Great job Skylar!

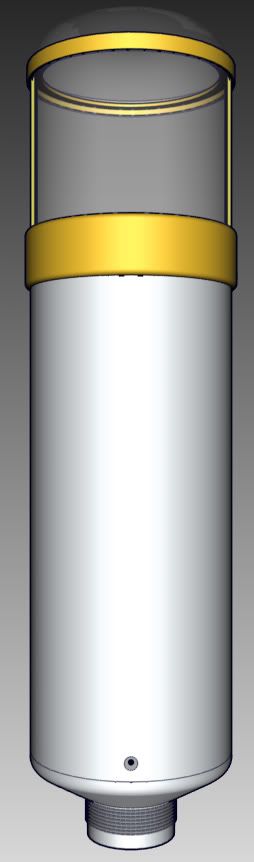

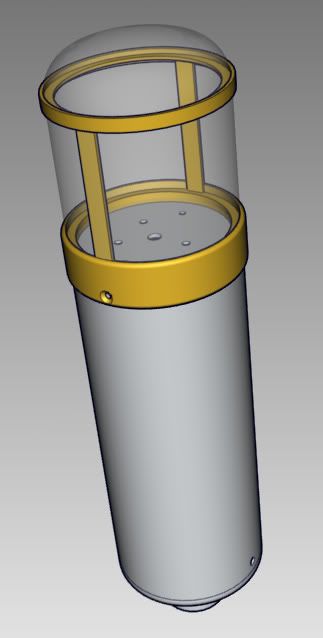

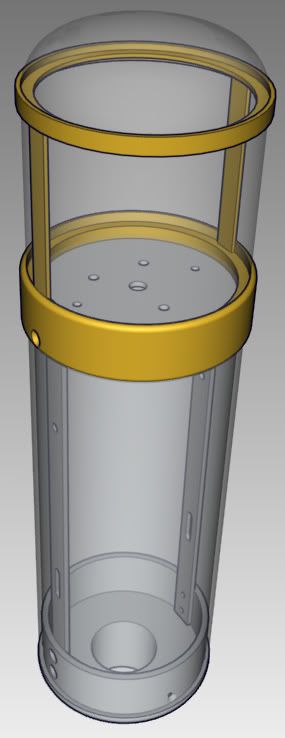

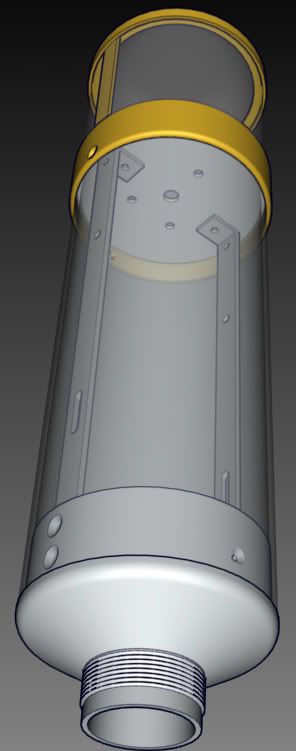

I'm affraid the headbasket design still needs some modification though...

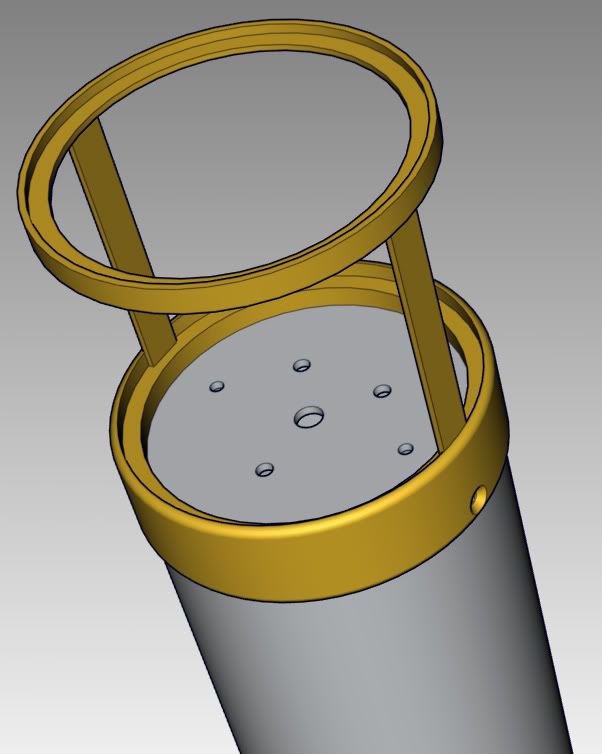

The vertical brass support rails have a thickness, and in your design, they are mounted inside the ring.

So, if the internal ring diameter is, say 60mm., and the thickness of the vertical brass support rails is, say 1mm., that leaves us with a 58mm. useful diameter for the grill, and a 1mm. gap between said grill and ring...

I guess the original vertical brass support rails are thinner than 1mm, but still, they shouldn't cause a gap. Perhaps the solution is to provide some cutout in the ring in order to solder the vertical rails IN the thickness of the ring rather than inside them... I Know, that would mean some milling which cannot be done on the lathe...

Axel

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)