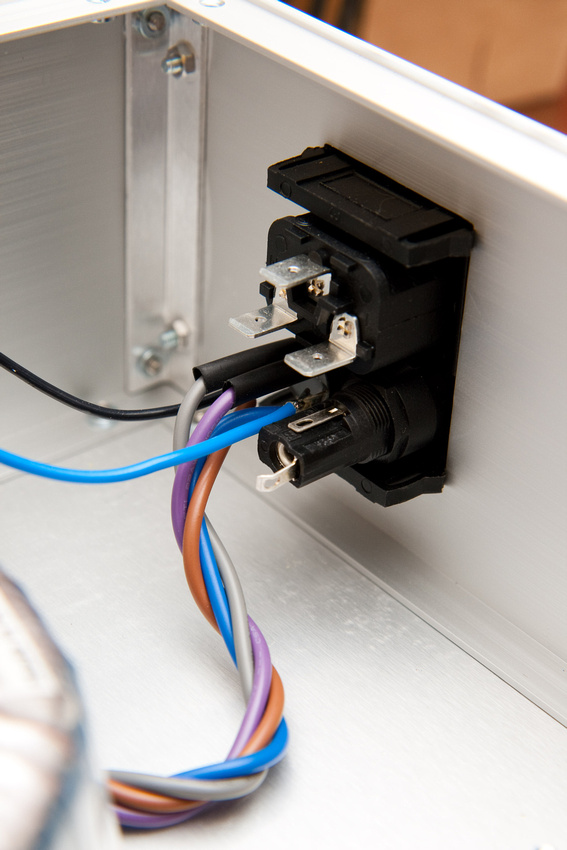

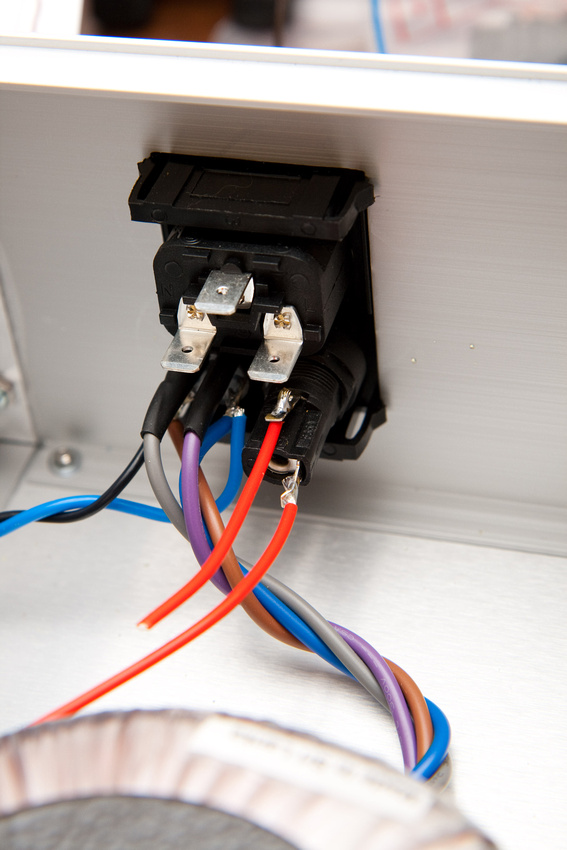

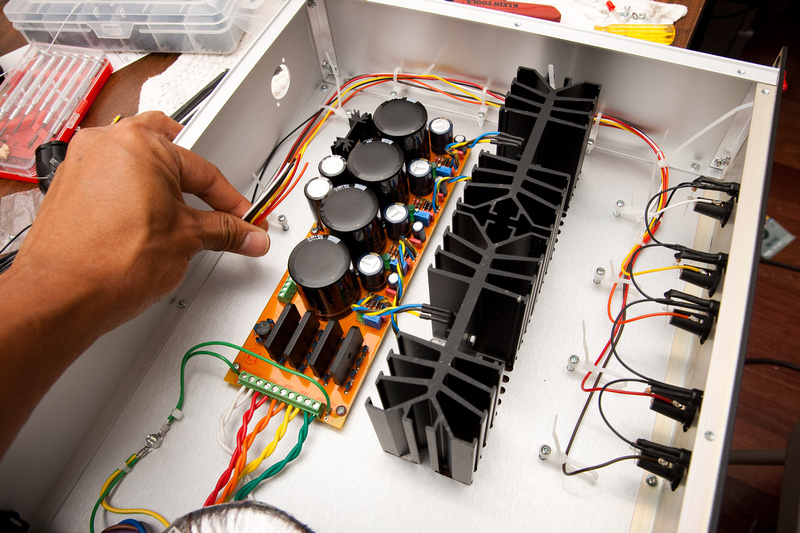

Next, I installed the cable control ties loosely and soldered in the input side of the fuses. . . and threaded the wires through towards the PCB DC outputs. I used some additional cable ties to clean up the run starting from the fuse side and working my way to the PCB side. I then cut off my excess cable with a bit of slack to spare at the PCB side.

