Edward

Well-known member

Echo North said:ILOVE1176 said:I have no experience reading scematics drawings?

Now is a great time to start!

MNATs even labeled the pots to make it clear.

Haha, i just was about to upload the exact same screenshot!

Echo North said:ILOVE1176 said:I have no experience reading scematics drawings?

Now is a great time to start!

MNATs even labeled the pots to make it clear.

ILOVE1176 said:Ok guys, here is my last question for now.

I struggle to find the exact material where I stay to use for wiring my project BUT I have mined some 20AWG cable from a PC Power supply. I have been using it so far...... Would it be suffecient? I know its not the recommended 22AWG but will this suffice?

Regards

Echo North said:Also, using your meter, test to make sure that GRN on the ratio PCB has continuity to pad 22 on the main board and NO continuity to BLK (ground) when in GR mode.

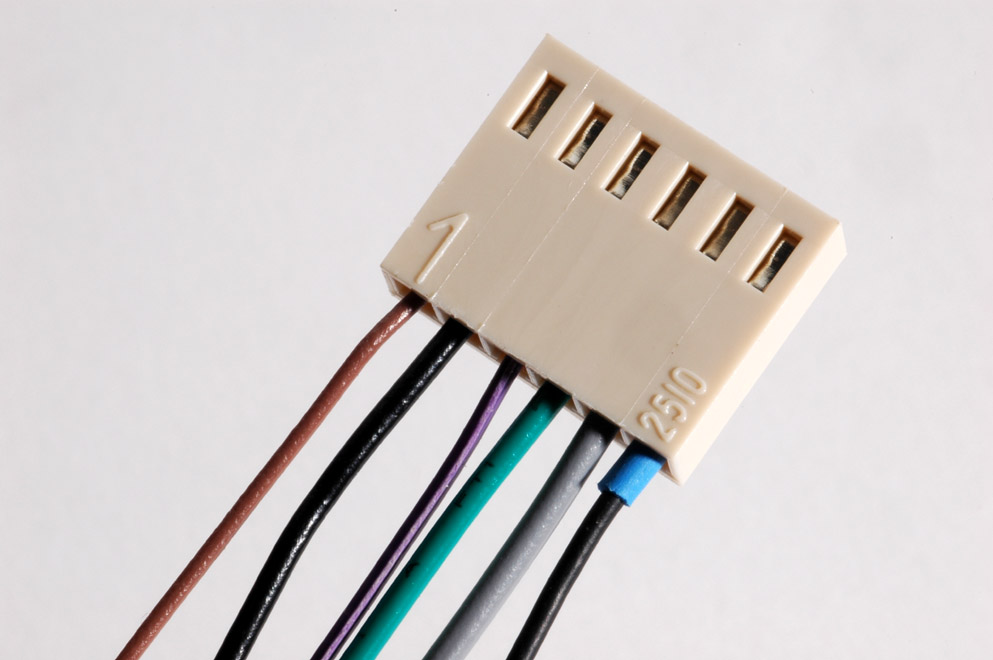

hi you !!sr1200 said:depends on how big the piece you're fitting it into is. Without knowing the size of the connector, cant give you a part.

dbonin said:I did the q-bias calibration, no problems.

The meter circuit adjustment? Not so much.

I'm using the 2k pot for the "0" set and the 2k trim on r75.

Ignoring the VU meter, the best I can do is 0.50 v on r74. No matter what I do I can't get r74 down to 0v, let alone with the VU near zero.

When I dial in .5 V on r74 the VU needle is pegged past +3.

I've read others have had luck with a 5k trim on r75? If i just get a 5k trim and I get the calibration to work am I just masking some other issue I have introduced earlier, or is that moot at this point?

Thanks for any pointers!

dbonin said:regarding http://mnats.net/files/1176REVD_VOLTS.pdf

aside from turing the power on, is there anything that needs to be done prior to testing the points? No input signal applied?

Also, if I'm using 3708's and he was using something else, would that cause the voltages to be way off?

I assume as long as they are in the same ball park we're ok?

I'm testing all points with my common lead on ground pad 16...

As indicated on the original schematic, some details regarding the transistors should be noted. Select Q12 and Q13, matching hFE within 10% (the absolute value is not critical). This will allow proper calibration of the meter driver circuit and correct operation once calibrated.

Q7 through Q10 must be selected for an hFE of 250 or above.