chunger

Well-known member

Melodeath00 said:Since the PSU connections were already shrink tube wrapped, I decided NOT to cut the connectors and rewire. Does Alctron not use high quality cable, or is it perfectly ok to re-use most of the cable connections? Same thing in te mic. I kept the B+, heater, and polarity control wires in tact. I added my own silver teflon for ground and bias. I did not shrink tube around the connections, but I bought some on Amazon just now, and will re-do those connections if need be.

The mic works as well. I am home for Thanksgiving and have no audio interface, but my brother is here with a portable stereo recorder that has an XLR input, so I know the mic passes signal fine. Polar pattern switching is not working, but I realized I forgot to bridge the rear and front backplate of the tester Alctron capsule, so I assume that would be why. I assume no damage would arise from my mistake, right?

I did not pay attention to which transformer wires went where. I still don't fully understand how you would keep track of polarity in regards to the transformer. All I know is Red goes to XLR and blue goes to the PCB. I will test the polarity when I get back to my studio and swap the blue wires if need be. That's all that matters, right? I noticed the Alctron was inverted polarity compared to my other mics in general, and I did not want to swap the audio wires in the PSU XLR connector since they were nicely shrink wrapped already,

I will probably install the Tim Campbell capsule tomorrow. Why do we test heater voltage at the mic, while we test B+ and Bias in the PSU? Shouldn't we test everything at the mic?

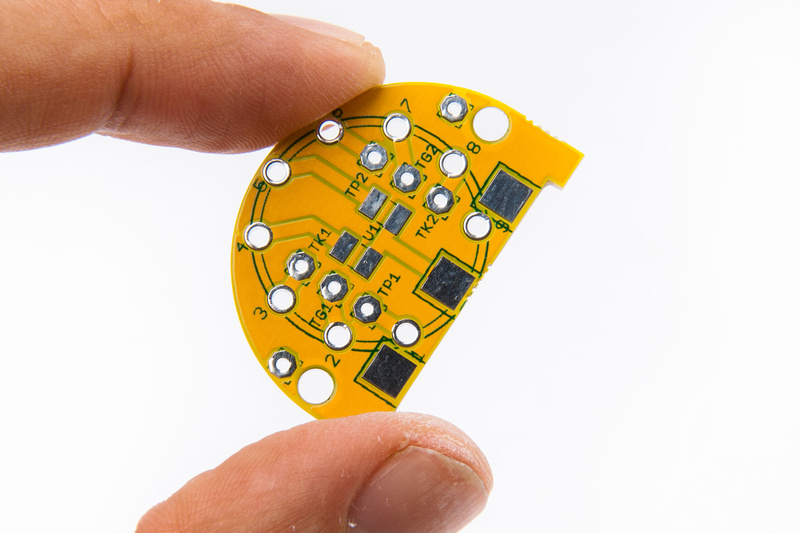

I'm also still confused about the capsule teflon stand-offs. Since the metal pin goes through the teflon and makes contact with the PCB, how does the teflon have any effect whatsoever? Why would it even matter to float those capsule connections, and why are we using the teflon standoffs? It seems all we're doing is wrapping teflon around the connection that is made to the PCB. How is this different from using teflon wire?

Stock wires should work fine in the PSU as long as you remember to unground the bias pin and add a wire which you did. Heat shrink probably optional especially since the surrounding pins all have the original heat shrink still.

The teflon pins are supplied in the kit just in case you want to isolate the hi Z connections. . . if so, you can drill out/enlarge the holes and press fit the teflon pins. Then, make the required connections with teflon wire. Also, pins are convenient because you will not have to clean the PCB again when you change capsules. . . which most people will do at least 1x in the build process.

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)