Andriejus

Well-known member

Hi,

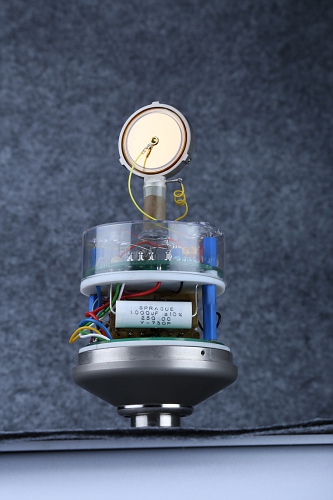

A few more pictures of a bead blasted brass.

Its fat :

:

Few tweaks with photoshop. Changed a saturation of body to black and white.

Silver brazed brass profile to body tube. Took a lot of time to learn how to braze, but results are good enough - very strong and beautifull joints. Although silver brazing rods are expensive, but thats what jewelers use brazing in an open flame method...

Kind regards,

Andrew

A few more pictures of a bead blasted brass.

Its fat

Few tweaks with photoshop. Changed a saturation of body to black and white.

Silver brazed brass profile to body tube. Took a lot of time to learn how to braze, but results are good enough - very strong and beautifull joints. Although silver brazing rods are expensive, but thats what jewelers use brazing in an open flame method...

Kind regards,

Andrew