Hi Alex,

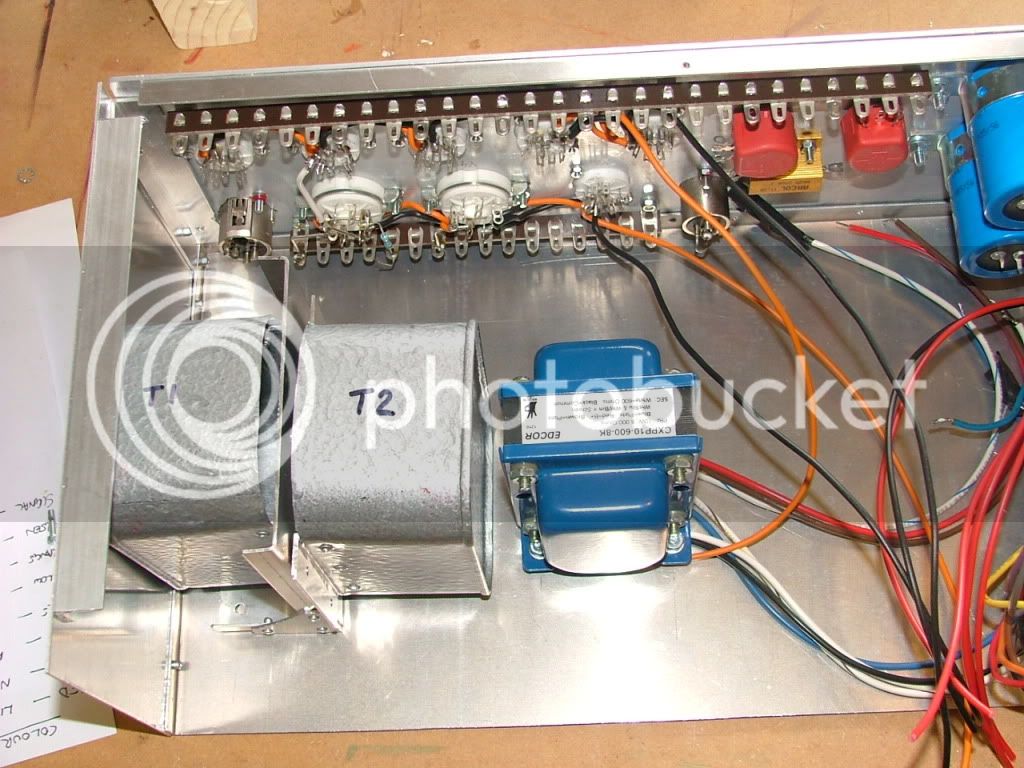

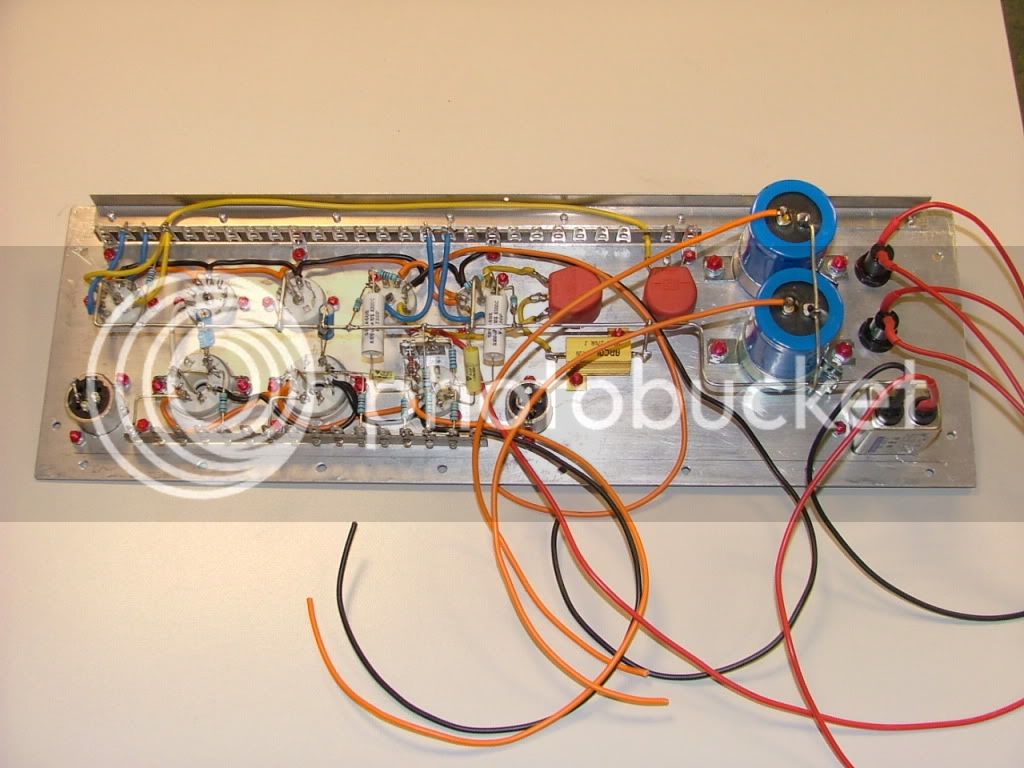

All the levels through the transformers are pretty high, so I was thinking more about shielding the rest of the circuit than hum pick-up in them. You may be right that the shielding could be ineffective but I thought I ought to make the effort as they were inside the chassis, it would be too late or difficult to do later when it was finished.

This bridge arrangement must not have magnetic induction between the transformers or the compression ration will be reduced, so that was the primary reason for shielding them.

We have covered this before, but magnetic shielding is really a misnomer, its much more like a bypass channel than a brick wall. I liked the tins because of the rounded edges, magnetic field propagate from edges, so I'm told.

best

DaveP