skal1

Well-known member

Hi indiehouse,

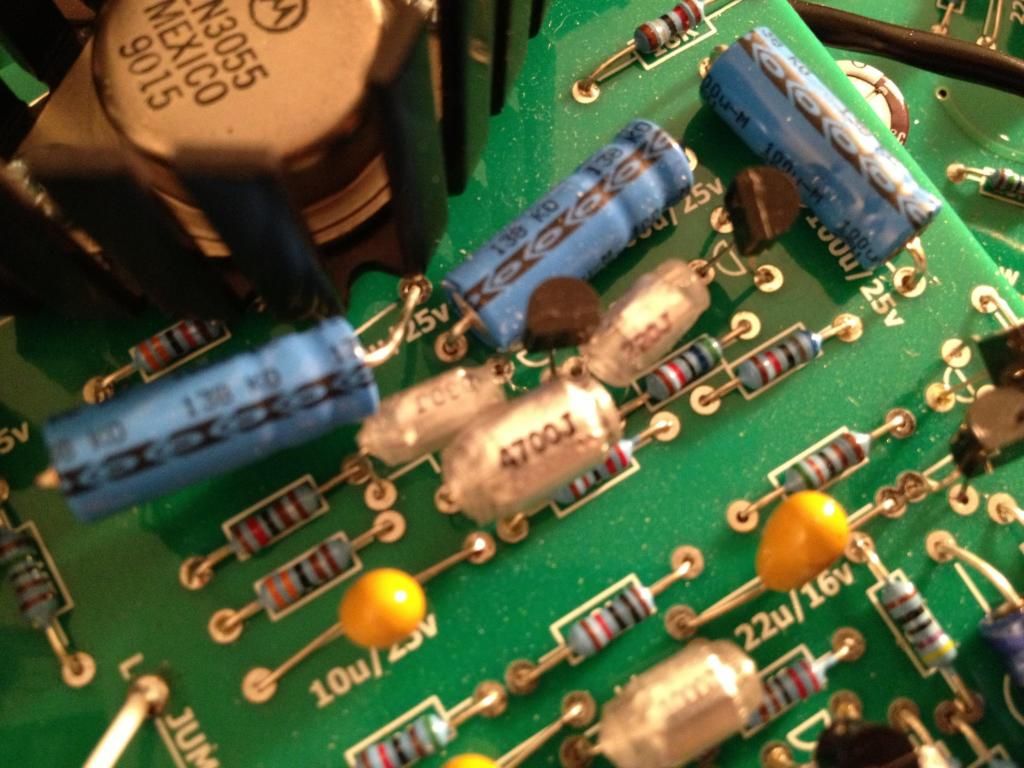

just a suggestion put some heat sinks on those regs isolated of course,and see if you have the same probelm , it might be that the regs or going into thermal sunt down , just my 2 pence..

skal1

just a suggestion put some heat sinks on those regs isolated of course,and see if you have the same probelm , it might be that the regs or going into thermal sunt down , just my 2 pence..

skal1

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)