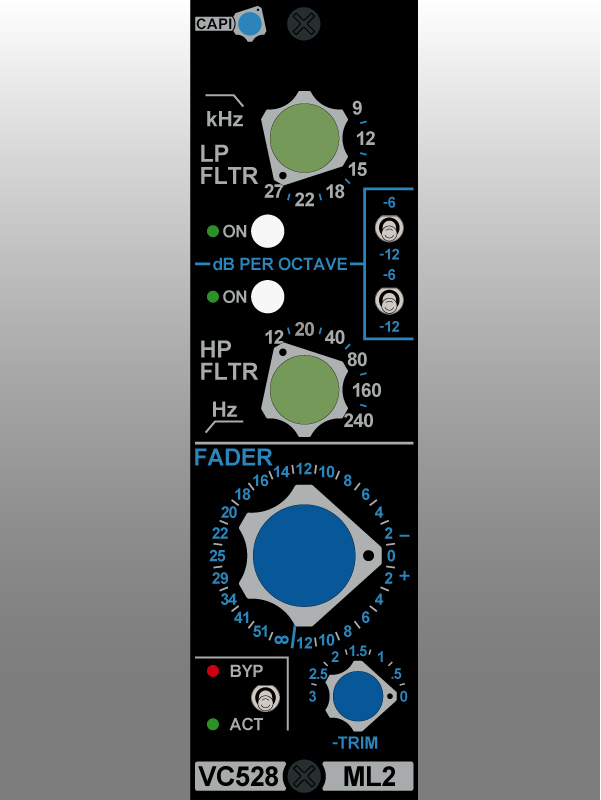

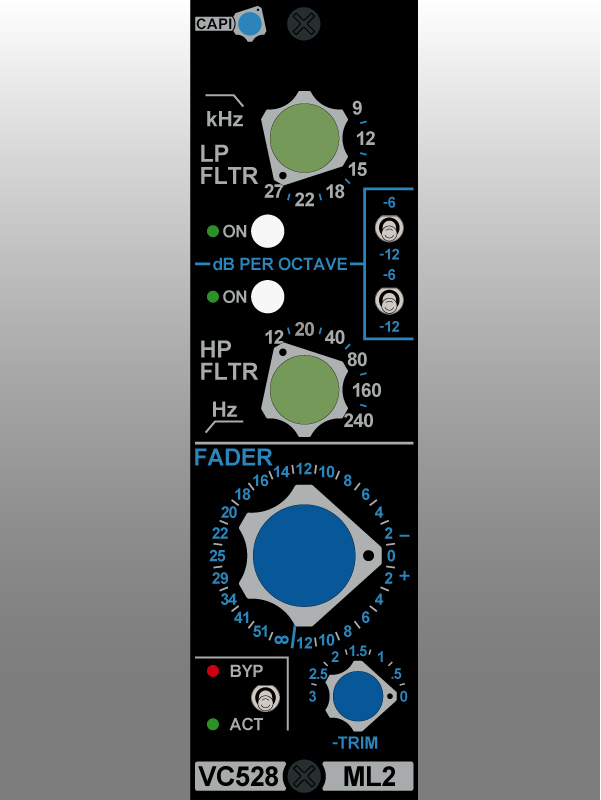

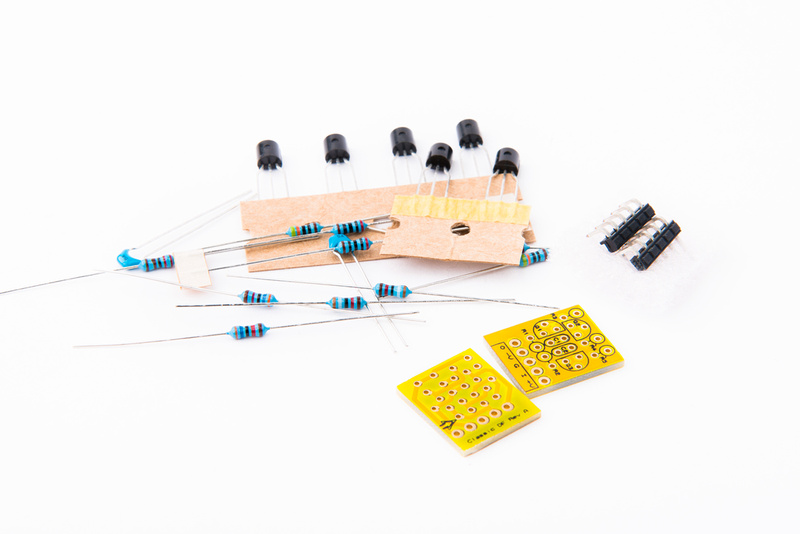

OK. . . a bit late to the party, but here is a walk-through of the ML2 build top to bottom. First, let's have a look at the kit components as they come out of the box. This revision really simplifies the assembly of the Missing Link units and moves this kit from one of the more difficult and involved CAPI builds to an exponentially easier project.

