chunger

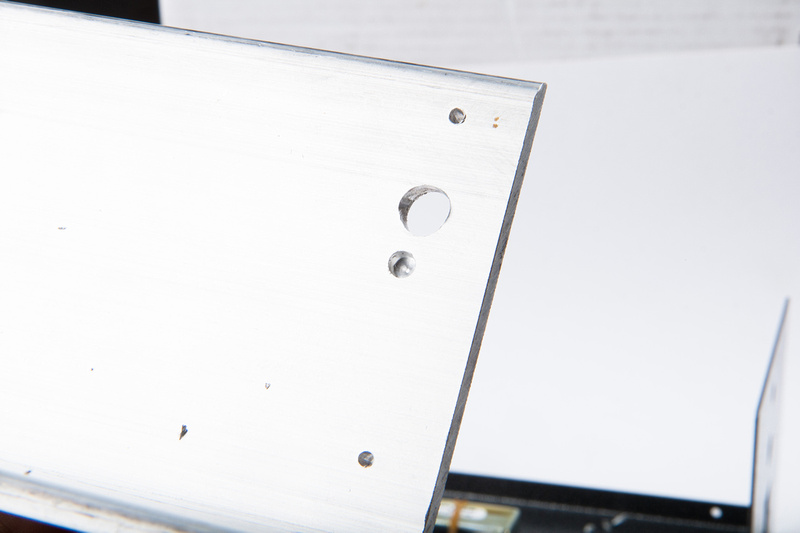

Well-known member

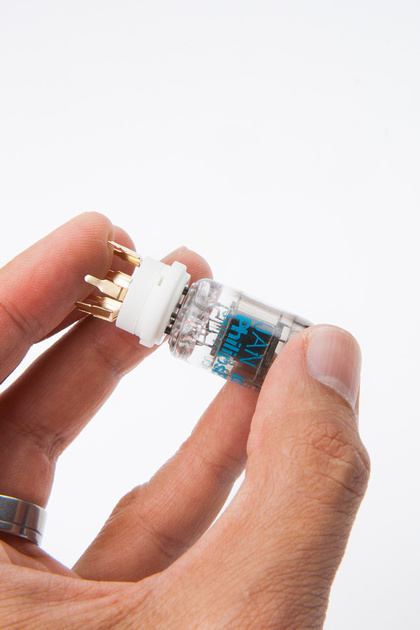

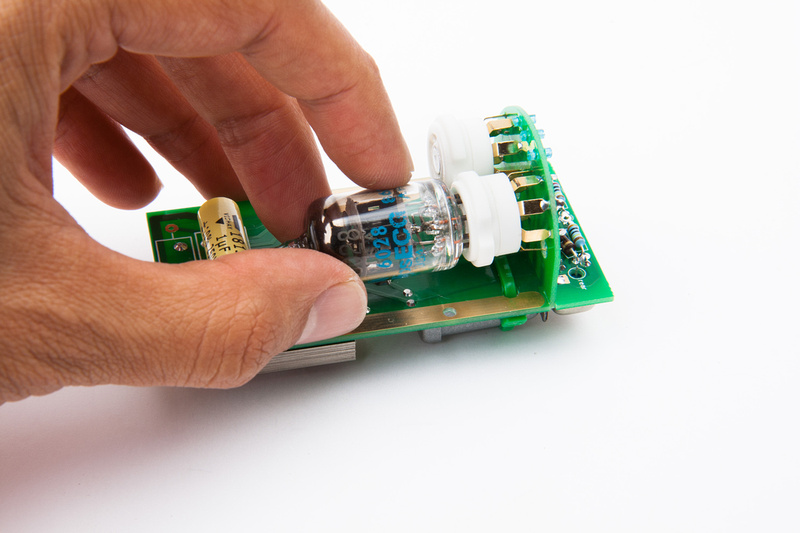

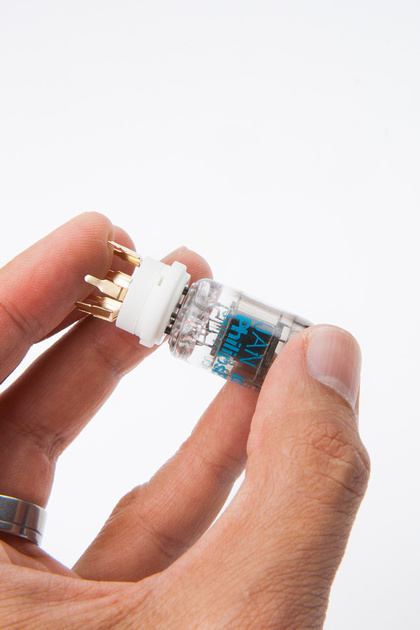

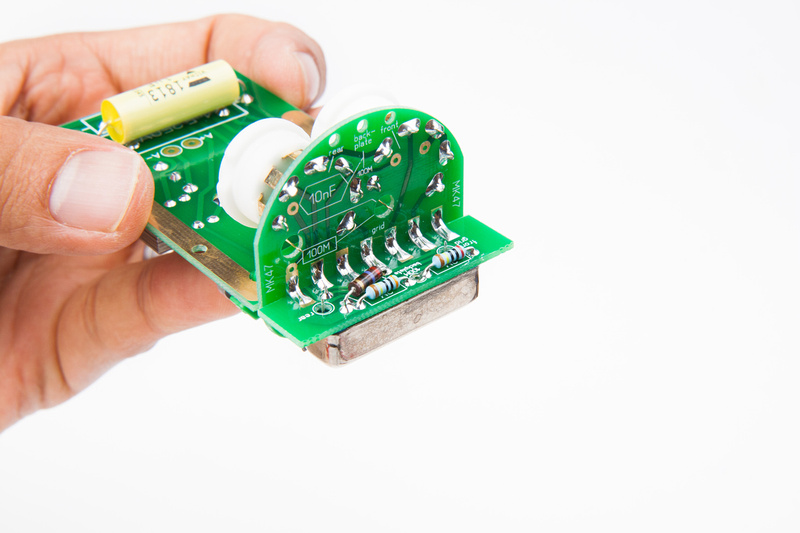

The ceramic tube sockets pins are very stiff when new, so I insert and remove a tube a few times to try and loosen up the sockets before soldering them onto the pcb.