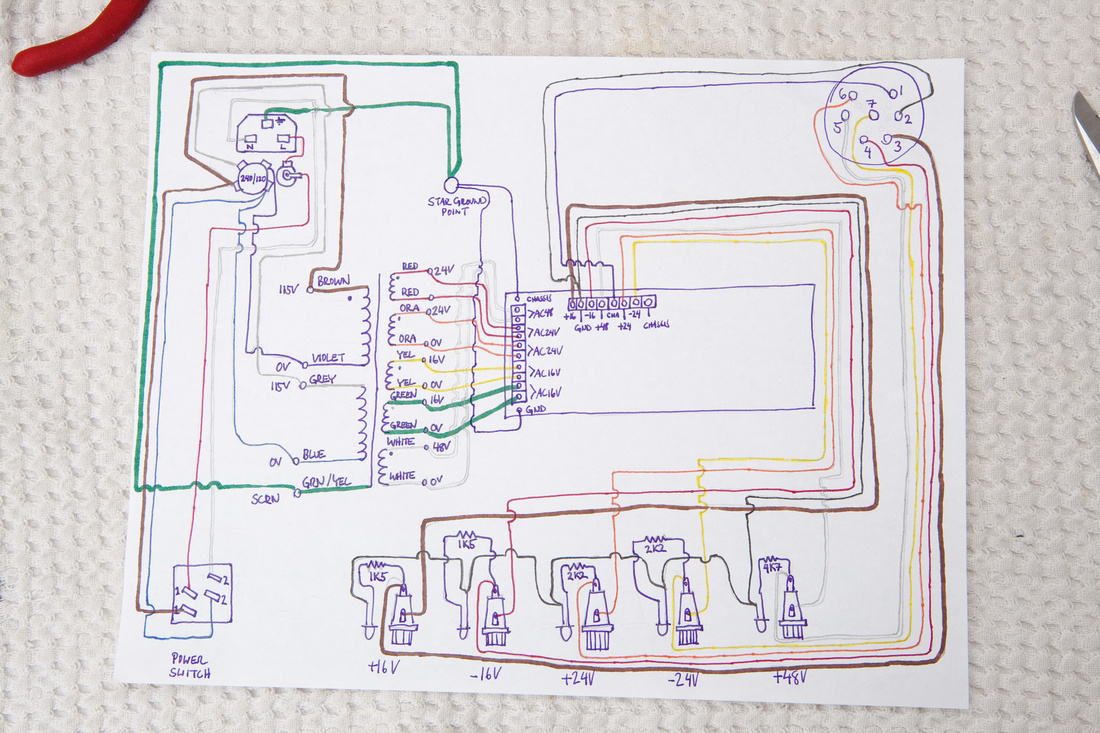

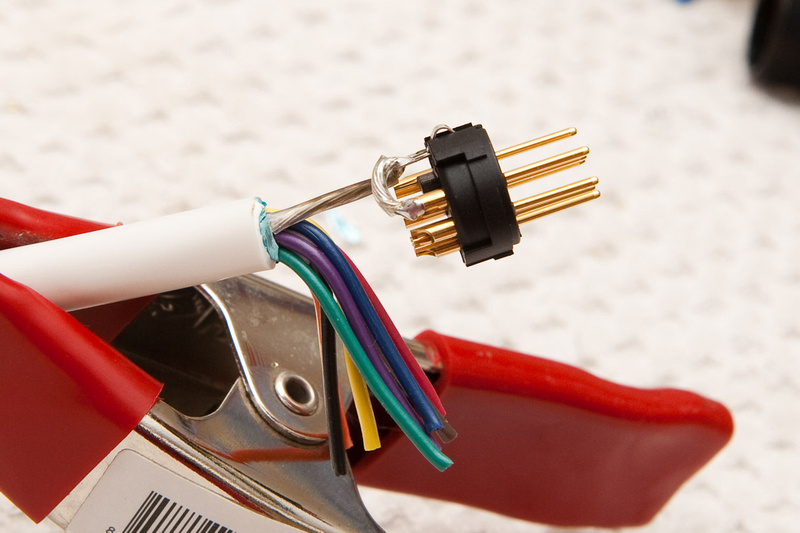

Again, referring to my map, I soldered my 7 pin Neutrik connector with the other half of the kit-provided wires that I just cut at the PCB side of the run.

After evening out the cables and roughly cutting my excess off, I taped the cable ends together with the exception of the ground an chassis lead (go directly to the PCB