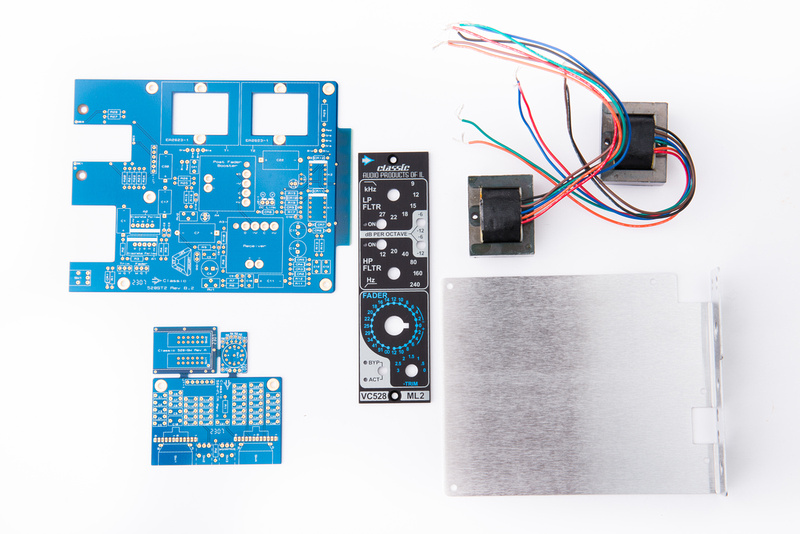

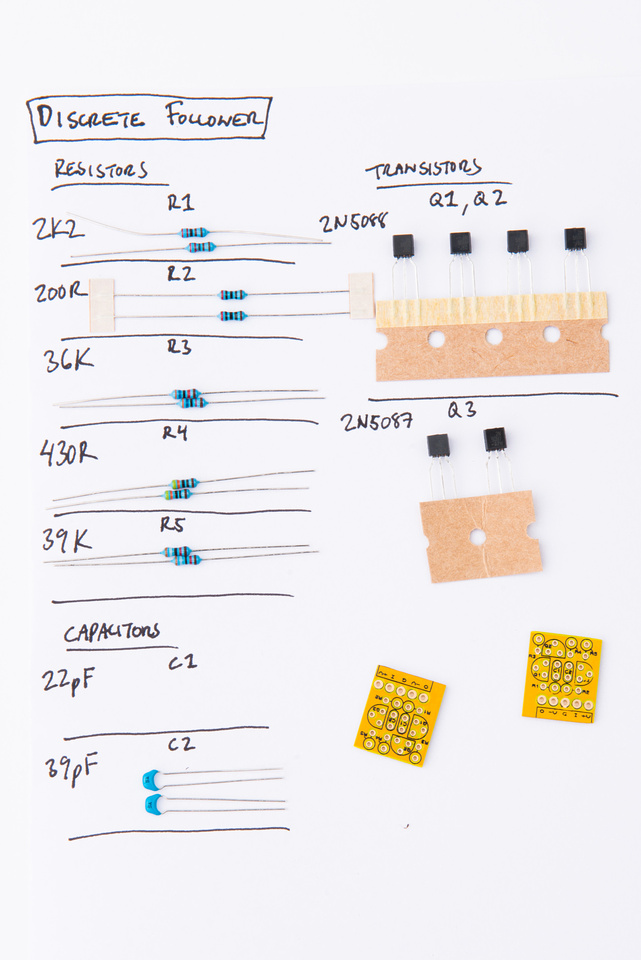

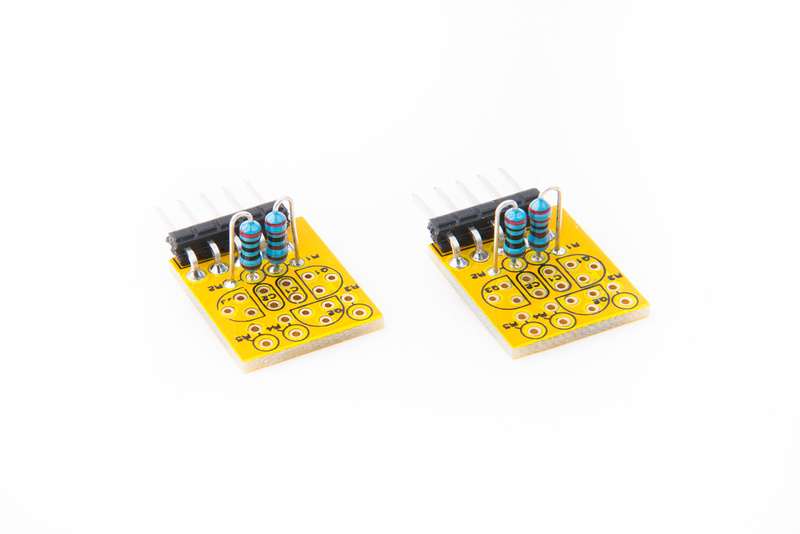

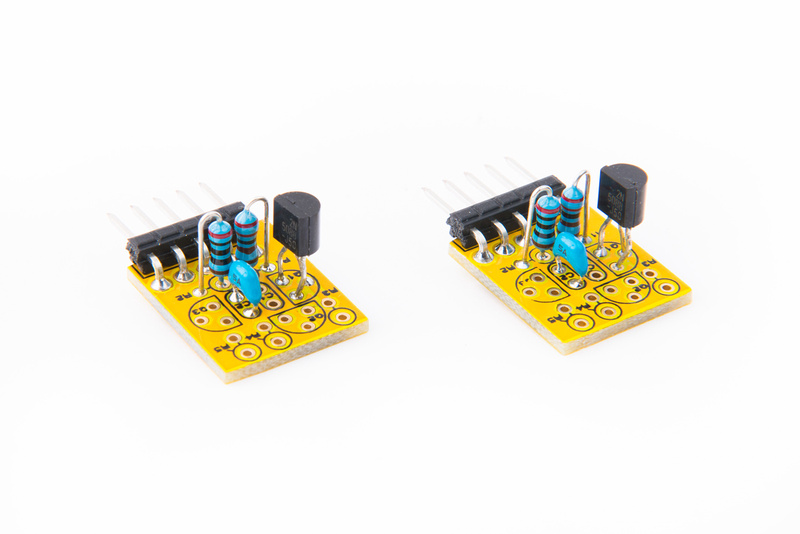

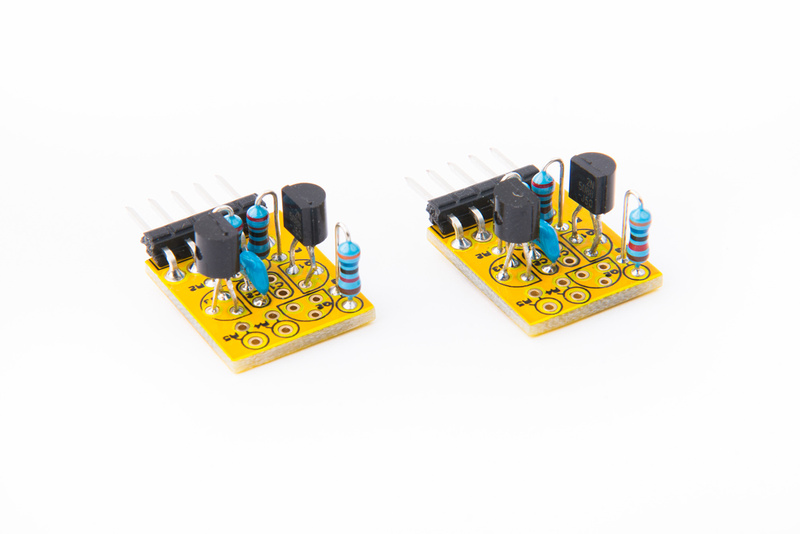

First, assemble the 2 discrete follower boards. The parts are contained in this bag.

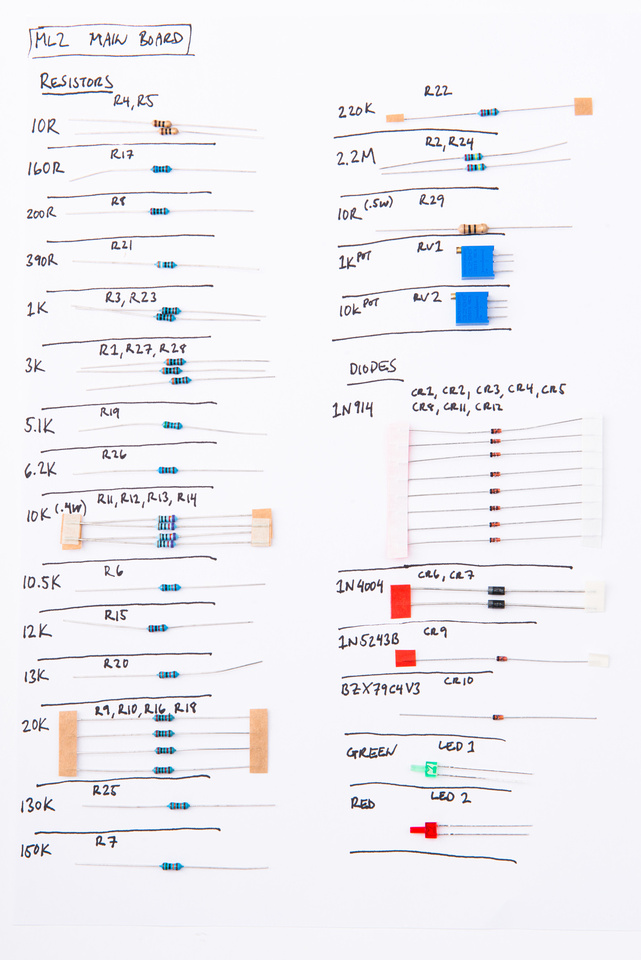

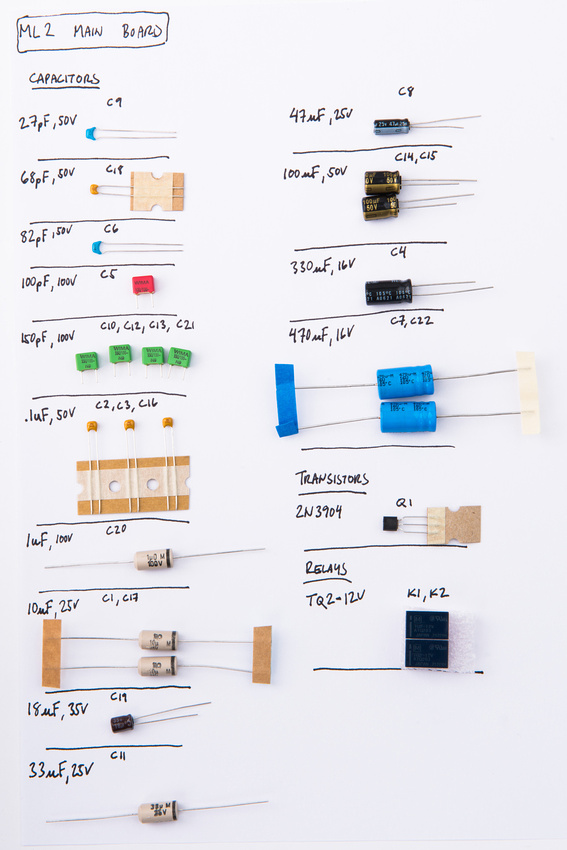

It is helpful to organize and sort the parts before assembly.