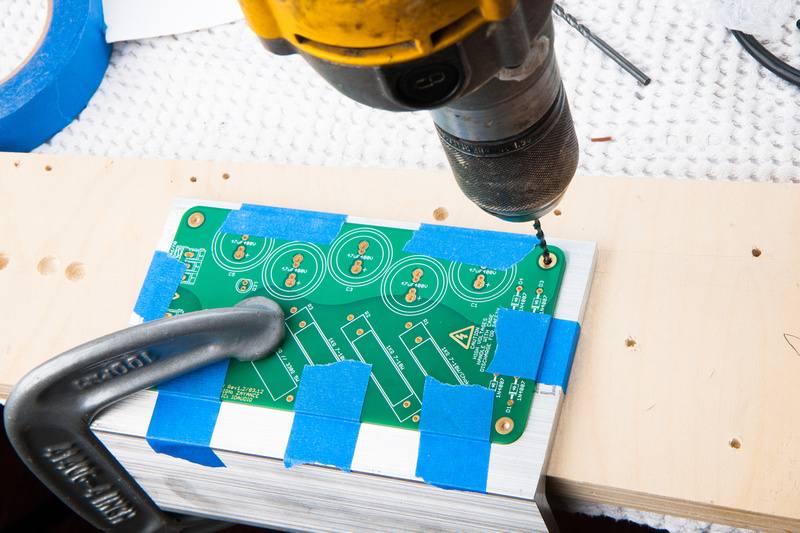

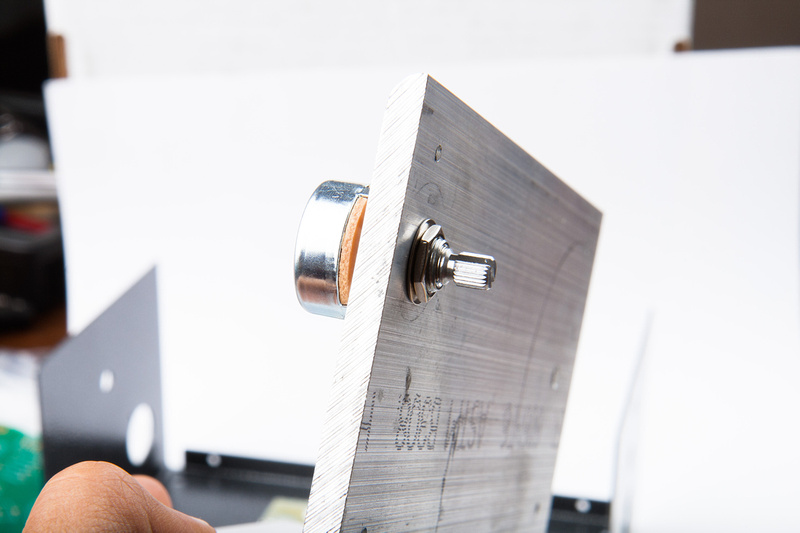

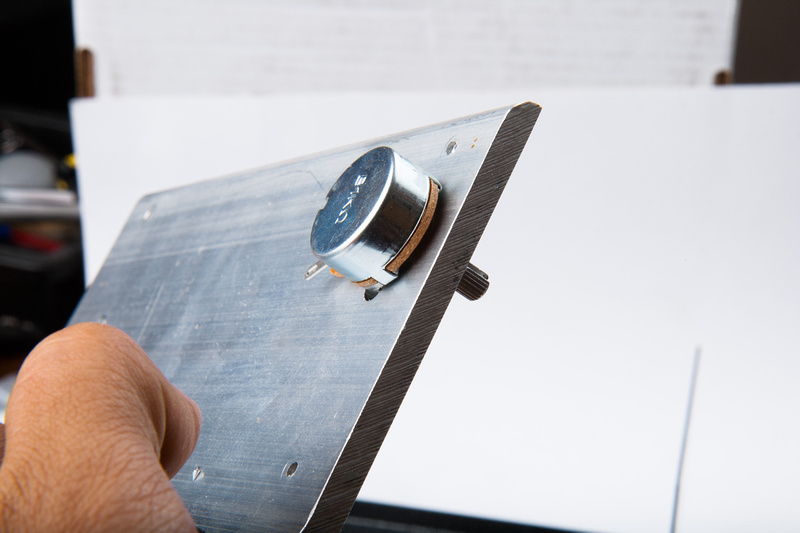

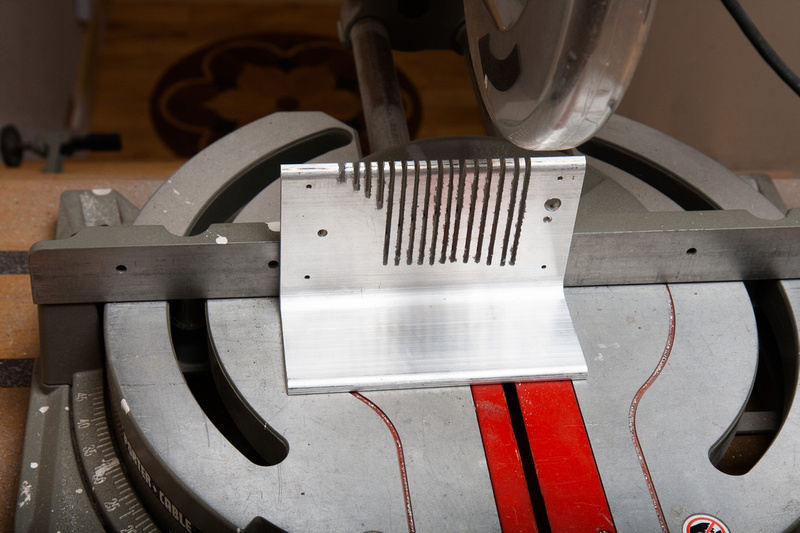

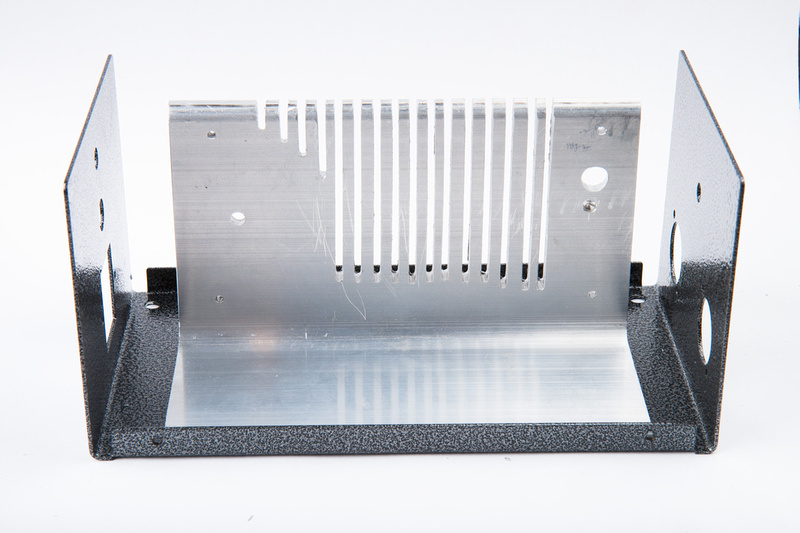

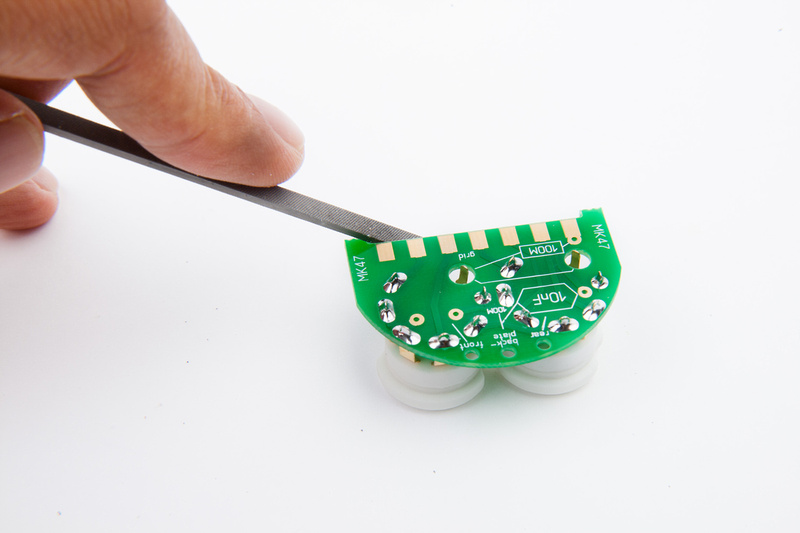