lugs). I then threaded the cable bundle through the rear cutout, through the cable ties towards the fuse side.

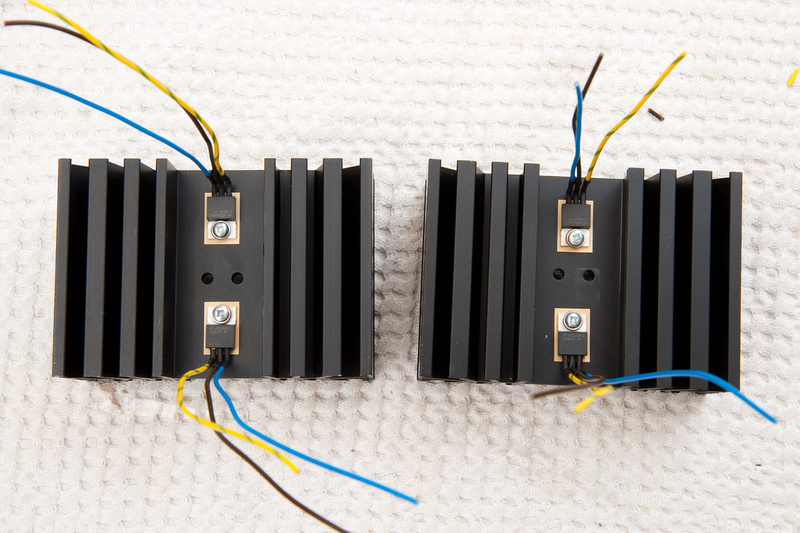

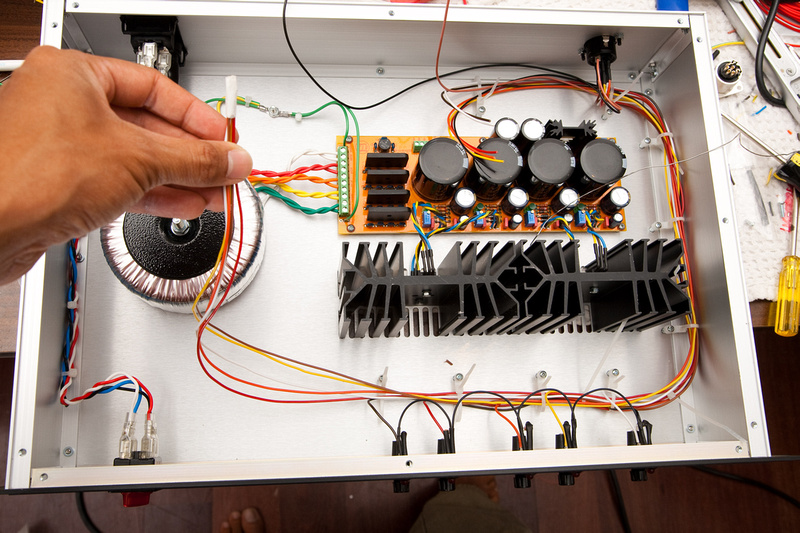

Next, I tidied up the cables and tightened down the cable ties from the neutrik connector toward the fuse side.. . then, I carefully cut and soldered the fuse output leads which also happen to connect to my LED resistors.