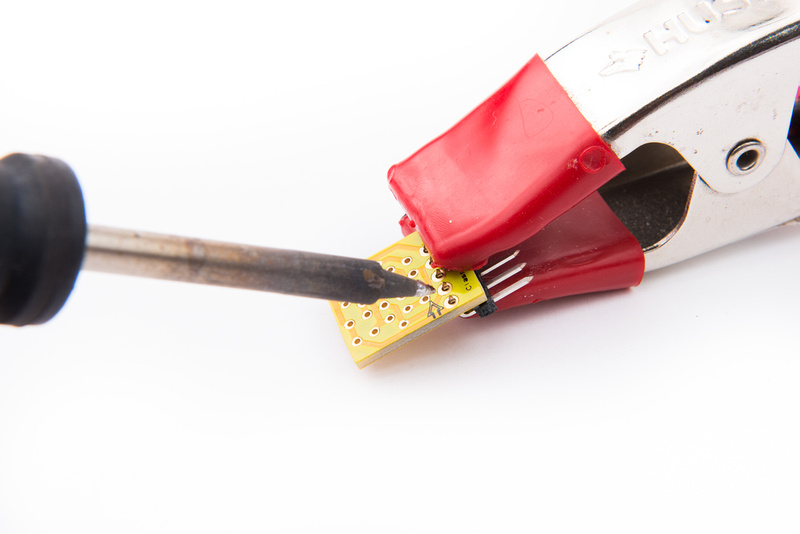

Once all of the components are identified, begin by installing the header. I clamp the header tight to the PCB and leave 2 pins exposed on one side and solder those first.

Then, re-position the clamp to expose 2 pins on the opposite side and solder.

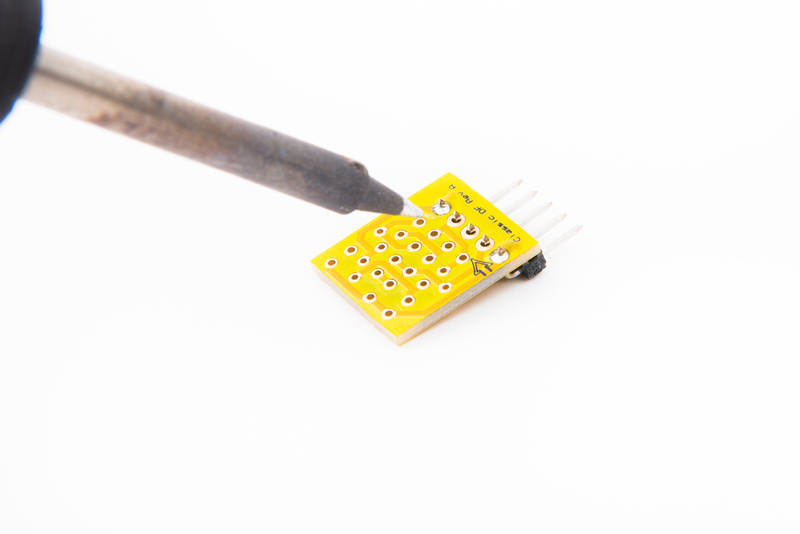

And solder the pins in the middle with the clamp removed after the outer 4 pins are secured.

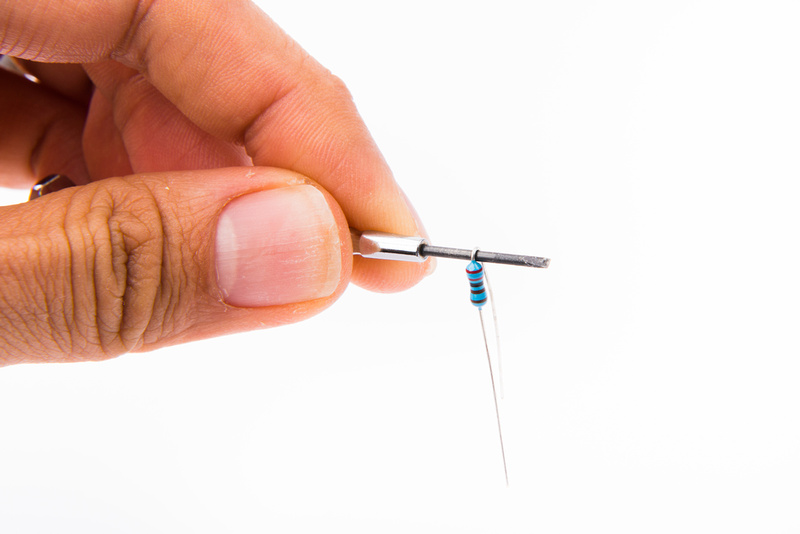

A convenient way to bend the resistors for vertical mounting is to use a small screwdriver .

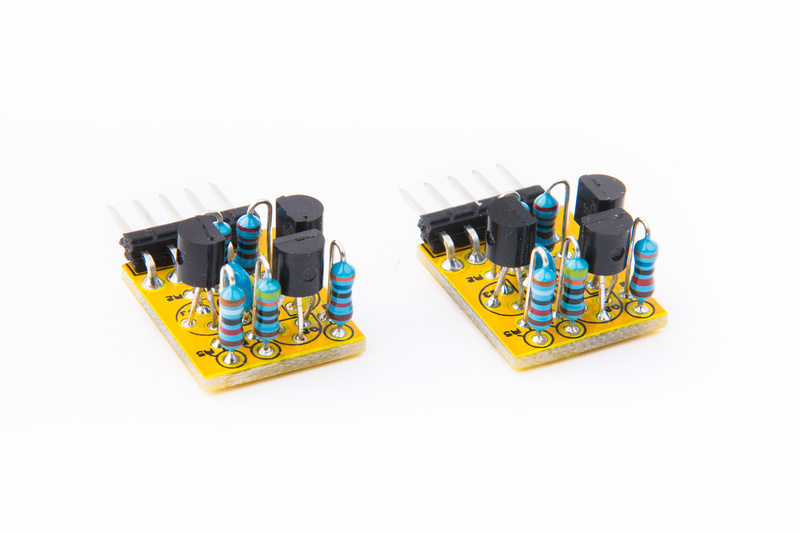

And, we populate the discrete follower PCB's according to the BOM and silk screen markings.