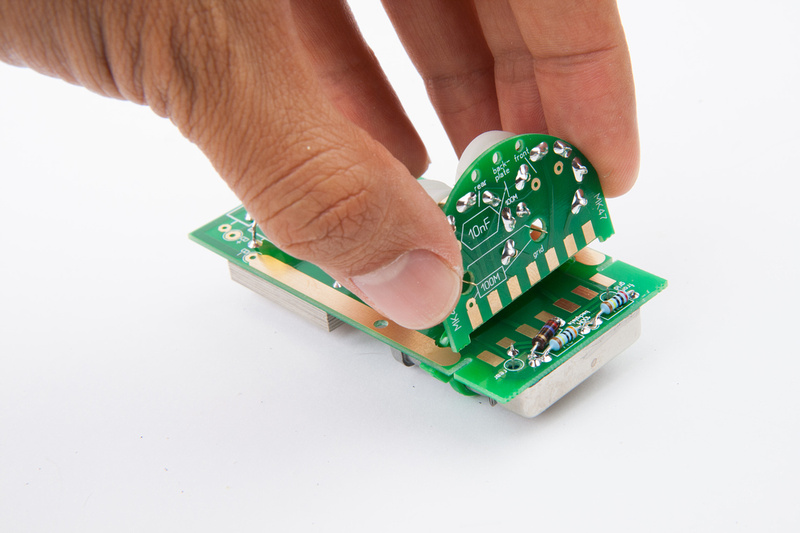

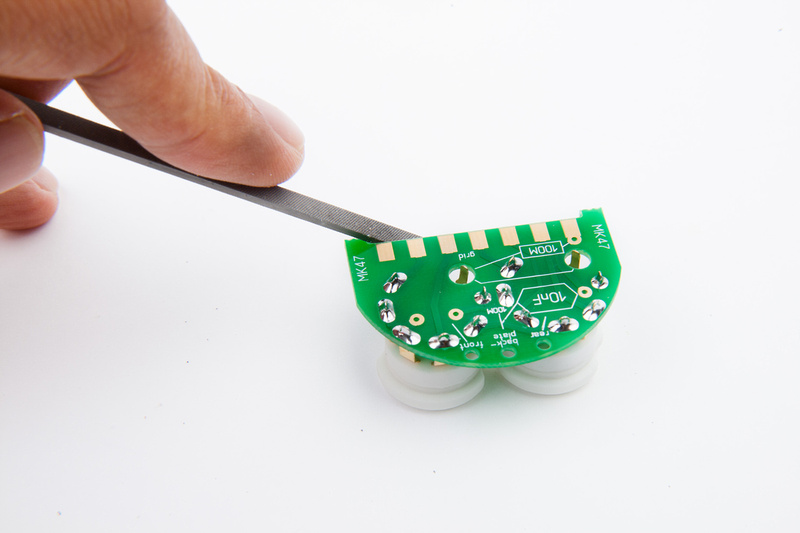

My tube pcb doesn't quite fit into the main pcb, so I round over the inside edges a little bit to make it drop in all the way.

