ruffrecords

Well-known member

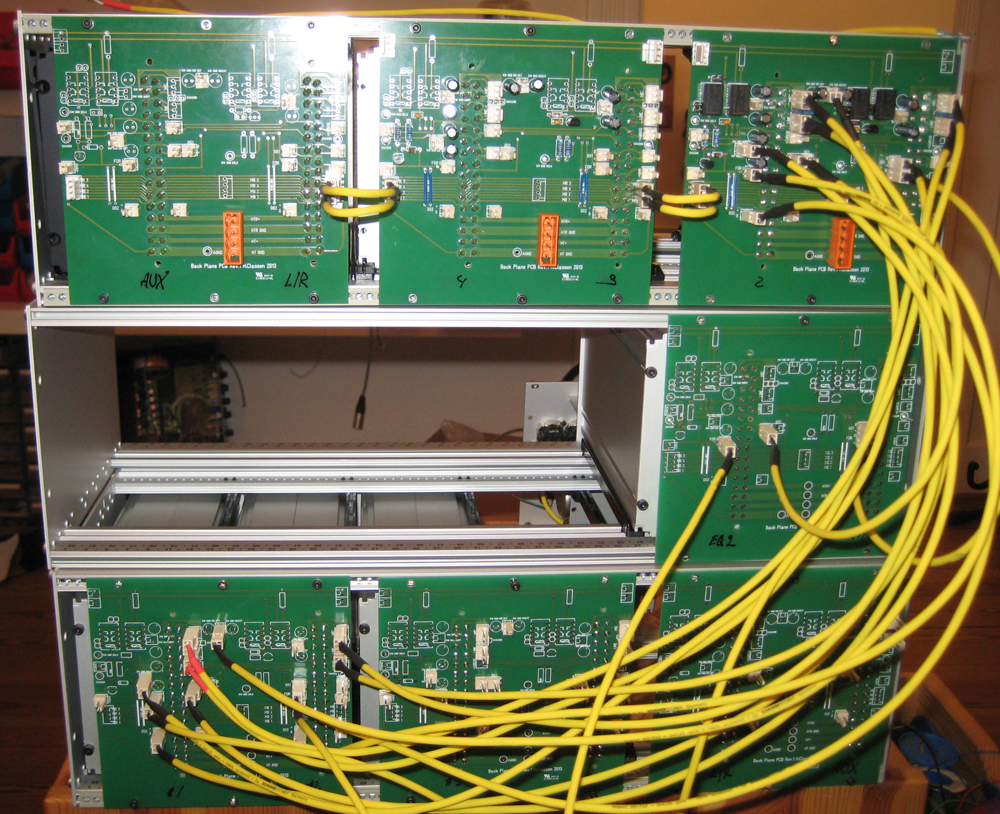

Holger said:ruffrecords said:...

That is a good price for the PCBs. Did you stick to 1.6mm thickness?? I used 2.5mm for mine for some added strength.

...

1.6mm thickness. Another advantage of the relatively small PCB size.

I just checked the on line price of a PCB 128.4mm square with my two regular suppliers and both are more expensive the 9 Euros for 20 off. Where did you get the boards made?

Cheers

Ian