now lets look at our AC flux levels,

B=100,000,000 E-RMS/4.44*K*f *N*Ac

E-RMS is the AC voltage across the coil

K is Stacking Factor, it always hovers at around 0.9

f is frequency

N is turns

Ac is core cross section area in square centimeters,

we can make this equation more palatable by dividing 4.44 and 0.9 into the numerator,

100,000,000/(4.44*0.9) = 100,000,000/3.996 =25,025,025, call it 25,500,000, so

B=25,500,000*E-RMS/f N Ac

lets get the cross section next and divide it out too since we are both testing the same size core,

we are looking at a core made from 12 L lams, each lam is 3/8" wide,

so if we multiply 3/8" by our stack height, we wil have the cross section,

i believe we have a 3/4" stack, so 3/8" * 3/4" = 9/32" = 0.28125, convert to cm^2,

0.28125" * 2.54 = 0.714375, call it 0.715 cm^2 and divide it into the numerator,

25,000,000/0.715=34,965,034, call it 35,000,000, so now we have

B=35,000,000 * E-RMS/f * N

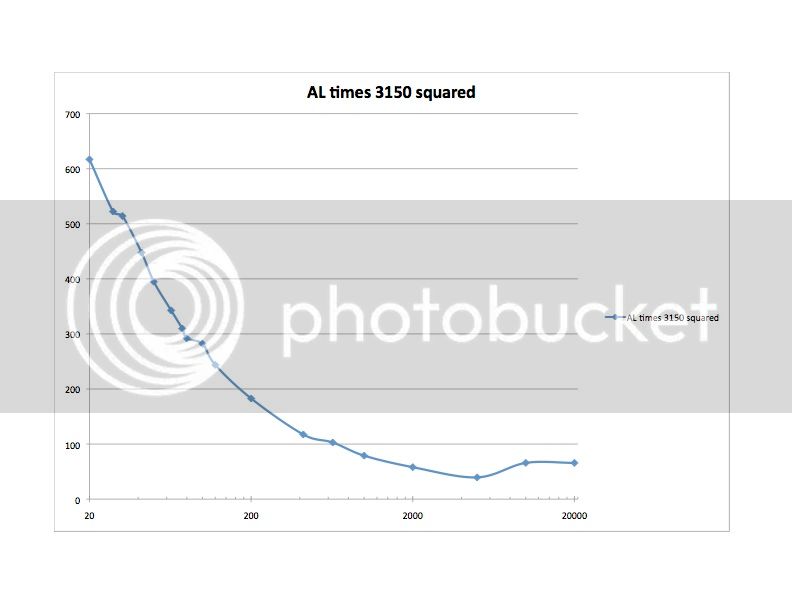

lets assign a frequency for both your test and mine, then we can finally get a grasp of the difference in test conditions,

let f=100 hz, things are pretty stable at this f, not too close to bass cutoff, not too close to core cutoff ( which happens at around 1000 to 2000 hz,)

so if 35,000,000/100 Hz = 350,000, we have

B=350,000 * E-RMS/N

you are using 200 turns, i used about 3,000 turns, you use 1 volt, i use 20 volts, so

B=350,000 * 1 VAC / 200 Turns = 350,000/200 = 1,705 Gauss and

B=350,000 * 20 VAC / 3,000 Turns = 700,000 = 2,330 Gauss,

so it looks like we are in the same ballpark as far as AC flux, if you wanted to get closer to my setup you could use 233/175 = 1.333 times as much voltage or 1.333 volts,

29gaM6 saturates at 18,000 Gauss, Supermalloy at 5,000 Gauss,

so we are not to close to saturation for either material, inductance might come up a bit for both if we increase the voltage level,

now who ever used that 12 L die for making lams could have very easily put a different alloy on the stamping table and knocked out a higher perm core to better suit the application, so if you get higher inductance values, you may have a core made from different material.

which one is correct for the S-217-D? i have no way of telling as i have never had an original on the bench, there might be some data in the Peerless catalog, so i will have a look,

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)