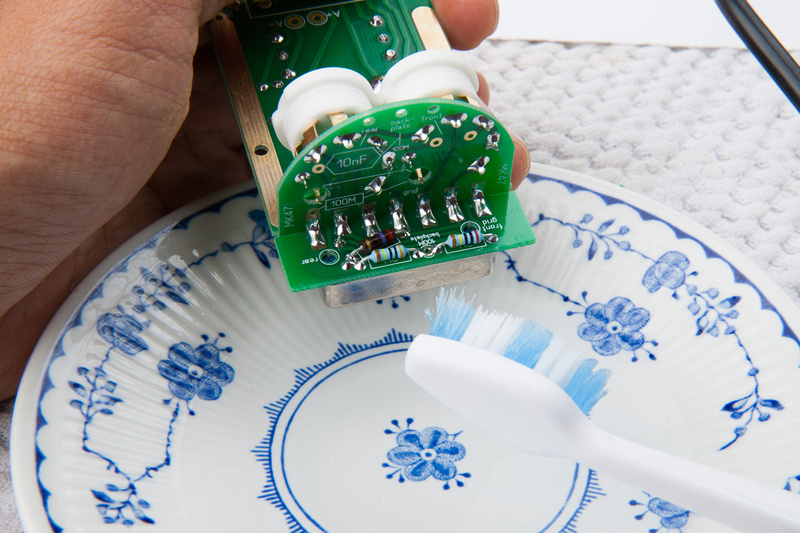

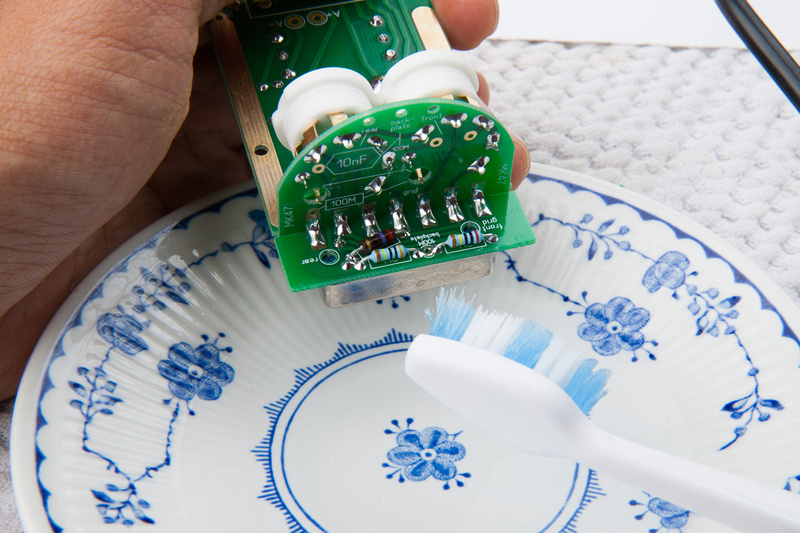

And, of course, I take the opportunity to scrub the tube socket PCB at this time with isopropyl alcohol to clean the flux residue off.