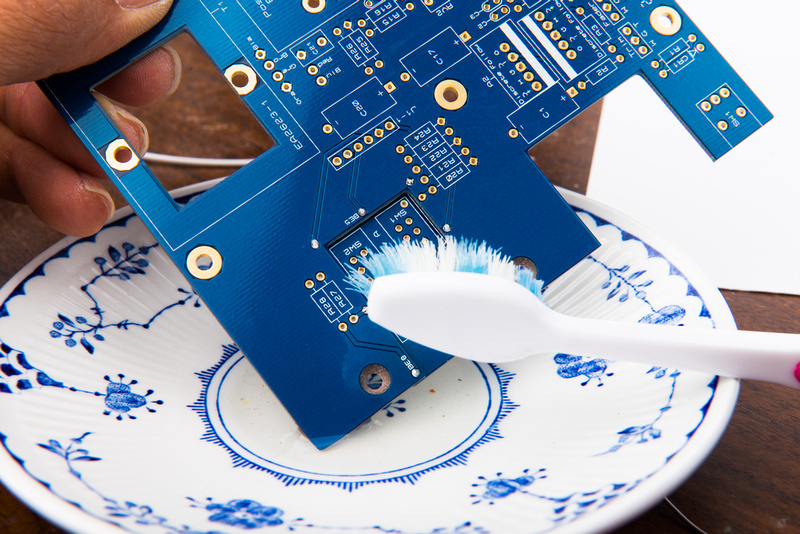

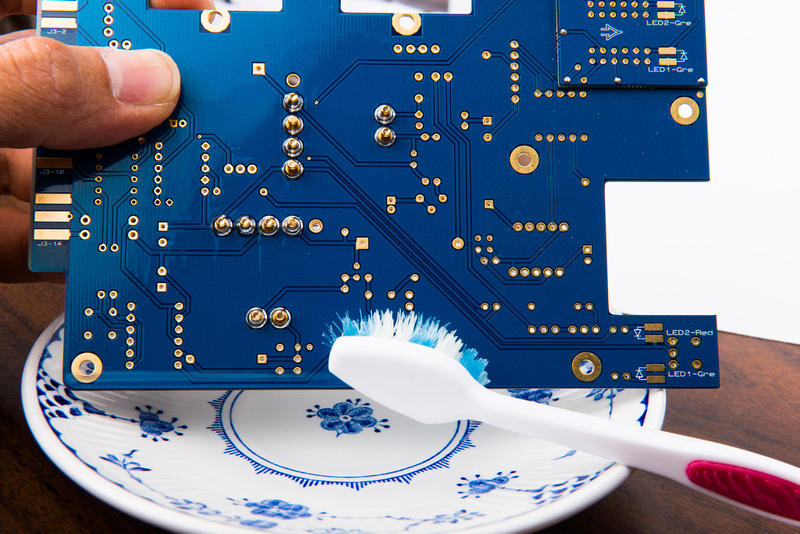

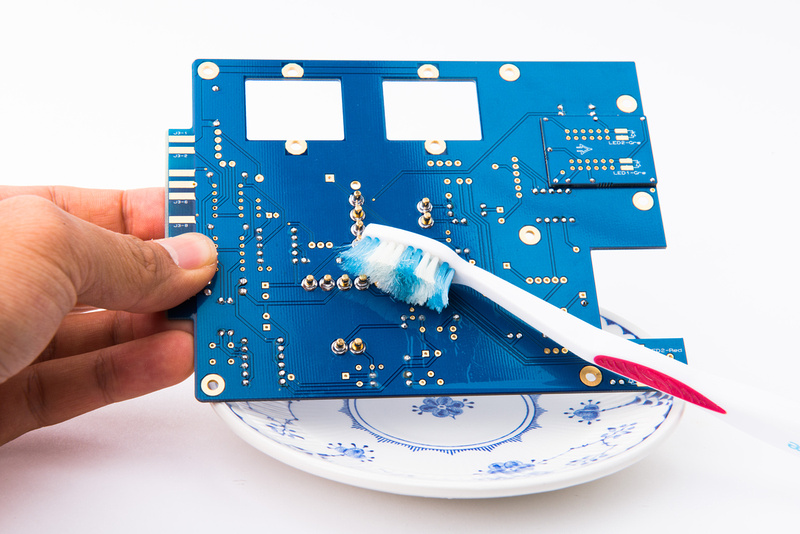

It is probably optional in this particular build, but I use some 90% isopropyl alcohol and a toothbrush to dunk and scrub the PCB's to remove all of the solder flux. None of the components on the discrete follower PCB are susceptible to damage from the IPA solution. If you do decide to clean the board, do not go half way and just dab a few drops of alcohol on the board. It will just smudge the flux everywhere and make a sticky mess. Commit and scrub the back side down thoroughly with a toothbrush until all of the flux is dissolved and removed.

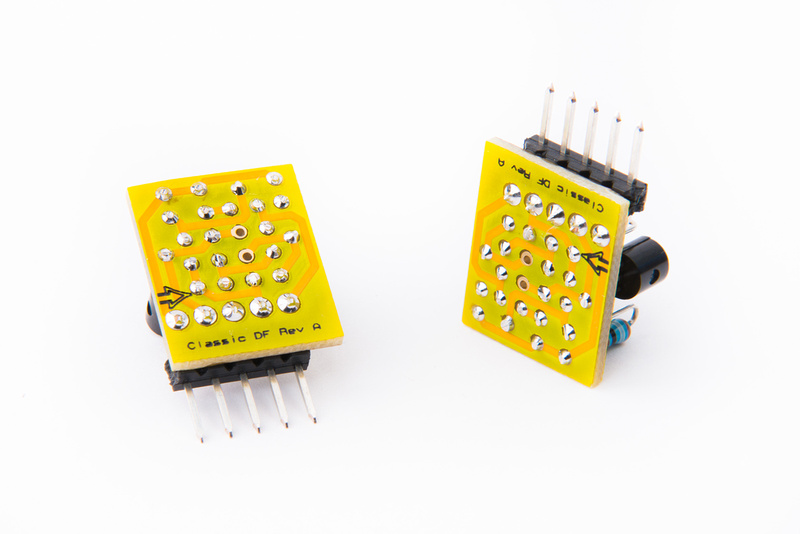

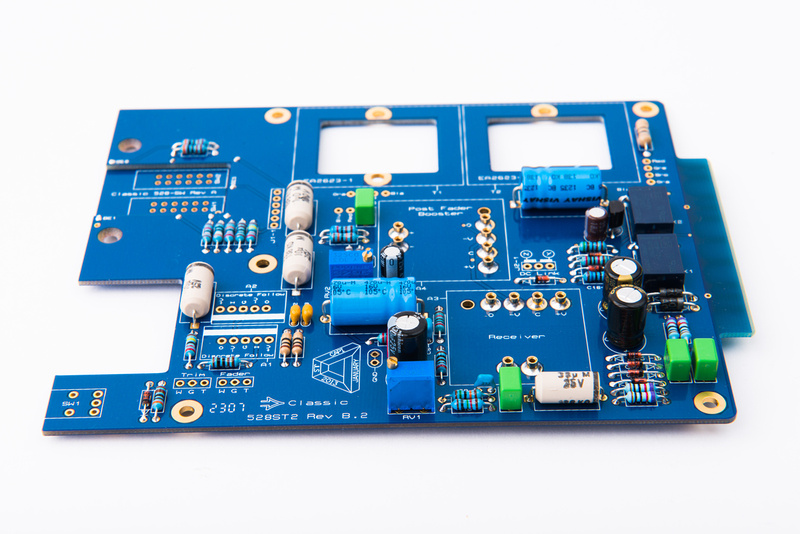

Discrete follower boards assembled and all cleaned up.