After this, all that's really left is to cut the leads at the PCB side, strip and tin the leads, and connect as per the map. Note, I left a bit of slack at the Neutrik connector which made he whole internal layout not as pretty as it could have been, but knowing me, I will find a way to need to take that connector out someday, and it would be a pain trying to solder, de-solder, or otherwise tinker with that Neutrik connector after it's in the chassis without enough slack to pull it out.

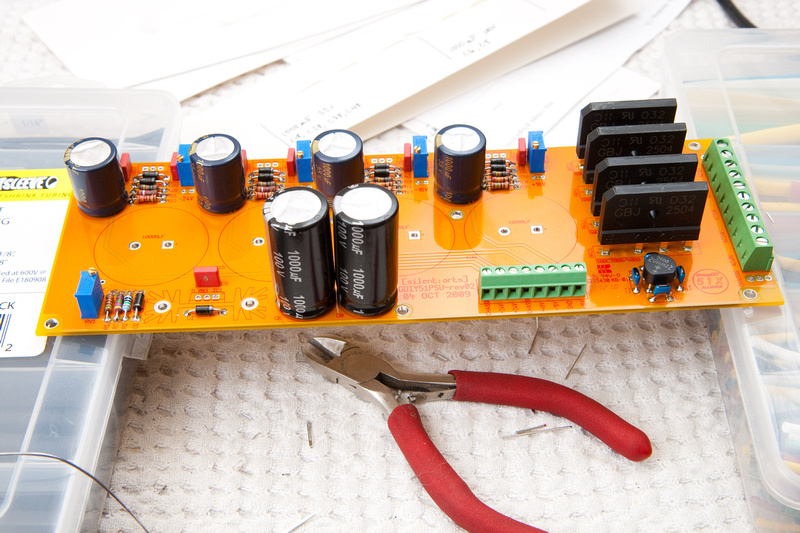

I insert the proper fuses. . . 1.6 amp for + - 16v, and + - 24v. 125mAh for 48v.

