No confusion here. The mixer is for me, and anyone who might be interested in it. I'm not trying to design a commercial product. This is a DIY forum.There seems to be some confusion as to who this mixer is for in the market.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

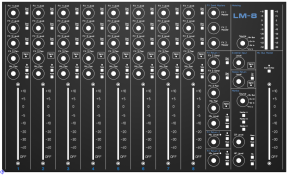

Compact desktop line mixer?

- Thread starter OneRoomStudio

- Start date

Help Support GroupDIY Audio Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Happy to. I have attached both a FPD (what I used to make it) and a DXF version using your attachment trick. Like I said...not 100% set in stone. This was really just a POC. As for the 3D file, the only application I have that can open 3D files is SketchUp, which should be able to import DWG, DXF, or STL.[Would you be willing to share the working 3D file you have?] -- I'll share you mine, if you will share with me yours!!! Is it FPD?

Which CAD-file format would you like to have? -- STP? IGS? FPD? SLDPRT? X_T? Let me know, OK???

/

Attachments

Last edited:

MidnightArrakis

Well-known member

[should be able to import DWG, DXF, or STL] -- I can do -- 3D STL -- but, not right away right now. I gotta take-off and run some errands before it becomes too late to do so here.Happy to. I have attached both a FPD (what I used to make it) and a DXF version using your attachment trick. Like I said...100% set in stone. This was really just a POC. As for the 3D file, the only application I have that can open 3D files is SketchUp, which should be able to import DWG, DXF, or STL.

View attachment 144947

/

MidnightArrakis

Well-known member

[I have attached both a FPD (what I used to make it) and a DXF version] -- I have 3 immediate questions for you:Happy to. I have attached both a FPD (what I used to make it) and a DXF version using your attachment trick. Like I said...not 100% set in stone. This was really just a POC. As for the 3D file, the only application I have that can open 3D files is SketchUp, which should be able to import DWG, DXF, or STL.

View attachment 144947

- Which "unit-of-measurement" did you use? Imperial (inch)? Or, metric?

- How thick is this panel supposed to be? I am measuring 0.079" or 2mm, neither of which is a standard thickness.

- What material is this panel supposed to be made from?

>> NOTE: Galvanneal is a rather "unknown" type of sheet-metal, but it is widely used in both the computer and medical electronics industries for their enclosures. Although a tad-bit more expensive than the run-of-the-mill aluminum, it does have some positive attributes, one of which is that it has a really nice finish to it. Just sayin'.....

>> SORRY!!! -- In my world, I always have to deal with and work in -- ABSOLUTES -- and no "if's, and's or but's" as Frank may or probably does at his FPD company.

/

The units are mm. It's set to 2mm because FPD doesn't allow the selection of 1.5mm (the thickness of the original Takachi panel) at this size.[I have attached both a FPD (what I used to make it) and a DXF version] -- I have 3 immediate questions for you:

Based upon the sheet-metal chart shown below, your panel thickness of 0.079" only comes close in either the Galvanneal or Stainless Steel metals or in the standard Aluminum 5052-H32 at 0.081" thick. Let me know, OK???

- Which "unit-of-measurement" did you use? Imperial (inch)? Or, metric?

- How thick is this panel supposed to be? I am measuring 0.079" or 2mm, neither of which is a standard thickness.

- What material is this panel supposed to be made from?

>> NOTE: Galvanneal is a rather "unknown" type of sheet-metal, but it is widely used in both the computer and medical electronics industries for their enclosures. Although a tad-bit more expensive than the run-of-the-mill aluminum, it does have some positive attributes, one of which is that it has a really nice finish to it. Just sayin'.....

View attachment 144950

>> SORRY!!! -- In my world, I always have to deal with and work in -- ABSOLUTES -- and no "if's, and's or but's" as Frank may or probably does at his FPD company.

/

The original panel is spec'd at "A1100P" anodized aluminum, but FPD uses EN AW 5005 H24/34 [Al Mg1 (B)], which they have available in 2mm thickness.

Last edited:

Additional information that might be helpful:

For the channel PCBs, I used pots with the centerline of the shaft sitting 12.5mm from the surface of the PCB, and push button switches with the centerline of the actuator sitting 5mm above the PCB. I assumed a 1.6mm thick PCB (standard thickness), and I have the pots and switches mounted on the opposite sides of the PCBs - so the centerline of the pots should be 19.1mm away from the centerline of the switches (12.5 + 1.6 +5).

I used rotary switches with shafts that sit 6.5mm above the surface of the PCB, so the monitor select and meter select switch locations in the master section reflect that. Faders will mount to small PCBs that sit beneath them. The only board I haven't quite figured out is the one that will hold the mix bus insert switch and LED bar graphs.