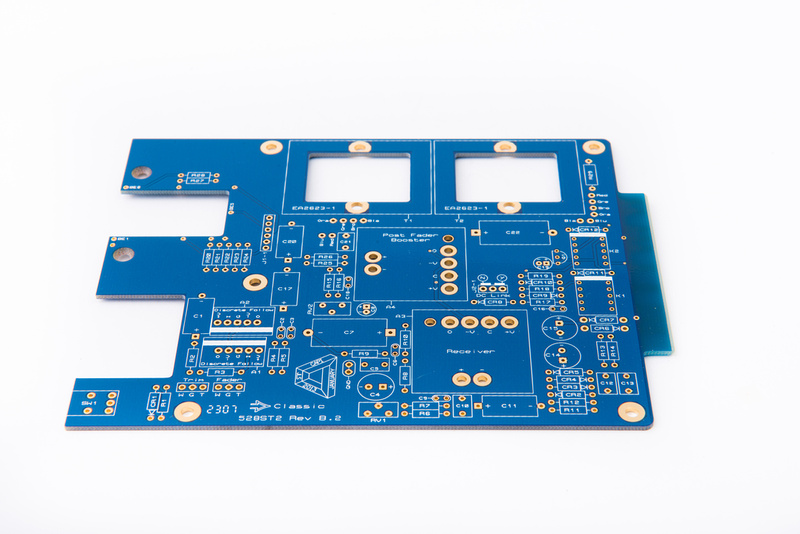

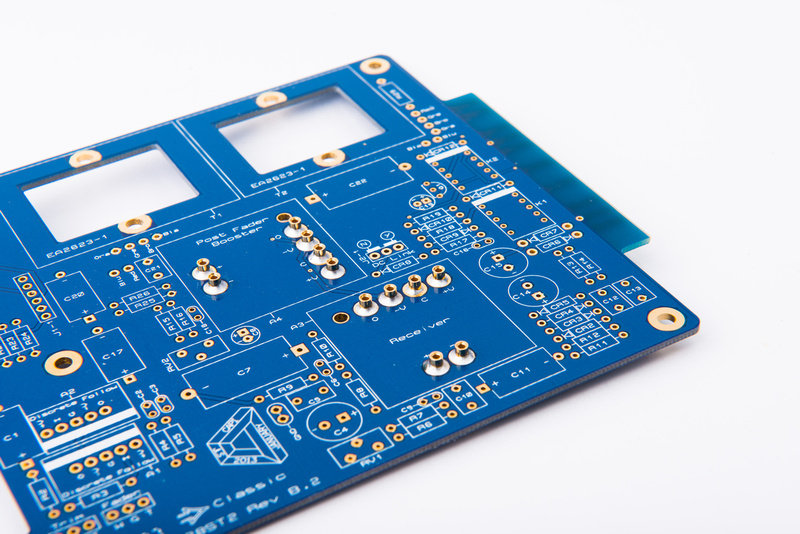

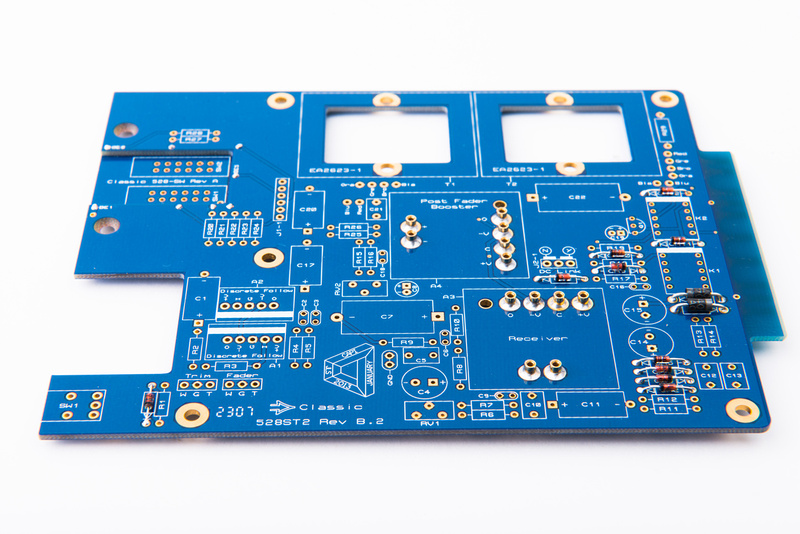

Next, we procede to the main PCB.