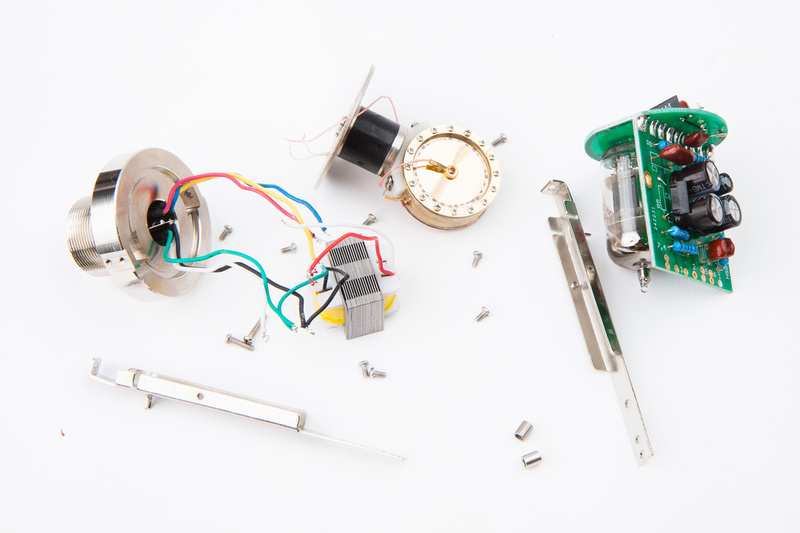

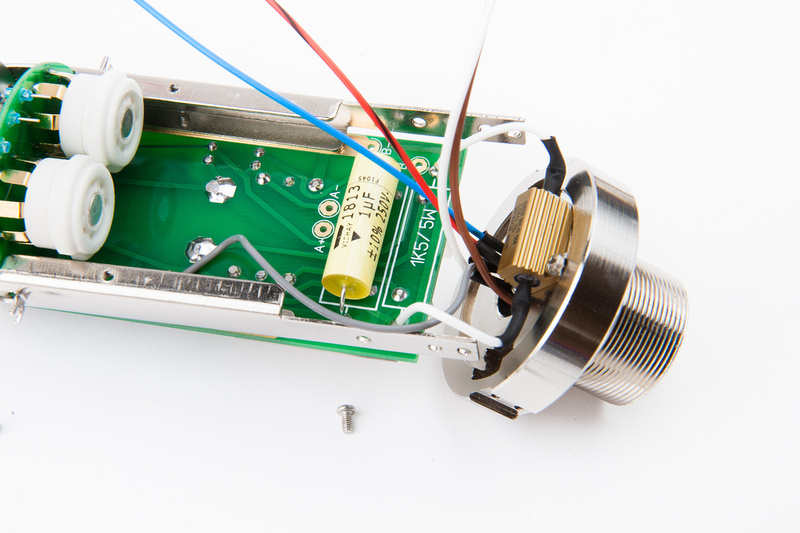

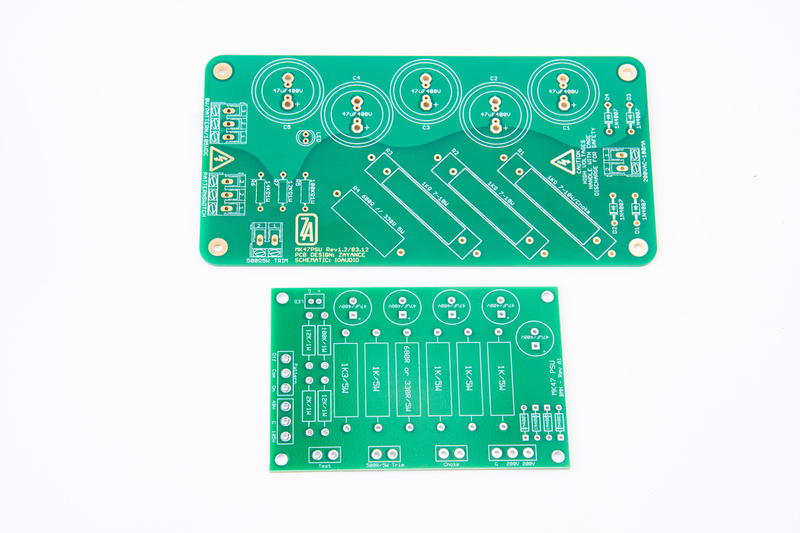

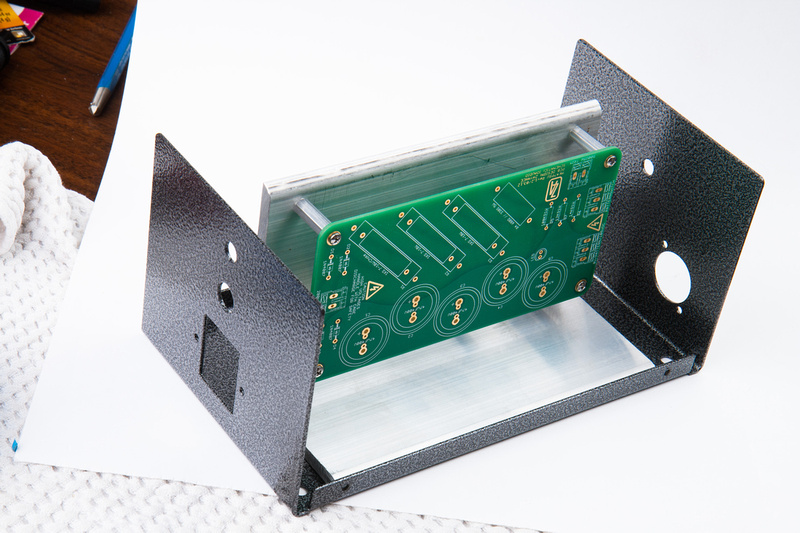

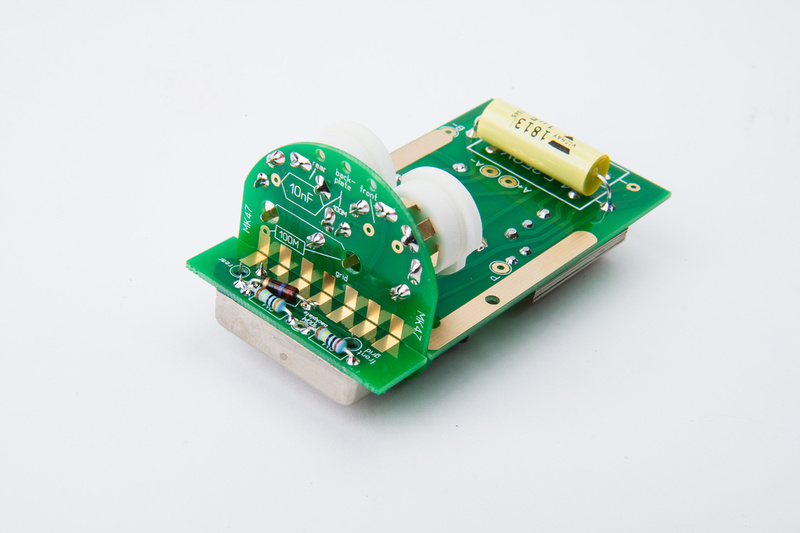

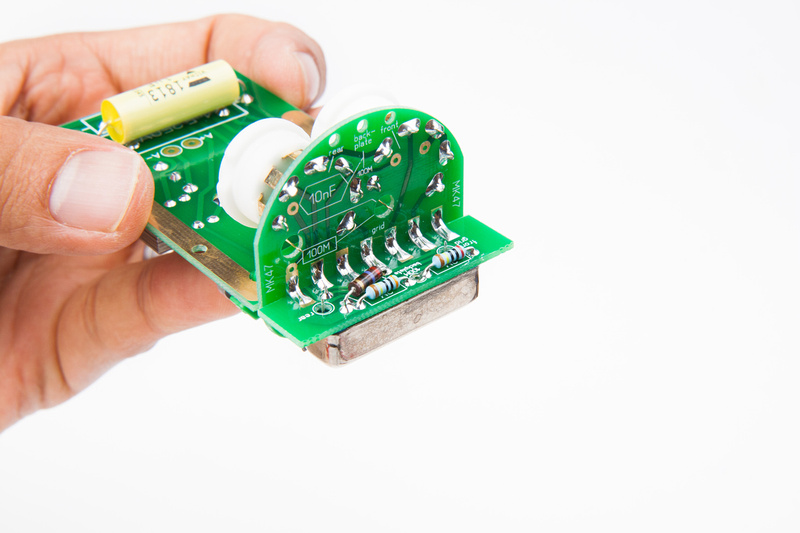