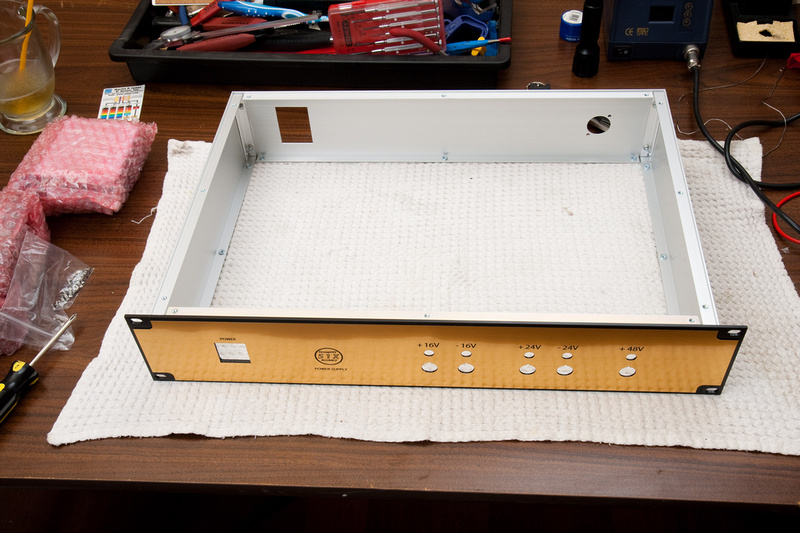

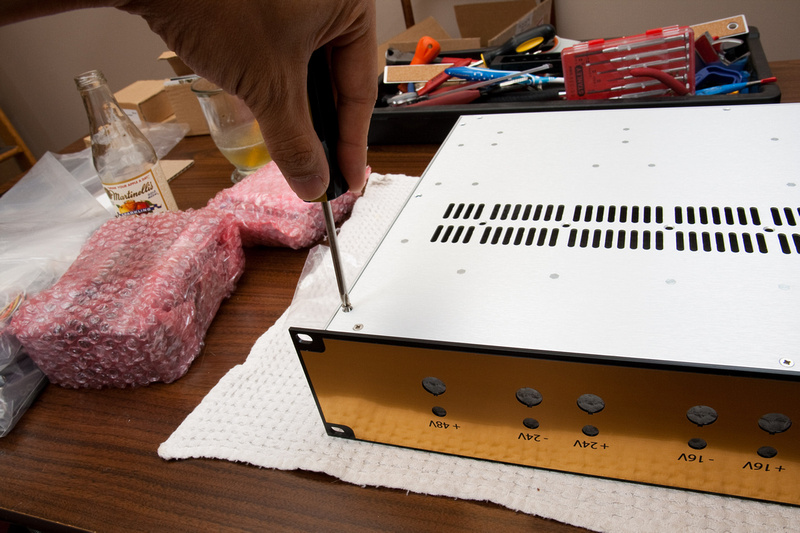

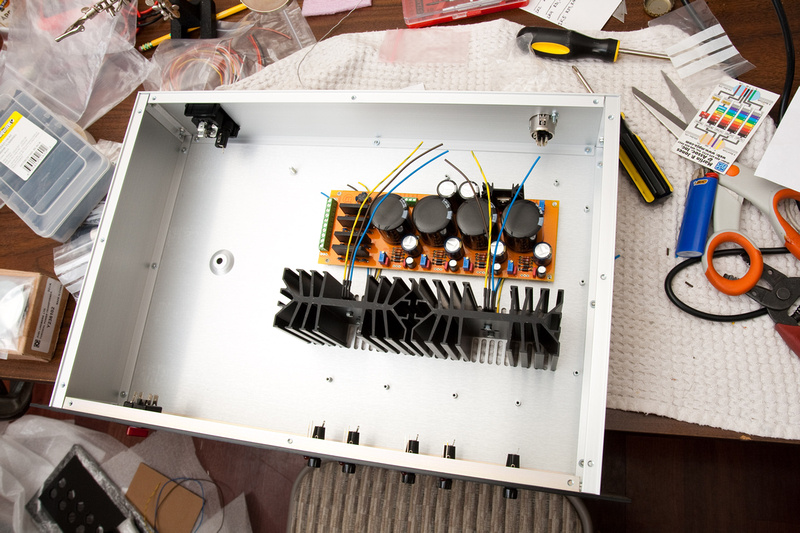

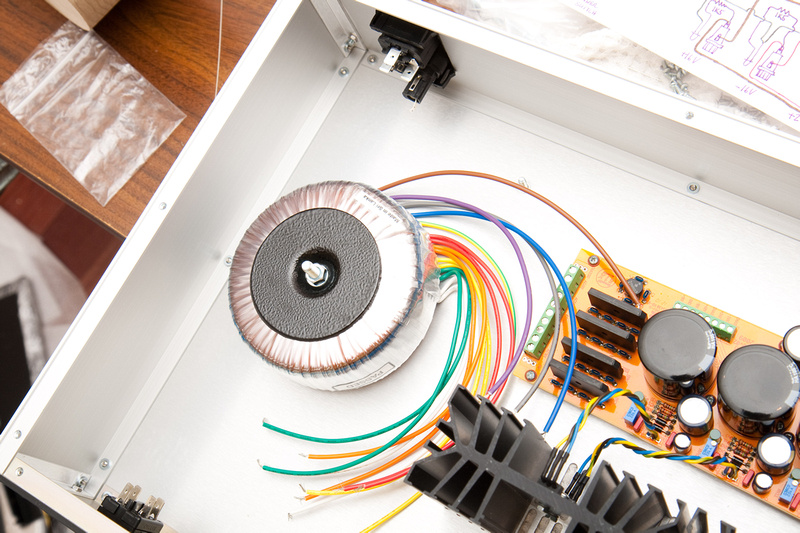