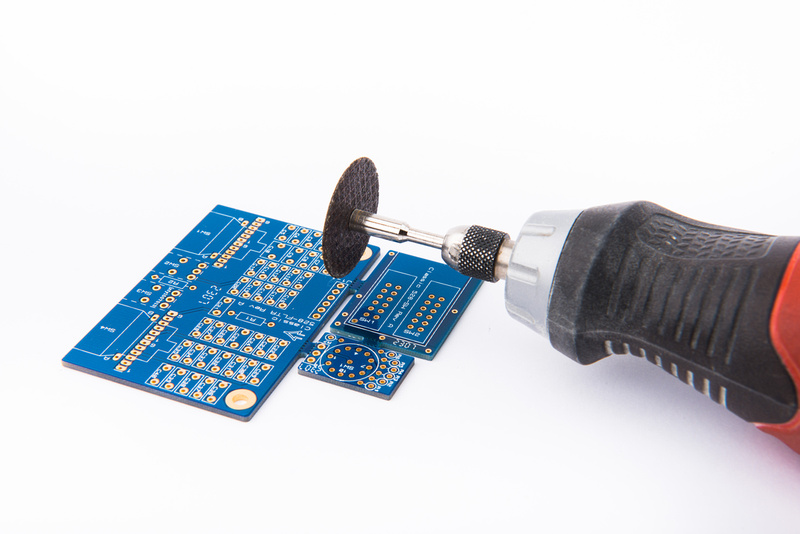

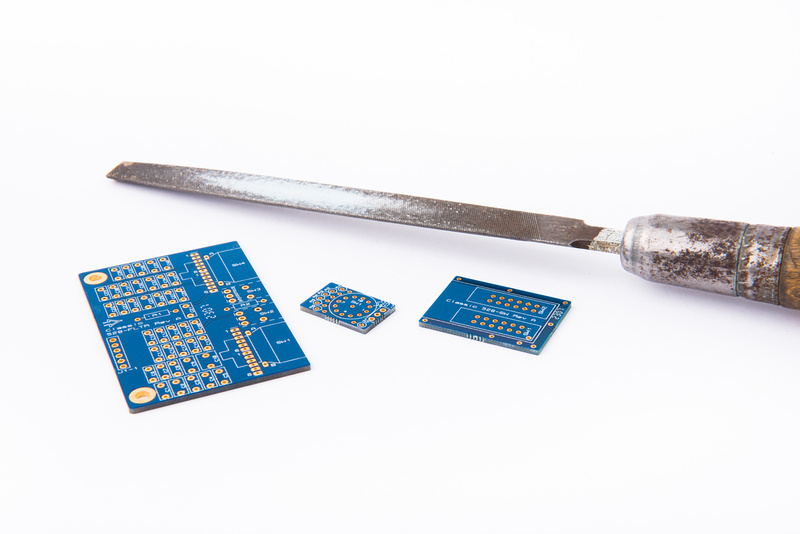

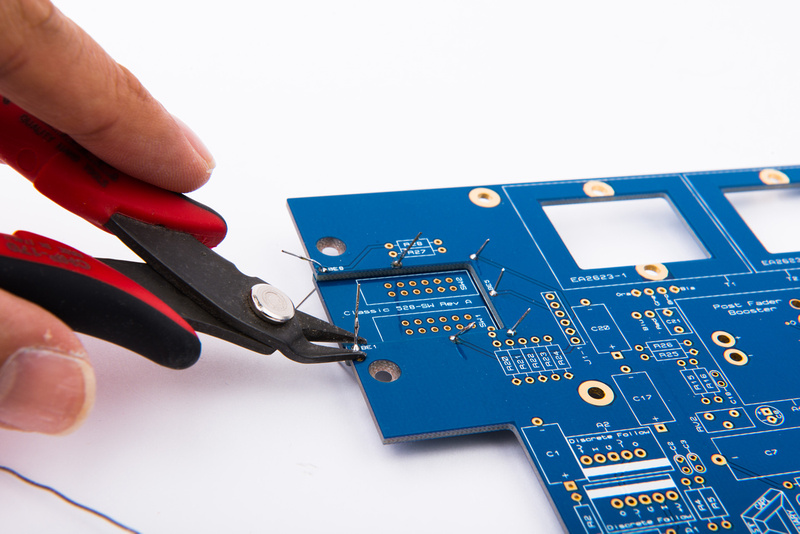

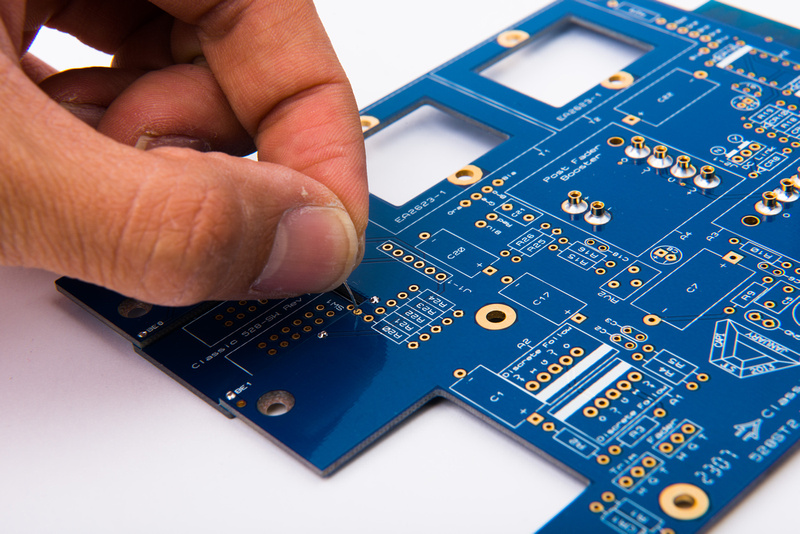

The first step in assembling the main PCB is to attache a small sub-PCB for switches. So, start by cutting apart the sub-PCB's and cleaning up the edges with a file.

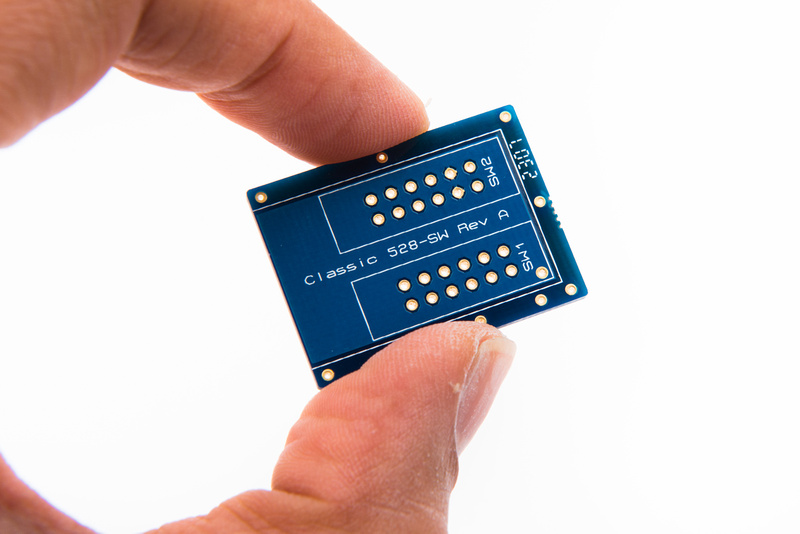

This is the board we are after.

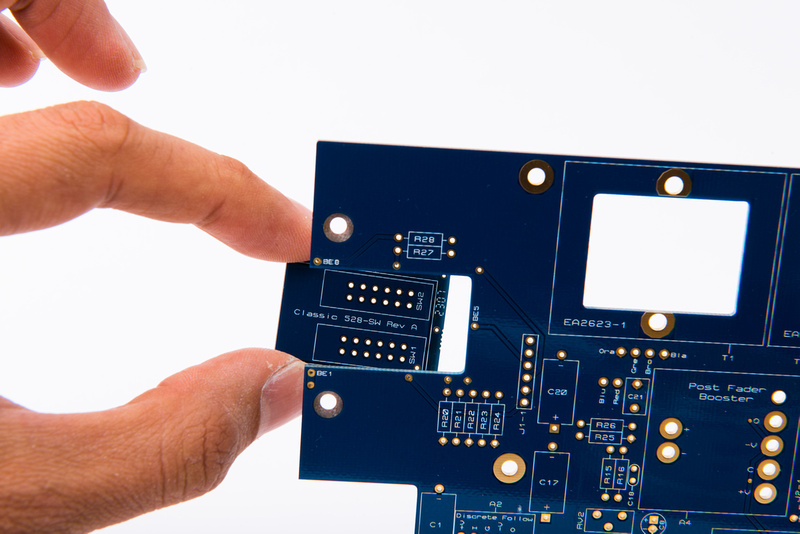

And it fits onto the main PCB like this:

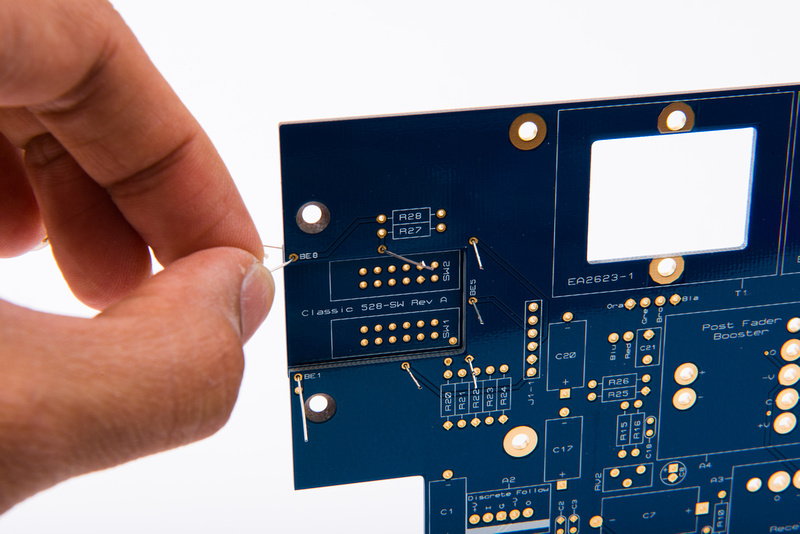

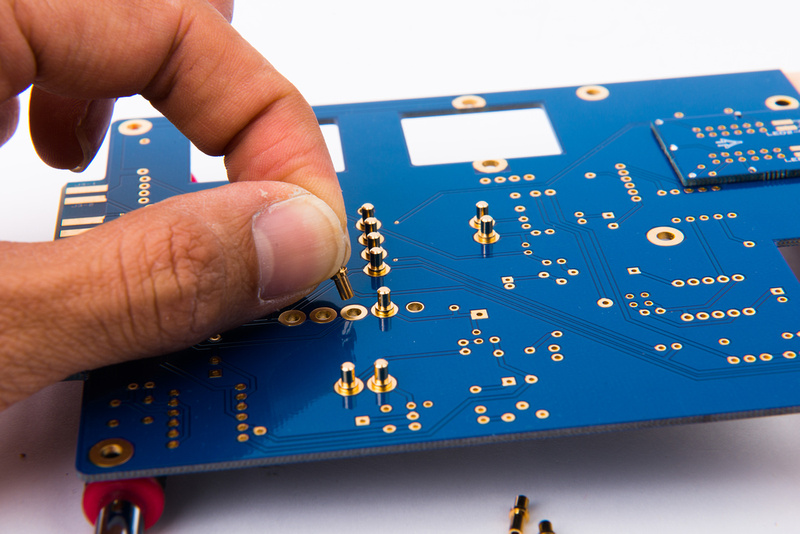

The board is mounted via plated through holes with component cut-off leads.