For the channel PCBs, I used pots with the centerline of the shaft sitting 12.5mm from the surface of the PCB, and push button switches with the centerline of the actuator sitting 5mm above the PCB. I assumed a 1.6mm thick PCB (standard thickness), and I have the pots and switches mounted on the opposite sides of the PCBs - so the centerline of the pots should be 19.1mm away from the centerline of the switches (12.5 + 1.6 +5).

I used rotary switches with shafts that sit 6.5mm above the surface of the PCB, so the monitor select and meter select switch locations in the master section reflect that. Faders will mount to small PCBs that sit beneath them. The only board I haven't quite figured out is the one that will hold the mix bus insert switch and LED bar graphs.

studio1117 RSS

Member

- Joined

- Dec 21, 2020

- Messages

- 5

Well it's obvious from design choices you're making I suppose that this isn't meant for mass consumption. I think there is a missed opportunity here for this to appeal to a larger audience.No confusion here. The mixer is for me, and anyone who might be interested in it. I'm not trying to design a commercial product. This is a DIY forum.

The whole point of this place is DIY. If there are elements of this that you like, you can take them and use them to build something of your own that meets your needs. If you’re waiting for someone here to design a product for you, you’re in the wrong place.Well it's obvious from design choices you're making I suppose that this isn't meant for mass consumption. I think there is a missed opportunity here for this to appeal to a larger audience.

studio1117 RSS

Member

- Joined

- Dec 21, 2020

- Messages

- 5

I found your dream mixer.... the Alesis 1622. It's plastic-y, old and basic looking and there are a ton of your beloved 1/4" input and output jacks on the back. I'm not waiting on anybody to design me anything. I'm trying to help you not waste time missing out on a lot of simple features.The whole point of this place is DIY. If there are elements of this that you like, you can take them and use them to build something of your own that meets your needs. If you’re waiting for someone here to design a product for you, you’re in the wrong place.

I've watched as you are unwilling to compromise on the most basic and obvious design features. You want LED meters and 990/transformer outputs yet have no ability to even make it a simple summing mixer.

Your ideas and plans are archaic at best and time wasting at the most basic. You and you alone would appreciate the simple, limited features of this design. You want to draw with crayons, have at it. Good luck maintaining interest with your Kinder Konsole

I don’t know why you’re getting so aggressive. Summing had always been a part of the design. If you look at any version of the block diagram I’ve shared, it shows active summing using a pair of 990’s, followed by a second pair of 990’s to drive the output transformers.

You only have 5 posts on this forum, and all but one seem to be in this thread giving me a hard time. I’ve been active in this forum for over 20 years and I’m just tossing around some ideas with others about a mixer I’d like to build.

You only have 5 posts on this forum, and all but one seem to be in this thread giving me a hard time. I’ve been active in this forum for over 20 years and I’m just tossing around some ideas with others about a mixer I’d like to build.

Well it's obvious from design choices you're making I suppose that this isn't meant for mass consumption. I think there is a missed opportunity here for this to appeal to a larger audience.

Forum Rule #4. You will find that the members of this community are courteous and respectful of each other, so please reciprocate those gestures. Leave the flame-war mentality at another forum.I found your dream mixer.... the Alesis 1622. It's plastic-y, old and basic looking and there are a ton of your beloved 1/4" input and output jacks on the back. I'm not waiting on anybody to design me anything. I'm trying to help you not waste time missing out on a lot of simple features.

I've watched as you are unwilling to compromise on the most basic and obvious design features. You want LED meters and 990/transformer outputs yet have no ability to even make it a simple summing mixer.

Your ideas and plans are archaic at best and time wasting at the most basic. You and you alone would appreciate the simple, limited features of this design. You want to draw with crayons, have at it. Good luck maintaining interest with your Kinder Konsole

Be nicer...

JR

MidnightArrakis

Well-known member

[The units are mm / FPD doesn't allow the selection of 1.5mm / The original panel is spec'd at "A1100P", but FPD uses EN AW 5005] -- It appears to me as though you are allowing a software program to dictate to you -- HOW -- you are going to design a sheet-metal panel, instead of -- YOU -- telling the software program -- HOW -- you want your sheet-metal piece TO BE DESIGNED!!! However and on the other hand.....you have also made it abundantly clear that this project is -- YOUR BABY -- so if you want to be told under what criteria and parameters that you are allowed to design by and under.....THAT'S YOUR CALL!!!The units are mm. It's set to 2mm because FPD doesn't allow the selection of 1.5mm (the thickness of the original Takachi panel) at this size.