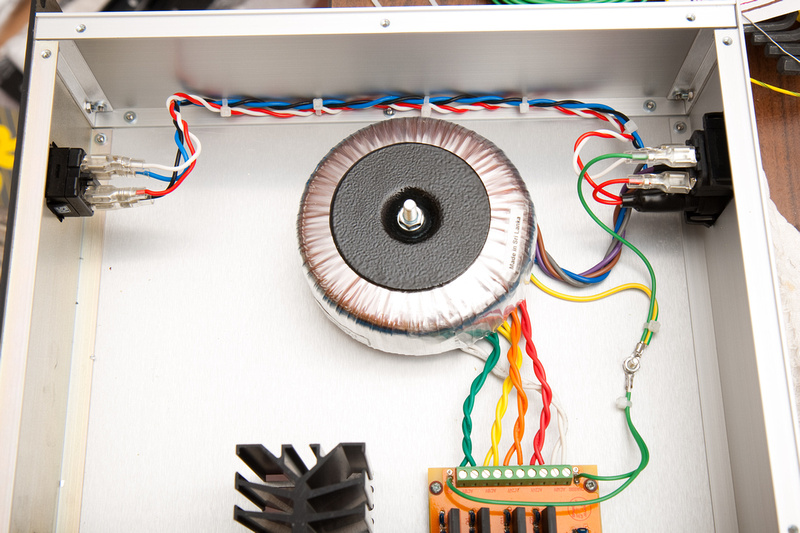

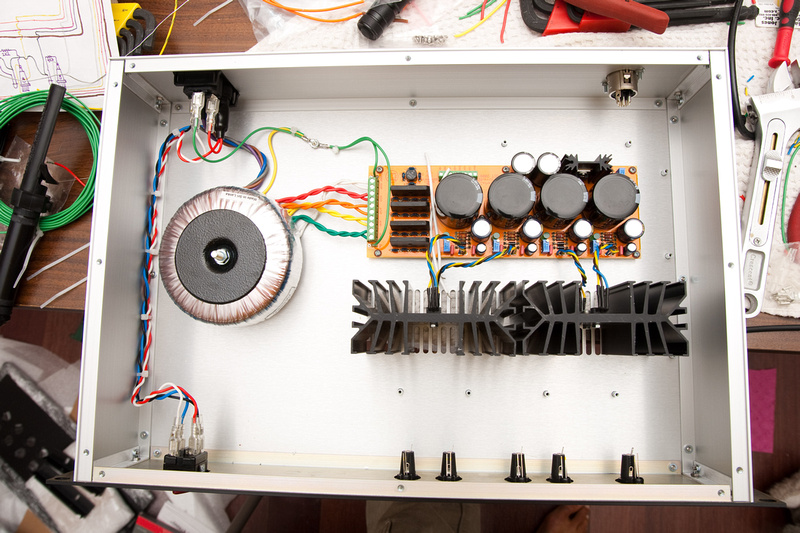

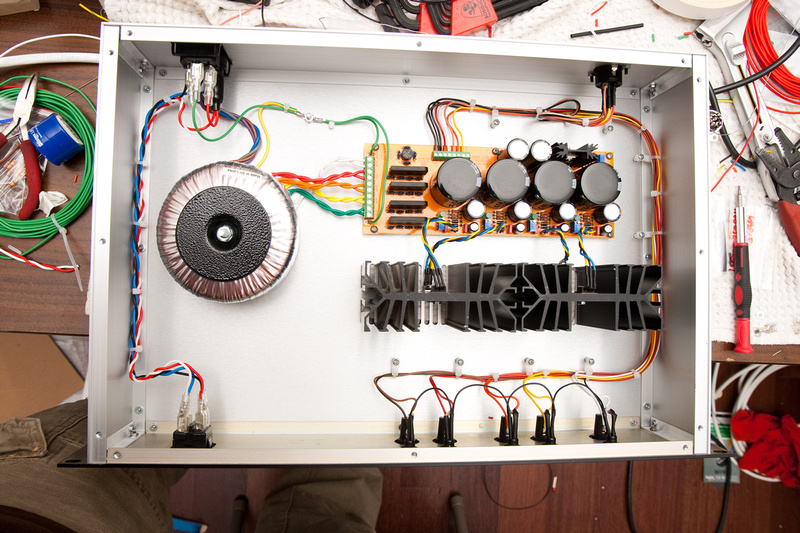

And, fire it up!