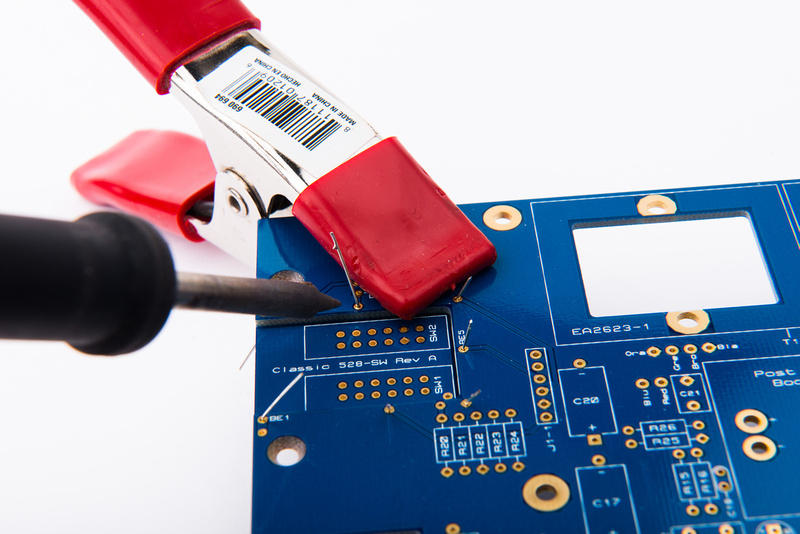

Once the leads are set in place, the board can be clamped and soldered.

And the excess trimmed off.

If you have decided to clean off the solder flux from the boards, now is as good a time as any to scrub off the flux with 90% IPA solution.

Next, locate the small bag containing the hardware.

And locate the discrete op-amp sockets.

Insert into the main PCB from the back side and solder in place. Note: significant heat may be needed to get these pins started. Aim to flow enough solder into the sockets to bleed onto the back side, but not so much that it goes all the way down and intrudes into the actual pin interface area.

And, while there are few components on the main PCB, it is easy to scrub flux off of the board at this stage.

I also noticed that I missed one junction point for the sub-PCB that mounts the push switches, so I insert that now.

Next, locate the bag with the electronic components to populate the main PCB.

And, we identify the components and organize them for easy access to avoid mistakes.

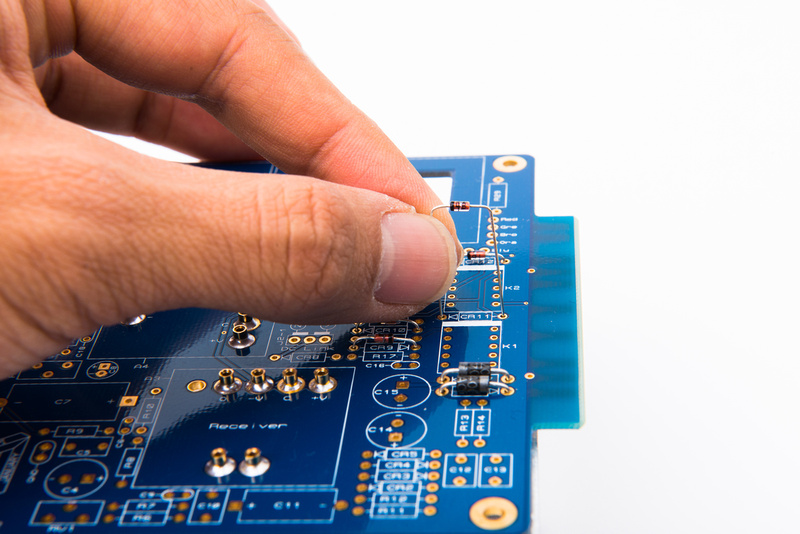

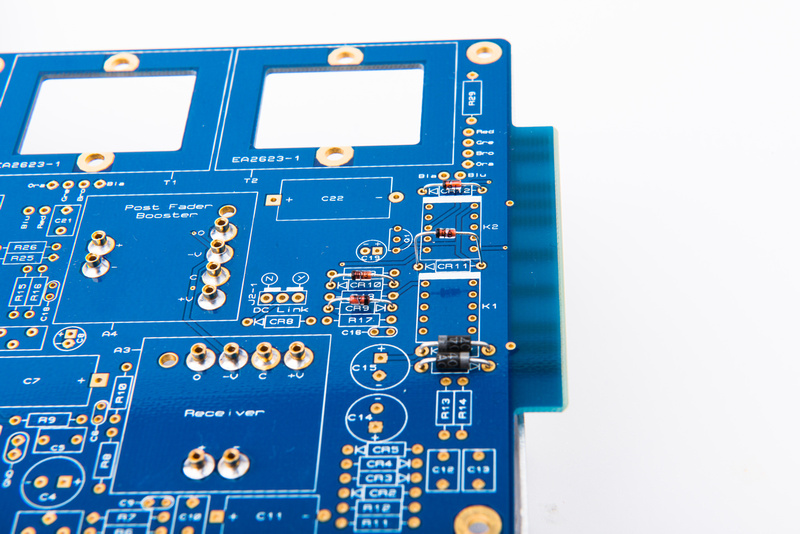

Pay particular attention to the small diodes because the markings are very hard to read. CR9 looks like this:

And CR10 looks like this:

CR1-CR5, CR8, CR11, and CR12 look like this:

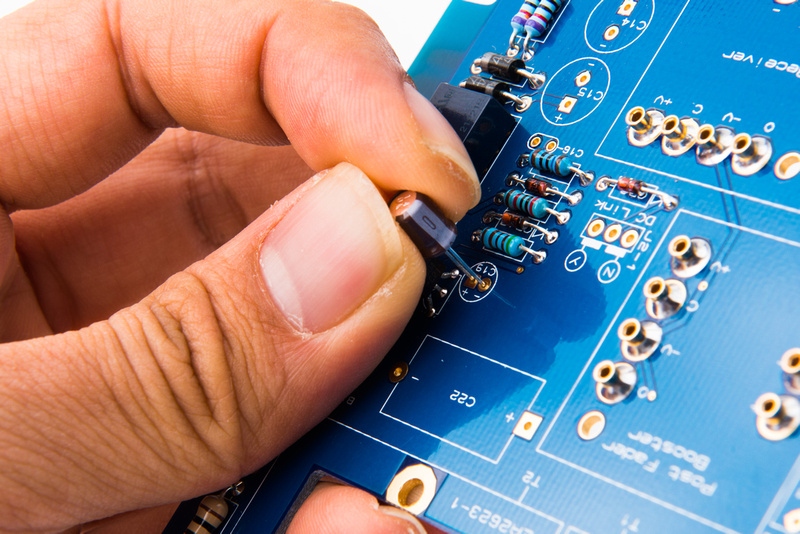

Next, populate the diodes making sure to set the side with the perpendicular line on the component facing towards the silk screened triangle on the PCB.

Take the time to confirm proper orientation of all the diodes.