The original panel is spec'd at "A1100P" anodized aluminum, but FPD uses EN AW 5005 H24/34 [Al Mg1 (B)], which they have available in 2mm thickness.

So, tell me:

- How thick do you -- REALLY WANT -- your panel to be?

- Of what material -- DO YOU REALLY WANT -- your panel to be made from? Typically, here in the U.S., it will be either:

- Aluminum - 5052-H36

- Aluminum - 6061-T6

- Cold-Rolled Steel

- Galvanneal

Instead of using "Front Panel Designer", maybe one of these other bracket/chassis/panel design programs may be better for you:

- https://www.protocasedesigner.com/download/

- https://www.rcicustom.com/panel-design-tool/ -- The CAD-design program that this company offers is specifically geared towards the "Professional Audio & Video" industries. Their libraries are filled with XLR-cutouts, 1/4" jack and plug cutouts, AC-mains connector cutouts and so much more!!! And.....they also just happen to be about 30-minutes down the highway from where I live!!!

/

Last edited:

Rowboat

Well-known member

Hi OPWhy aren't there more options out there for high-quality compact desktop line level mixers? It seems like these would be popular for hybrid ITB/OTB mixing. I'd love something with around 12 channels (or 8 channels and FX returns), and simple controls (maybe trim, HPF, pan, auxes, solo, mute, fader). The closest I've seen is the Speck VF10M, which only has solo, mute, and fader, and costs $2800!

There are plenty of cheap prosumer mixers out there from Yamaha, Mackie, A&H, etc...but those all have far more features than I want, and implement them cheaply (more things to fail, more cheap parts in the signal path, etc). Something like the SSL SiX gets close, but costs too much for what it is.

I'd love something like a modern interpretation of the Studer/Revox C279 for around $1,000-$1,500.

Am I alone here? Is everyone else happy just mixing in the box or out on a huge console? Are there other options I'm overlooking?

No, you're definitely not alone! I've been tearing my hair out for such a mixer.

What I'd like would be equipped with at least eight channels, four busses plus l/r stereo buss/ master outs.

Each channel with ¼ jack inputs switchable from line level to instrument impedance, pannable, fx send/return; and a meter bridge. It'd probably look like an old Tascam mixer.

No onboard effects. No channel preamps. No parametric equalization. Baxandall or none.

I'd like it to mix guitar signal pre-processed with multiple stereo effect units (i.e. parallel), and to output enough rms voltage to drive an old Crown DC300-A I have (or any other 2-chan power amp).

Fx send/return would allow me to utilize an old Lexicon's reverb algos, if one turned up.

Last edited:

ruffrecords

Well-known member

Just to put this into context, FPD is a free program provided by Schaeffer specifically for designing front panels FOR THEM TO MAKE. In fact, if you read the small print in the licence documentation, you are specifically forbidden to use the files to get anyone else to make your panels (although many panel manufacturers will accept fpd files). Given that context, the material restrictions are not surprising.[The units are mm / FPD doesn't allow the selection of 1.5mm / The original panel is spec'd at "A1100P", but FPD uses EN AW 5005] -- It appears to me as though you are allowing a software program to dictate to you -- HOW -- you are going to design a sheet-metal panel, instead of -- YOU -- telling the software program -- HOW -- you want your sheet-metal piece TO BE DESIGNED!!! However and on the other hand.....you have also made it abundantly clear that this project is -- YOUR BABY -- so if you want to be told under what criteria and parameters that you are allowed to design by and under.....THAT'S YOUR CALL!!!

The real point of my reply is that FPD is a very easy program to use, a million miles better than any other mechanical drawing package I have come across which is perhaps why so many DIYers use it. The restriction in material type/thickness is a small price to pay.

Cheers

Ian

MidnightArrakis

Well-known member

[FPD is a free program provided by Schaeffer specifically for designing front panels FOR THEM TO MAKE] -- See below:Just to put this into context, FPD is a free program provided by Schaeffer specifically for designing front panels FOR THEM TO MAKE. In fact, if you read the small print in the licence documentation, you are specifically forbidden to use the files to get anyone else to make your panels (although many panel manufacturers will accept fpd files). Given that context, the material restrictions are not surprising.

The real point of my reply is that FPD is a very easy program to use, a million miles better than any other mechanical drawing package I have come across which is perhaps why so many DIYers use it. The restriction in material type/thickness is a small price to pay.

- I am well-aware that the FPD program is free.

