moamps

Well-known member

Makes one wonder just how they made the (what are usually plated) through-hole vias, to connect the top and bottom copper layers...

Maybe that PCB is gold plated and the joints between the top and bottom are made of gold. In any case, it cannot be compared to a beginner's home-made PCB. Soldering joints that look worse are most likely the result of using 0% Pb solder.

I have seen several faulty microphones with a similar malfunction in my working life, from dynamic AKG, Shure, Sennheiser to LDC condenser and ribbon. The reason was always too much G factor. Falling off a stand or during transport, and I don't see much need to be done about it. As for the production itself, one only has to ask whether this microphone justifies the price of 1000Eur with its sound (and name), which is about 6 times less than the Neumann U67.

P.S.

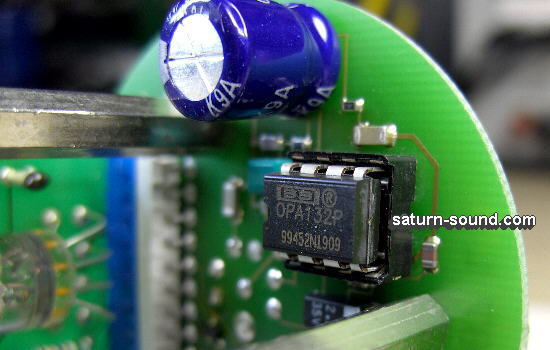

The technology of making PCBs for high-impedance circuitry in condenser microphones requires a different approach than usual. Eg. solder masks, prints, coatings can significantly compromise the insulation between soldering points. Teflon-insulated pins are often used here.