IT'S ALIVE!

So I finally got everything buttoned up. First order of business was to correct the power supply voltages. Since I switched the design from half-wave to full-wave bridge, the B+ voltage was way too high. I increased the RC filter resistors from 5K to 100K each. I also increased the last filter resistor from 27K up to 33K. This brought the loaded B+ from 250V+ down to 120V. A 50K pot in the last filter spot would give enough adjustment range with multiple tube types so that seems like a good value.

To begin, I dialed down the bias voltage until it read -2V on the meter. Then I connected the cables to the mike sans the capsule so that I could read voltages from various points:

1) Tube plate voltage: 81V

2) B+ supply at top of 100K plate resistor: 122V

3) Front diaphragm bias voltage: 61V.

So the tube is idling at about 0.4mA, which is consistent with the plate curves for this tube. Much like when biasing a JFET, biasing the tube is a trade-off between gain and input signal swing. I don't have a good idea of the output voltage/sensitivity of Tim's C12 capsule, so I picked a rough starting point of half of the bias range (e.g. -1V).

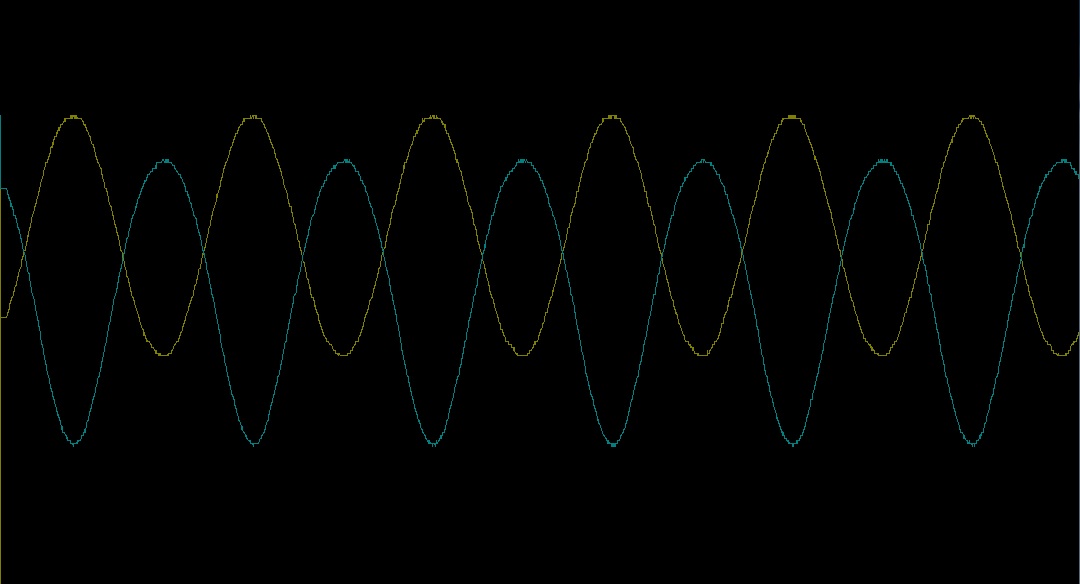

I then connected my signal generator between ground and the front backplate connection, which will inject a signal just prior to the 1000pF coupling cap leading into the tube grid. I set my amplitude to be 500mV peak-to-peak, set my scope probes to AC coupling, then placed another probe right at the tube plate (just prior to the output coupling cap). Here's what I see (I apologize for the unlabeled chart: I took scope shots in the wrong format):

The yellow trace is the input, the blue the output of the plate. You can't tell because it's not labeled, but the output signal swings about 14V peak-to-peak, which means gain is right around 28dB. Maximum signal amplitude before clipping is about 1.2V. Now the transformer will throw away about 20dB of gain so we need to be cognizant of that fact too.

One can get more gain by lowering the negative bias, which causes the quiescent current to increase. So this may need some tweaking after a capsule is installed.

Next steps: I'll install a new 6072A tube, make sure the voltages are still good, and then reinstall the stock Alctron capsule and make a few test recordings. Assuming everything measures fine, I'll get Tim's capsule in there and we're ready for some studio time!

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)