- Does this mean that the members on this forum who use this "Frank" guy for making their panels are all in violation of the FPD license agreement? Or, does "Frank" work for SCHAEFFER?

- It then seems to me by simply using the FPD program to design your panels, that then basically limits the user to a "Single-Source" vendor. While I do recognize that "my designing world" is rather radically different than the members of this forum, my designing anything that becomes a "Single-Source Vendor" item is essentially a -- NO - NO!!! -- for me to do.

- And, I also recognize and understand the required "easy-to-use" feature of FPD, as most everyone else on this forum isn't a full-time "Electronics Equipment Mechanical Designer" as I am. I get it. But, still.....I personally wouldn't use a program that dictates to me -- HOW -- I am able to design anything/something. But.....that's just me.

MidnightArrakis

Well-known member

[the Takachi CF45-28] -- Here is what your FPD front-panel looks like within the TAKACHI CF45-28 enclosure!!! COOL, HUH???Sorry, I meant the one we’ve been talking about most recently - the Takachi CF45-28

I apologize about there not being any of your graphics and text being included on this panel. There isn't any corresponding "sheet-metal" feature for them to be converted into and displayed as such within my SolidWorks program. SORRY ABOUT THAT!!!

>> I am more than certain that @ruffrecords will also be interested in seeing this as well.

/

Last edited:

Rowboat

Well-known member

My golly that's enticing[the Takachi CF45-28] -- Here is what your FPD front-panel looks like within the TAHACHI CF45-28 enclosure!!! COOL, HUH???

I apologize about there not being any of your graphics and text being included on this panel. There isn't any corresponding "sheet-metal" feature for them to be converted into and displayed as such within my SolidWorks program. SORRY ABOUT THAT!!!

View attachment 145062

/

ruffrecords

Well-known member

One interesting aspect of Schaeffer's front panel service is that they can use customer provided material so, rather than buy a complete enclosure like the Takachi and have to replace some of its panels with custom ones you can send the blank panels to Schaeffer for them to use on your design.[the Takachi CF45-28] -- Here is what your FPD front-panel looks like within the TAKACHI CF45-28 enclosure!!! COOL, HUH???

I apologize about there not being any of your graphics and text being included on this panel. There isn't any corresponding "sheet-metal" feature for them to be converted into and displayed as such within my SolidWorks program. SORRY ABOUT THAT!!!

Cheers

Ian

ruffrecords

Well-known member

Additional information that might be helpful:

For the channel PCBs, I used pots with the centerline of the shaft sitting 12.5mm from the surface of the PCB, and push button switches with the centerline of the actuator sitting 5mm above the PCB. I assumed a 1.6mm thick PCB (standard thickness), and I have the pots and switches mounted on the opposite sides of the PCBs - so the centerline of the pots should be 19.1mm away from the centerline of the switches (12.5 + 1.6 +5).

Looking at your front panel fpd file it seems the pots and switches are the same positions on the PCB, just on opposite sides. I have only done this once before in a design and I swore I would never do it again. It makes the build impossible to debug or repair. I know you are kind of forced into it due to the limited space but it can be a very annoying source of problems ----- unless you managed to source a switch with its pins far enough back that they do not interfere with the ones of the pot?

I am always on the lookout for rotary switches. Which ones did you choose?I used rotary switches with shafts that sit 6.5mm above the surface of the PCB, so the monitor select and meter select switch locations in the master section reflect that. Faders will mount to small PCBs that sit beneath them. The only board I haven't quite figured out is the one that will hold the mix bus insert switch and LED bar graphs.

Cheers

Ian

Yes, they are directly on opposite sides of the board. I didn’t go so far as to check if the footprints overlap (yet). They might need to be offset. The layout was all preliminary - like I said before, just a POC. I have done this with other project before, and while it is a pain, it can be done…as long as you solder the correct side first!Looking at your front panel fpd file it seems the pots and switches are the same positions on the PCB, just on opposite sides. I have only done this once before in a design and I swore I would never do it again. It makes the build impossible to debug or repair. I know you are kind of forced into it due to the limited space but it can be a very annoying source of problems ----- unless you managed to source a switch with its pins far enough back that they do not interfere with the ones of the pot?

I am always on the lookout for rotary switches. Which ones did you choose?

Cheers

Ian

These are the rotary switches I spec’d. I used them once before and they seemed fine: https://www.mouser.com/ProductDetai...F0B-C7-N-0027?qs=8%2Br4Hz5Xir/fy%2Bqxa0GVpg==

Similar threads

- Replies

- 82

- Views

- 17K

- Replies

- 4

- Views

- 2K

- Replies

- 12

- Views

- 3K