chunger

Well-known member

Matador said:Cool, I'll was thinking of trying this surgery myself. I'm curious to see how much of a difference it makes sonically. How did you end up doing it? Did you bake the entire thing or use a torch?

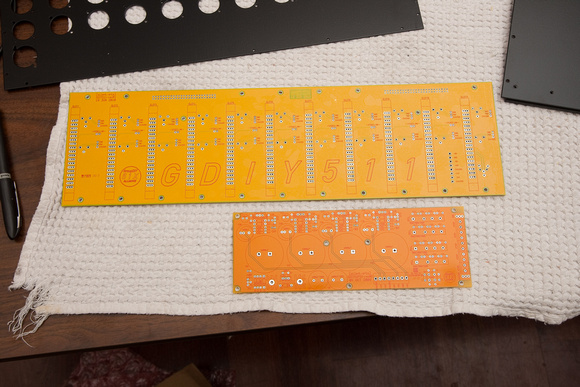

For colors, I always switch to black solder mask with yellow silkscreen for final versions of projects.

No, I didn't use heat. That would probably make everything loosen up including the vertical support bars and I suspect you would end up with a pile of deformed mess. From the bottom of the headbasket, you can observe 2 prominent "blogs" of solder paste holding the vertical bars and 3 layers of mesh together. One side has the end-joint of all mesh layers. Starting there, I simply cut around the solder paste blob with cutters on the inner layer of mesh. After a little cutting, I was able to pry the inner layer free at the corner with a fine screwdriver and continue cutting around the solder paste blob freeing the inner mesh layer. Then, I progressed to pliers and just kept prying/cutting along the perimeter. Some rather vigorous pulling was required.

The entire process took about 10 minutes and at some point, when I pulled, the 2nd mesh layer came with, so I just went with it. Note: This method only removes mesh layers on the sides of the headbasket and not on the top section. I couldn't squeeze my cutters all the way down into the top portion and have any sort of control.

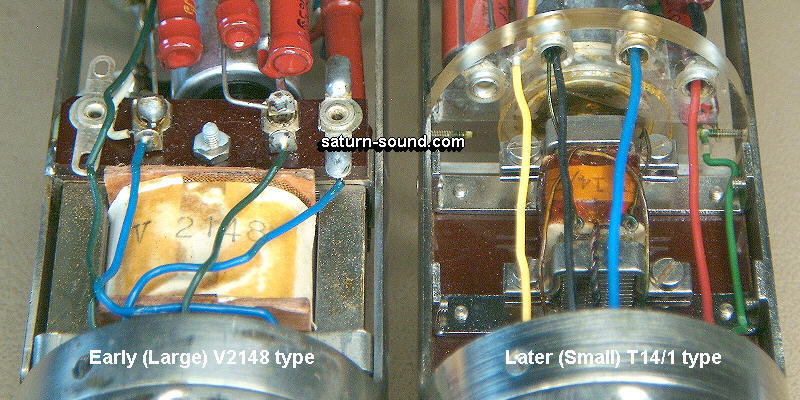

This is a VERY tight meshing setup. I suspect the stock setup was so sibilant they used tight mesh and lots of layers to try and contain it.

Regarding the solder mask color. . . please don't to black. I know, it's the flavor of the month and many new CAPI as well as IJ Research kits currently use it. I am well familiar with shooting these. No disrespect for these brilliant designers and their kits, but it is HARD to shoot black (matte and glossy). Every little spec of dust, flux, and fingerprint shows up and it generally pisses me off probably because I have obsessive compulsive disorder. Also, the black is, well, dark. . . makes it a little more difficult to light all the parts. So far, my happiest shoot (visually) has been the VC528 with it's dark blue, yellow, and red pcb's contrasted with the slew of red WIMA caps. Assuming our final C12 cap will be yellow like the prototype, I vote dark blue (or stay green) if we go muted to go complimentary color to the cap, but I'm partial to yellow on the PCB. Maybe I'm nostalgic for my first DIY project.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)