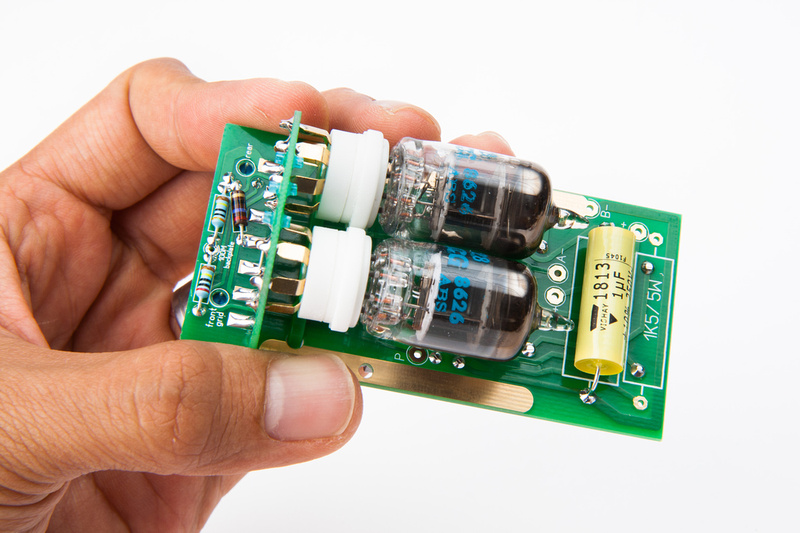

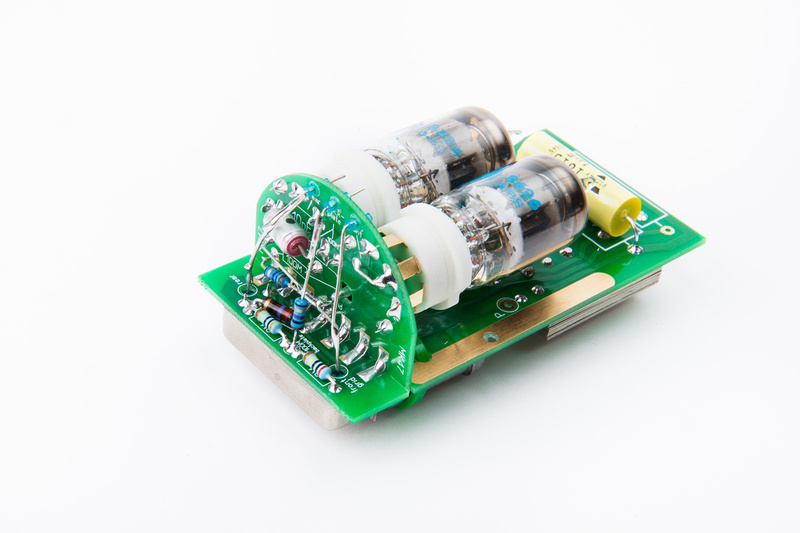

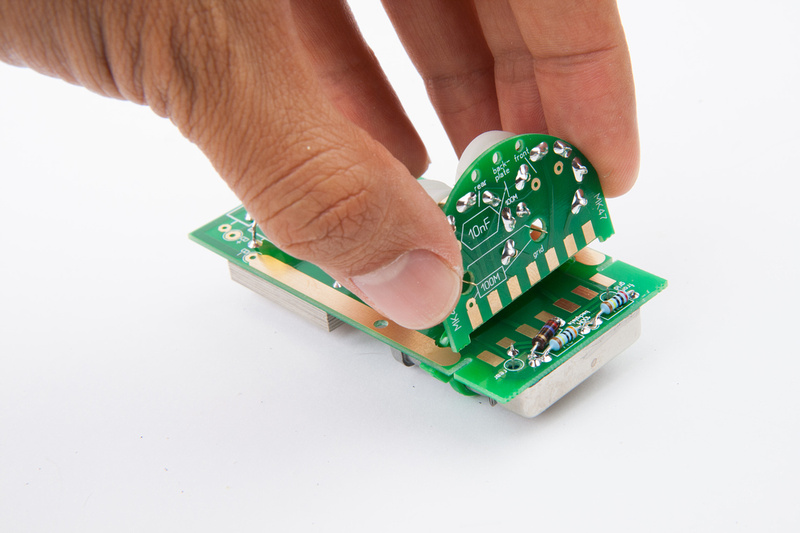

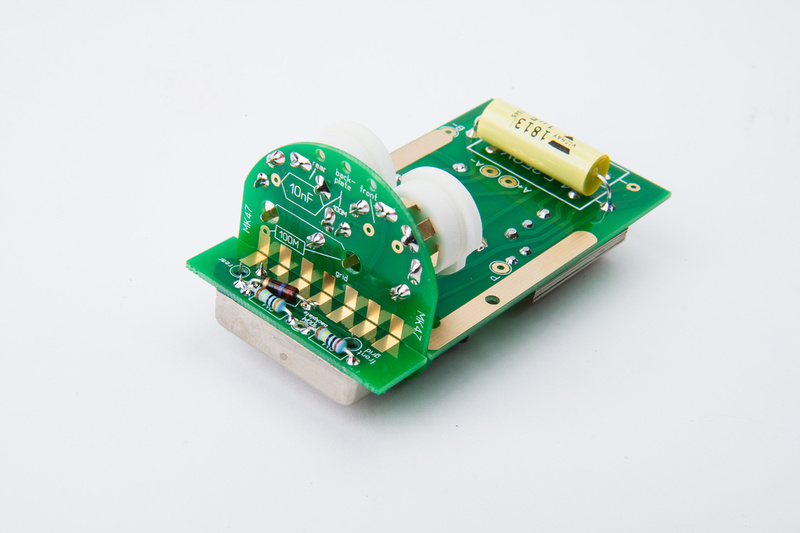

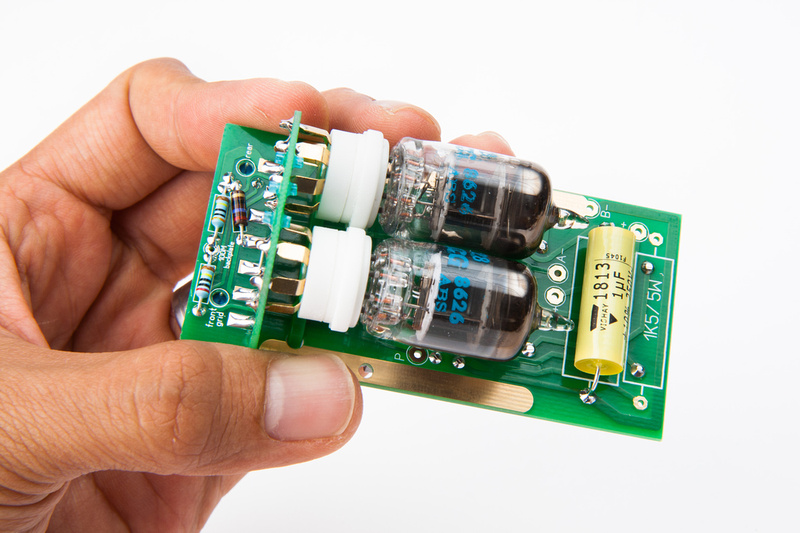

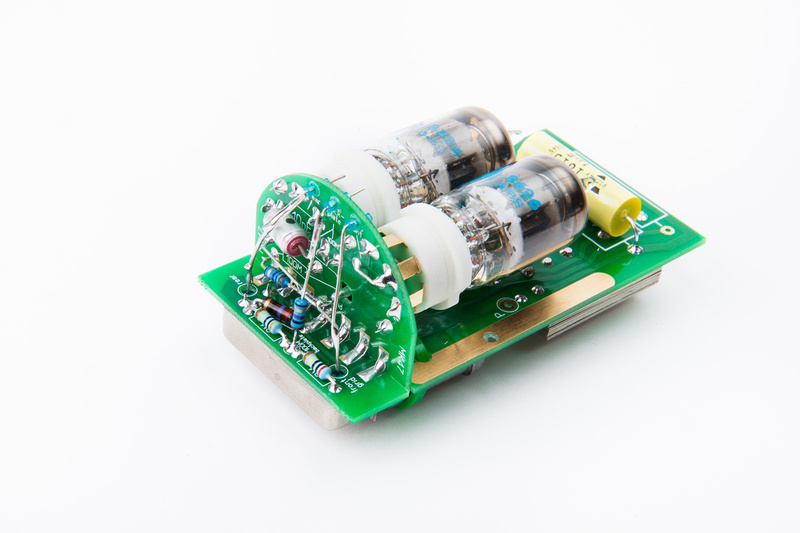

Next, I assemble the 2 pcb's.

