Older cores had a max Al value that left a lot to be desired.

I am sure the engineer today would use less turns on a higher Al core for a better "Q", or quality factor , which is the henries divided by the DCR.

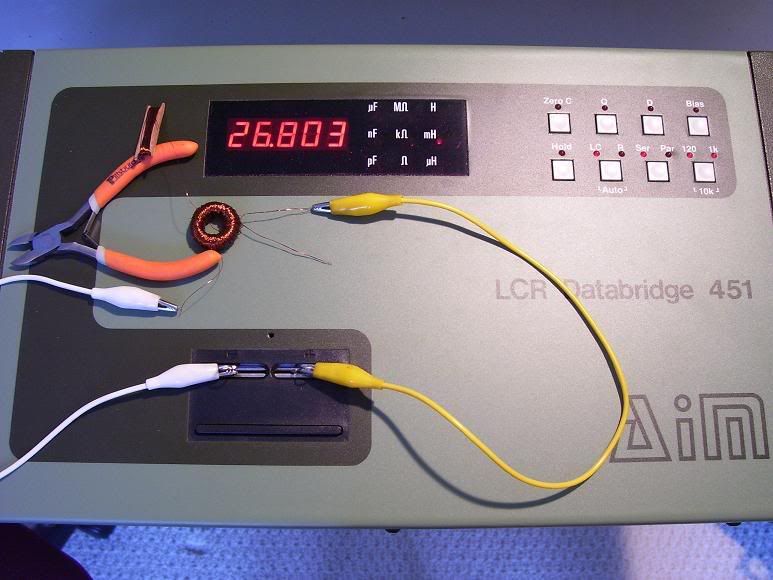

Some meters have a D instead of Q, which is the same thing, only it is 1/Q.

So the higher the Q, the lower your D should be.

If you want old school, then use the original Al.

That way, you keep the turns the same, which means the flux is the same.

When you drop the turns, the flux goes up, because you are working the core harder in order to get more henries for the same price in turns.

So you may get a different sound with a high perm core.

Some of the new powdered cores have amazing Al numbers.

Remember that the thicker wire can mean more leakage C, since the "plates " of the capacitor are equal to the surface area of the wire, 2 pi r.

But you also get more space between turns, which decreases the leakage C.

Which one is worse is determined by bench testing.

You get a better Q because of the lower DCR, the tradeoff is more leakage.

Anything that uses iron is one huge list of off setting factors.

Hey pat, that #34, what did it mic out at?

Thanks!

I am sure the engineer today would use less turns on a higher Al core for a better "Q", or quality factor , which is the henries divided by the DCR.

Some meters have a D instead of Q, which is the same thing, only it is 1/Q.

So the higher the Q, the lower your D should be.

If you want old school, then use the original Al.

That way, you keep the turns the same, which means the flux is the same.

When you drop the turns, the flux goes up, because you are working the core harder in order to get more henries for the same price in turns.

So you may get a different sound with a high perm core.

Some of the new powdered cores have amazing Al numbers.

Remember that the thicker wire can mean more leakage C, since the "plates " of the capacitor are equal to the surface area of the wire, 2 pi r.

But you also get more space between turns, which decreases the leakage C.

Which one is worse is determined by bench testing.

You get a better Q because of the lower DCR, the tradeoff is more leakage.

Anything that uses iron is one huge list of off setting factors.

Hey pat, that #34, what did it mic out at?

Thanks!