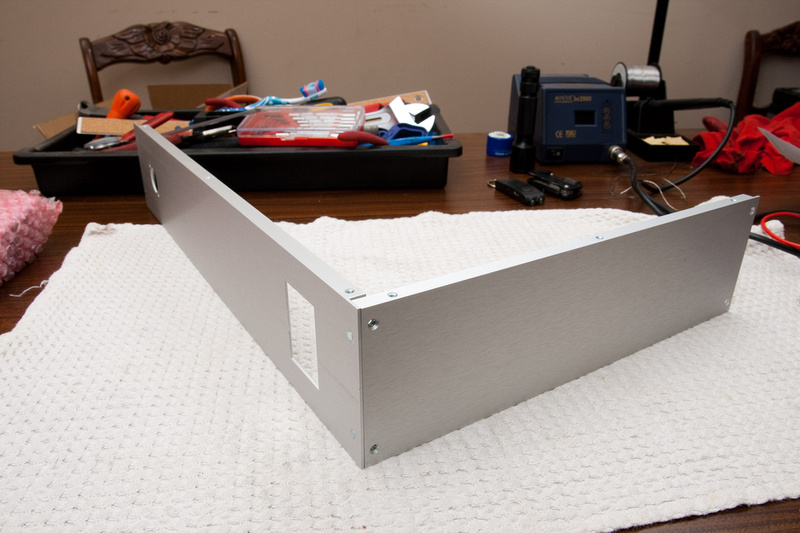

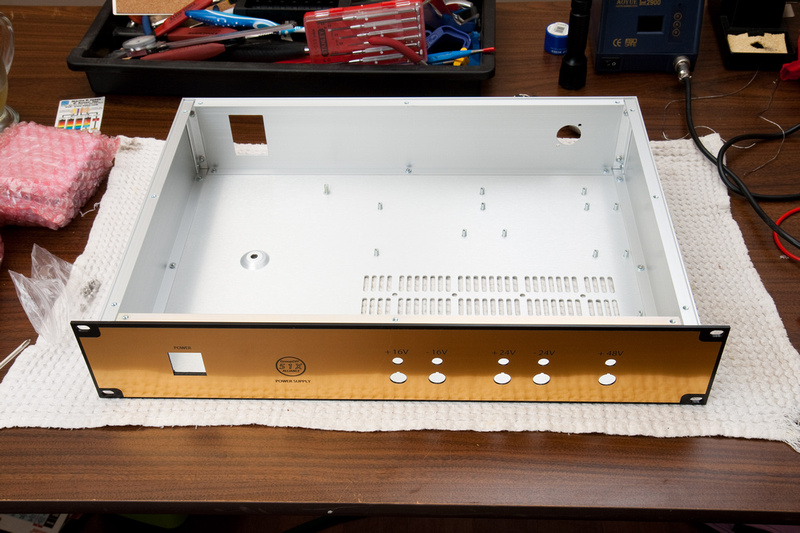

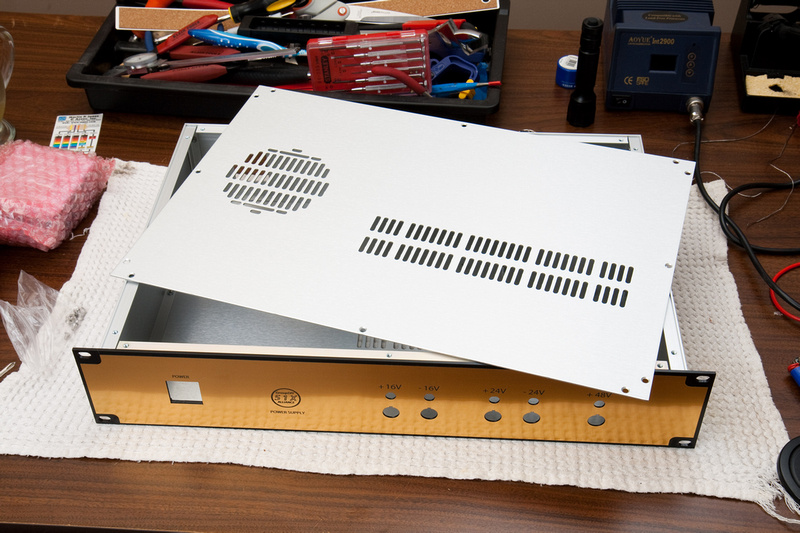

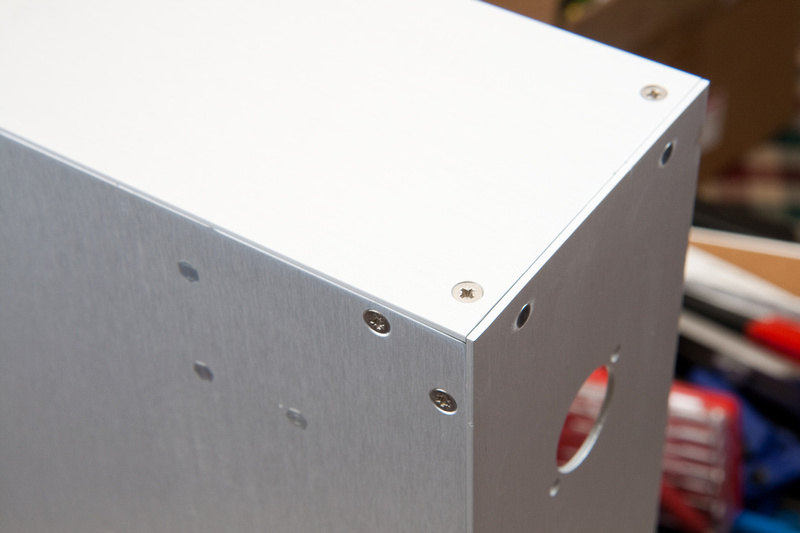

PSU complete. What a great 1st DIY project. I couldn't have been happier with the result and am glad to add my little contribution to the collaborative effort. The internals