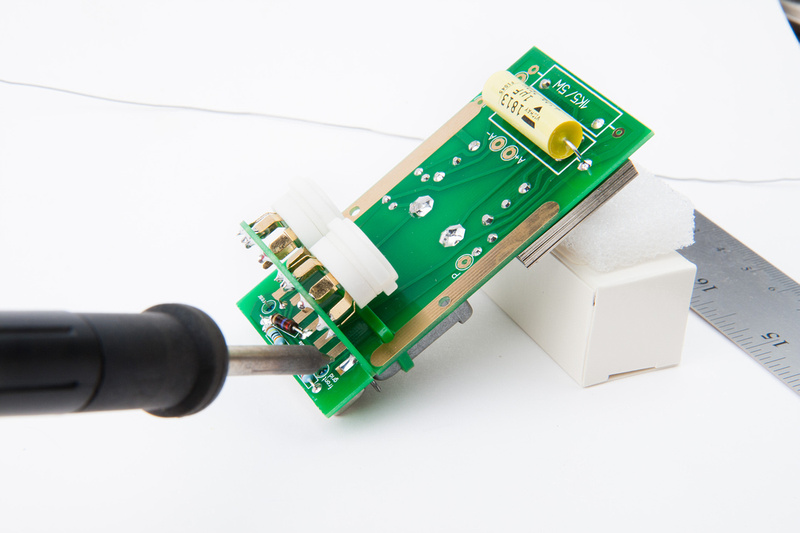

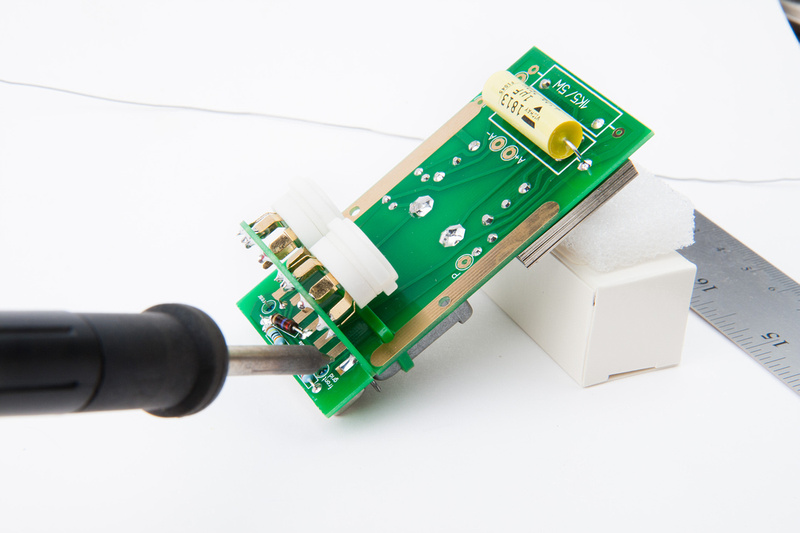

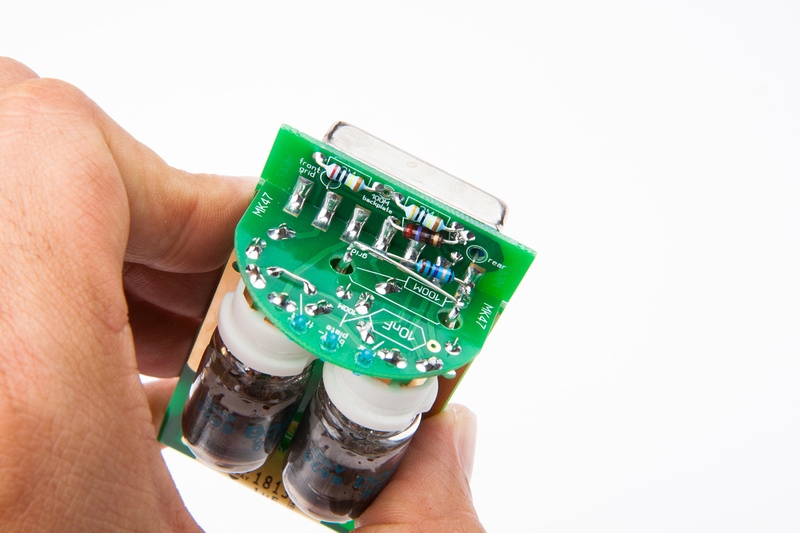

On my kit, this position aligned the 2 PCBs perpendicular to each other, so I propped the board up and solder one joint.

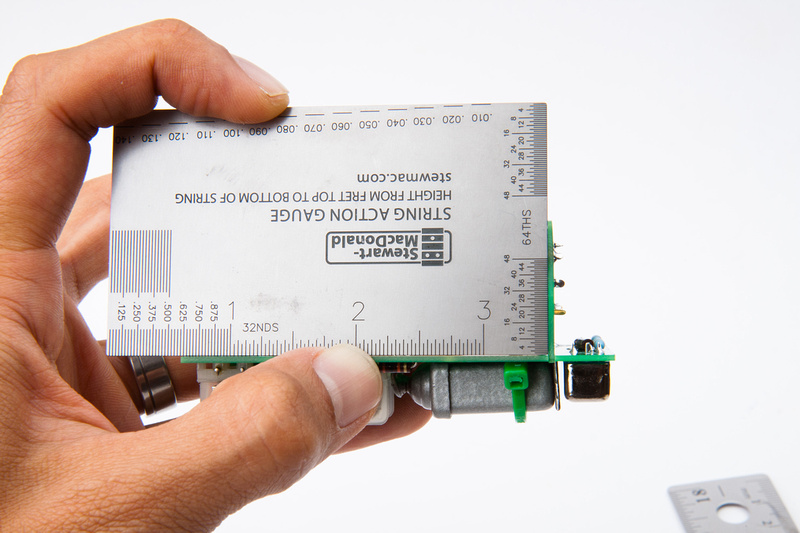

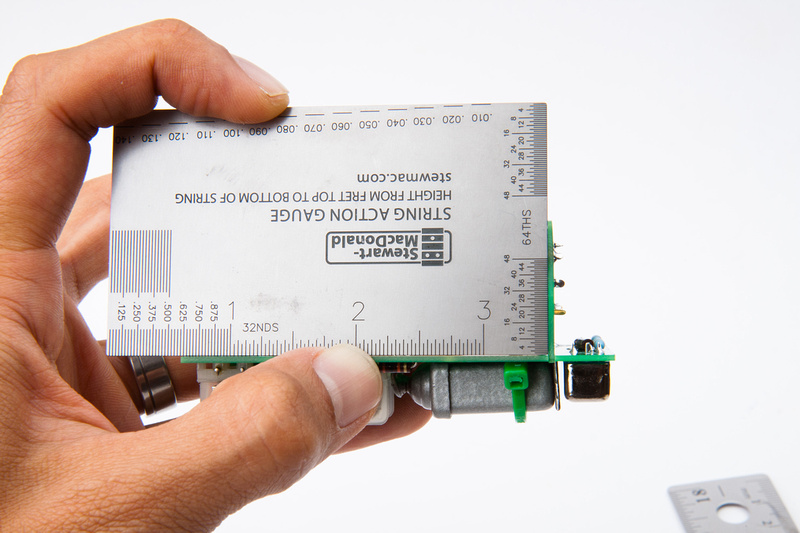

A square confirms that the alignment is almost perfect.

