Andy Peters

Well-known member

I've been working on a simple monitor controller design.

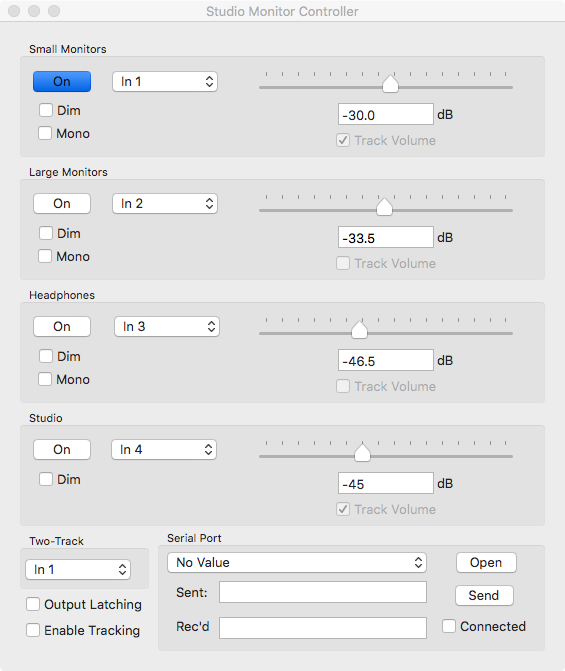

It has four stereo line-level inputs.

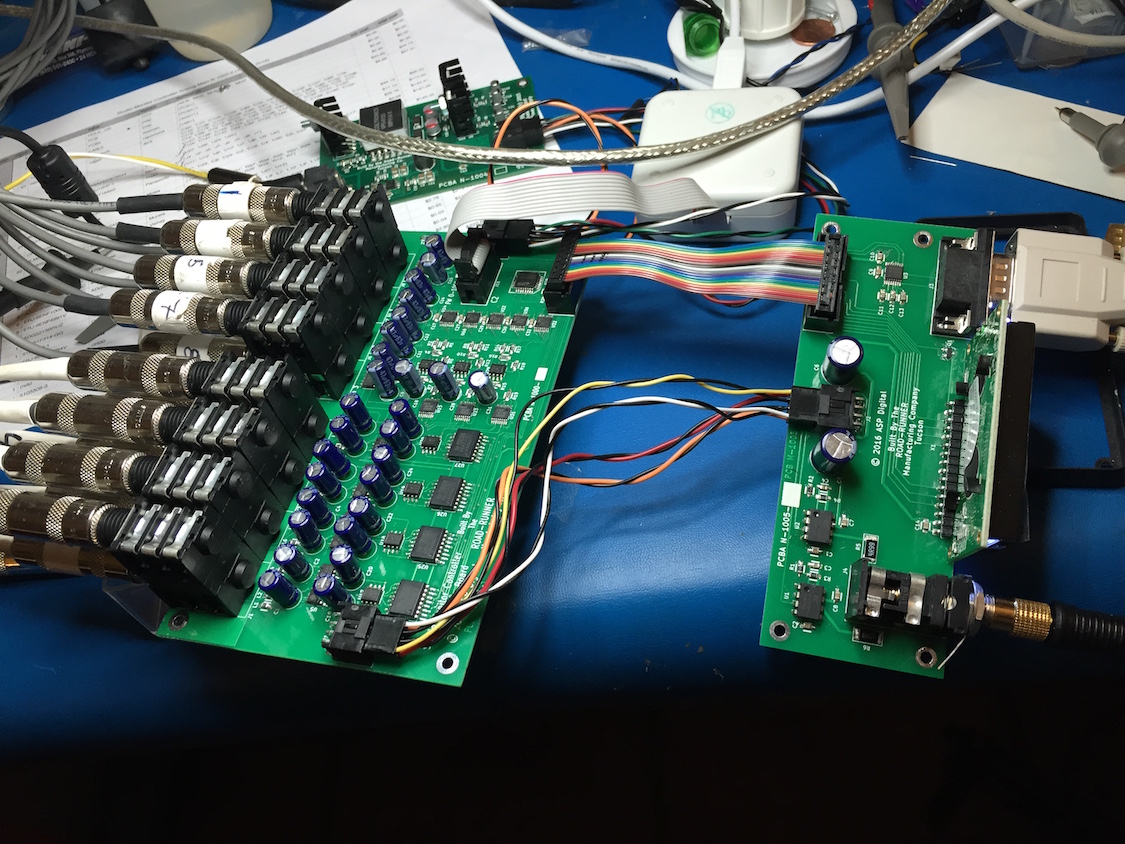

It has five stereo outputs. "small" monitors, "large" monitors, headphones, studio feed, and two-track feed. All but the two-track feed have volume control capability using PGA2320. The monitors and headphone outputs can be switched to mono. Any input can be routed to any output.

There is a small front-panel board which has the headphone amp and an LCD (for status) display. It has a DE9 jack which speaks standard RS232 to the remote control unit, which is still being designed. It can also connect to a computer's standard RS232 port.

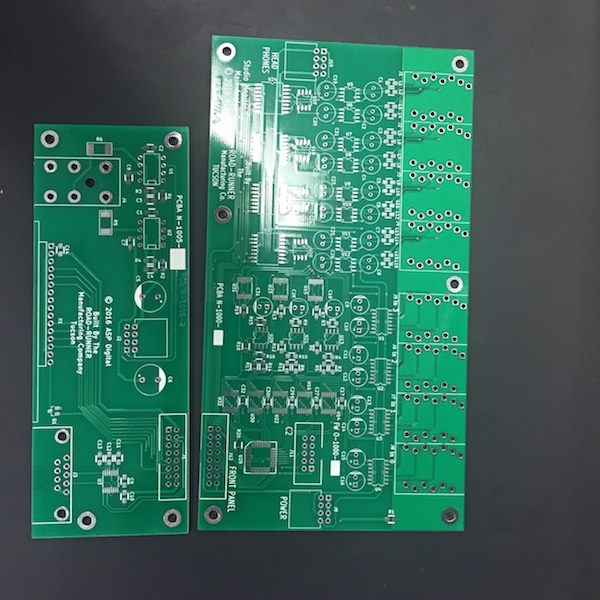

Here are the PCBs. I did the design with Kicad on a Mac. Both boards are two layers, the board on the right has a whole lotta passives on the bottom.

I did the microcontroller programming on the Mac, too, with Silicon Labs' Simplicity Studio IDE (which has the Keil compiler under the hood).

It has four stereo line-level inputs.

It has five stereo outputs. "small" monitors, "large" monitors, headphones, studio feed, and two-track feed. All but the two-track feed have volume control capability using PGA2320. The monitors and headphone outputs can be switched to mono. Any input can be routed to any output.

There is a small front-panel board which has the headphone amp and an LCD (for status) display. It has a DE9 jack which speaks standard RS232 to the remote control unit, which is still being designed. It can also connect to a computer's standard RS232 port.

Here are the PCBs. I did the design with Kicad on a Mac. Both boards are two layers, the board on the right has a whole lotta passives on the bottom.

I did the microcontroller programming on the Mac, too, with Silicon Labs' Simplicity Studio IDE (which has the Keil compiler under the hood).