I think look decent. . . there are cleaner build examples, but I did what I could and hopefully did not embarrass myself but try to set a high bar and do this project justice.

Next, I just need to make my 7 pin DC power cable, and PSU unit 1 will be online and fully operational ;D

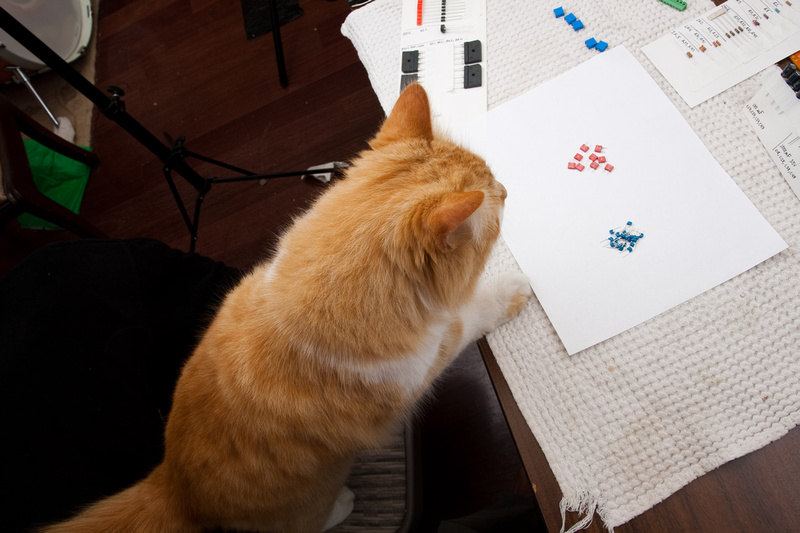

Humans win.