buildafriend

Well-known member

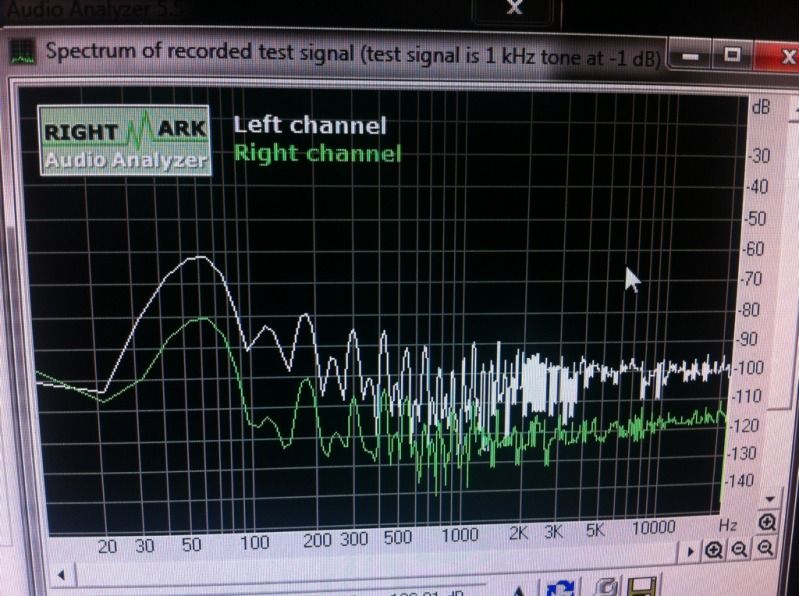

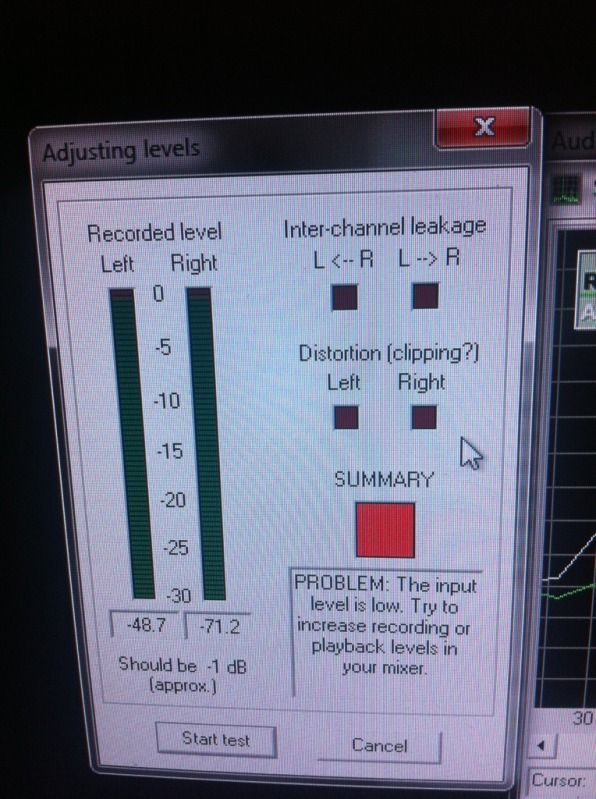

There's a band in pre-pro right now, right behind me. I can check in a few min. If I remember right the hum starts as the tubes heat up. It was not instant.

Edit: Yep just tested it. It starts buzzing once the tubes heat up.

Edit: Yep just tested it. It starts buzzing once the tubes heat up.