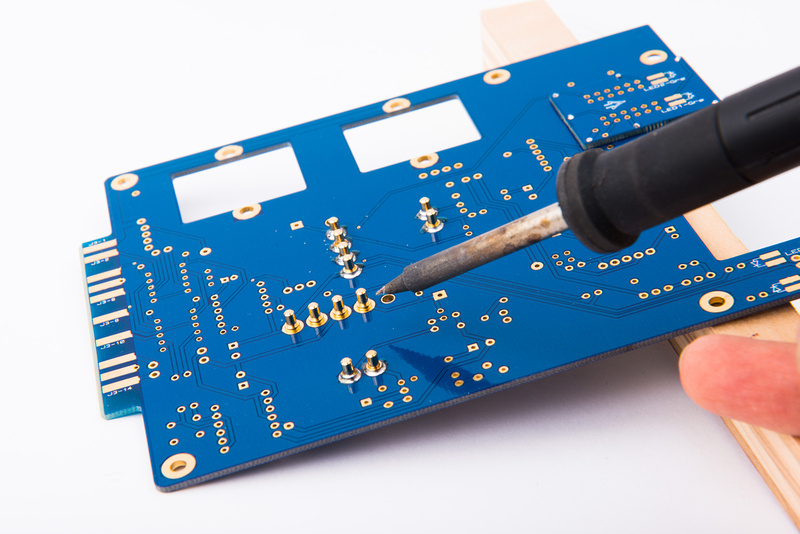

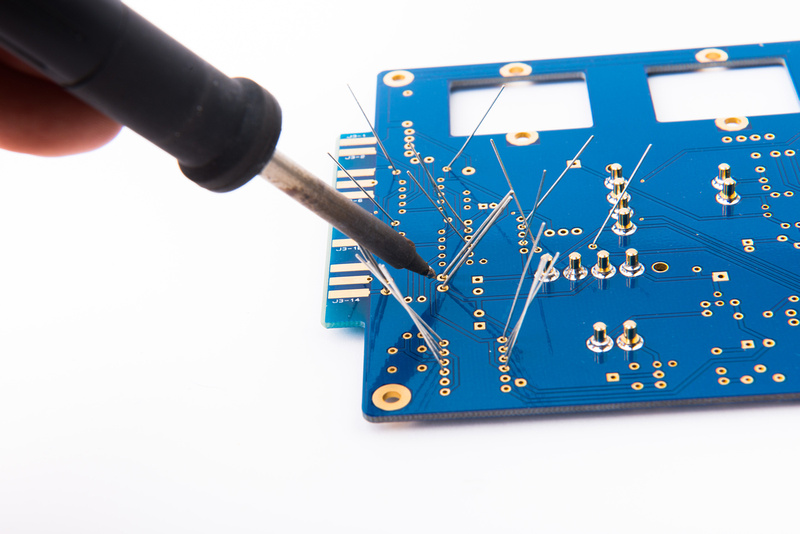

Bend the leads sharply near the PCB to hold the diodes in place and then solder each connection. The aim is to keep the iron on the piece as short as possible while flowing a nice bead of solder that transfers a to the opposite side of the board, so both sides have a smooth fillet.

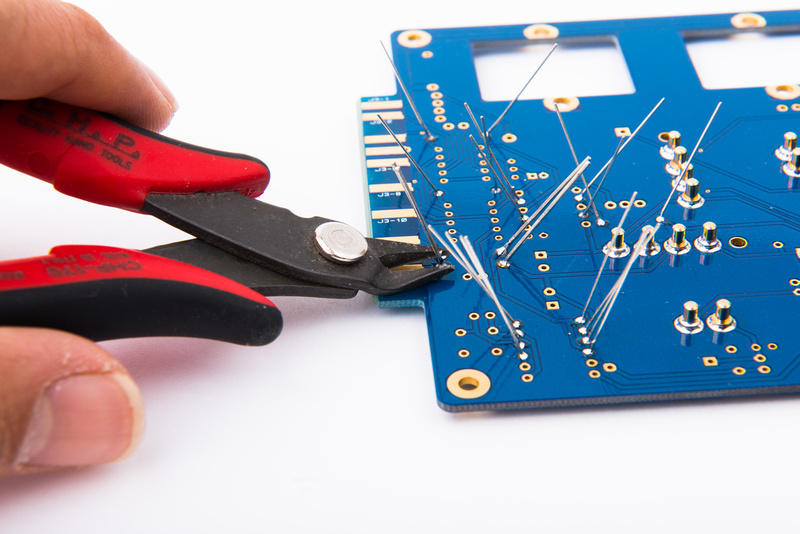

After soldering, trim the excess leads close to the PCB.

And, it never hurts to clean the board a bit while we have full access.

Next, populate the resistors in similar fashion. It does not hurt to verify resistor values with a multimeter before bending and inserting them into the board.

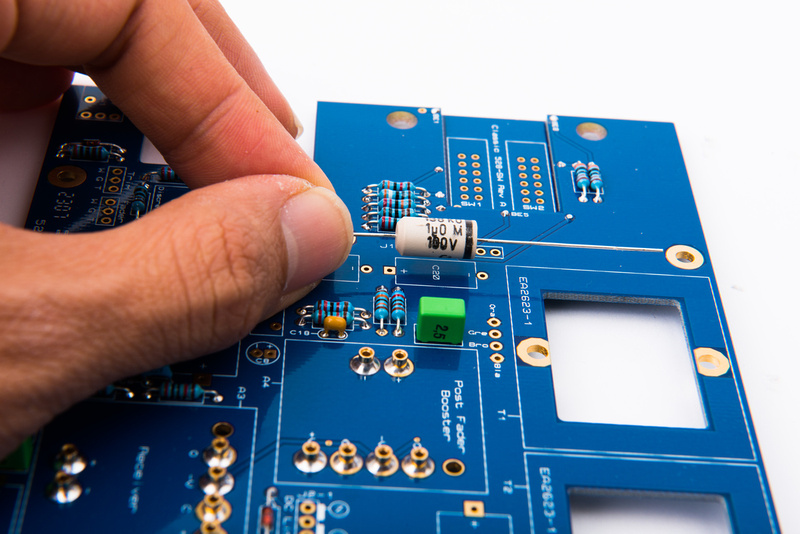

Next, locate and identify the capacitors and relays for the main PCB.

Pay attention to the polarity of the electrolytic capacitors. The side with the line corresponds to the "-" marking on the PCB. The end with the longer lead should go into the side marked "+".

Some of the axial capacitors also have polarity so watch for the perpendicular line indicating "-" side. We want to avoid smoke and excitement when we power up!

Here, the capacitors are populated.

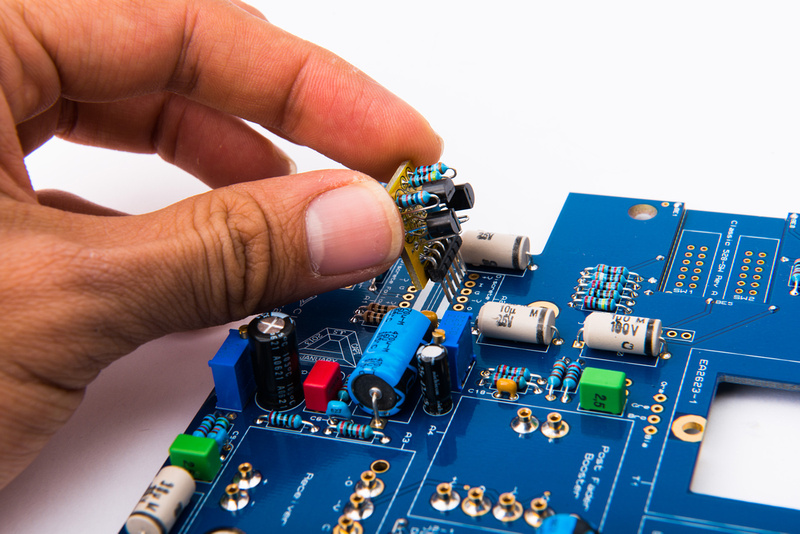

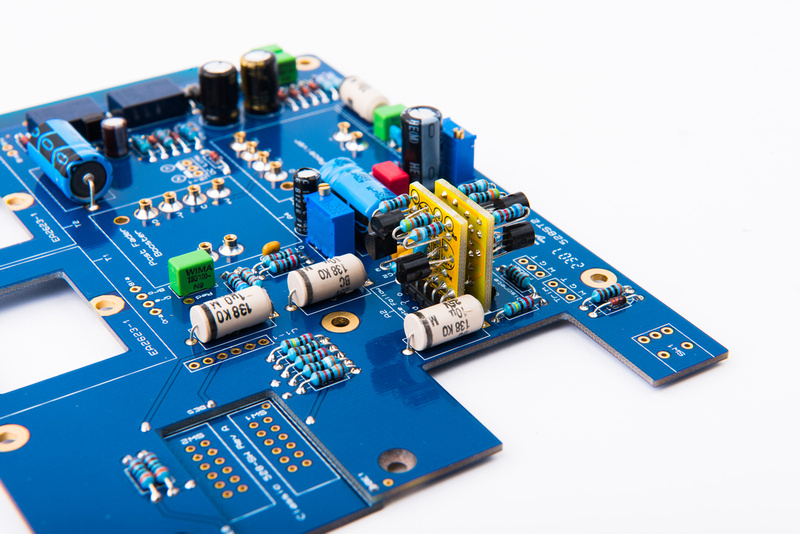

Next, install the previously built discrete follower boards onto the main PCB.