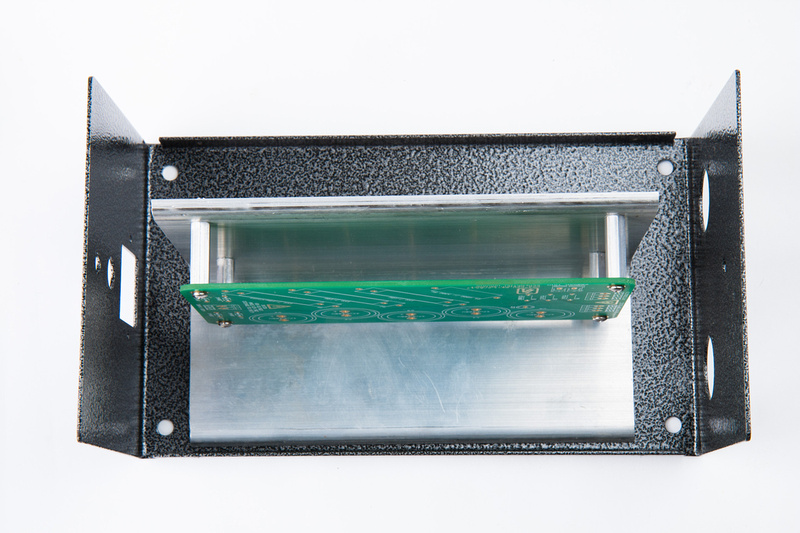

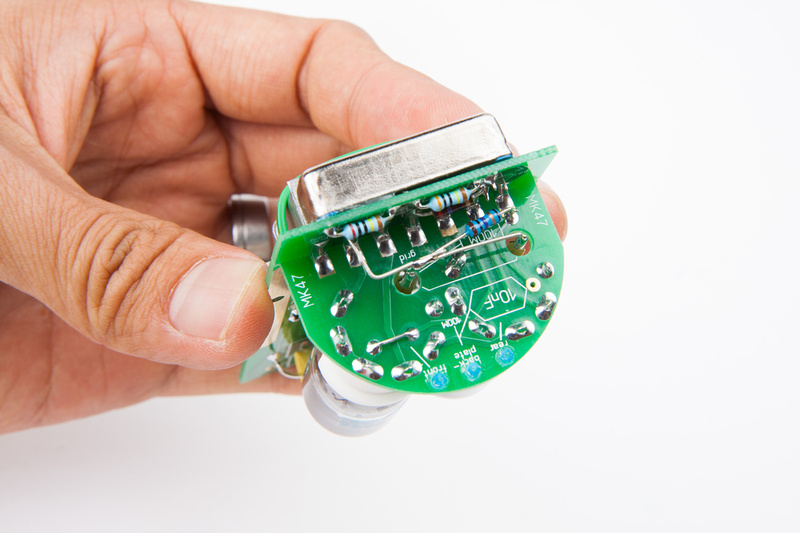

after soldering the remaining lugs, I clean the area with alcohol.

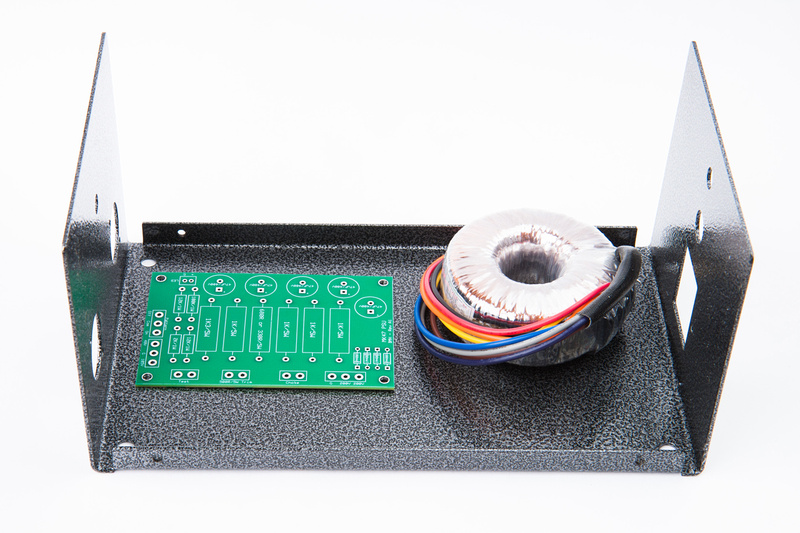

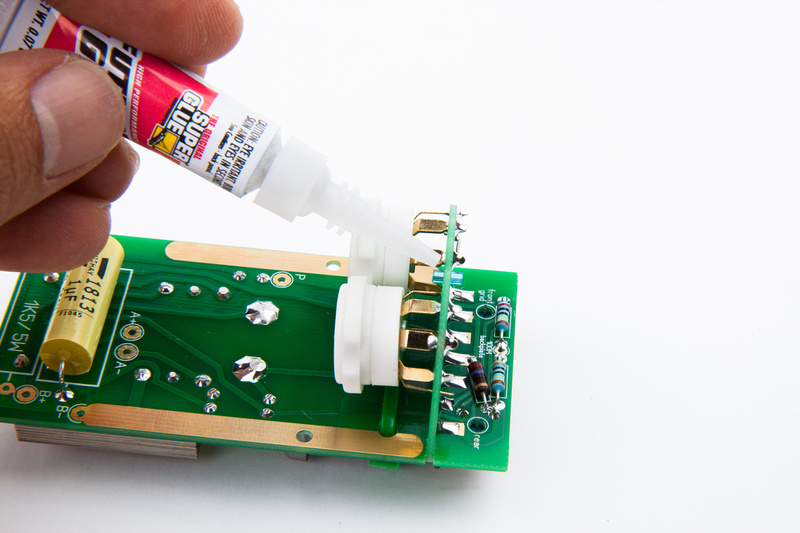

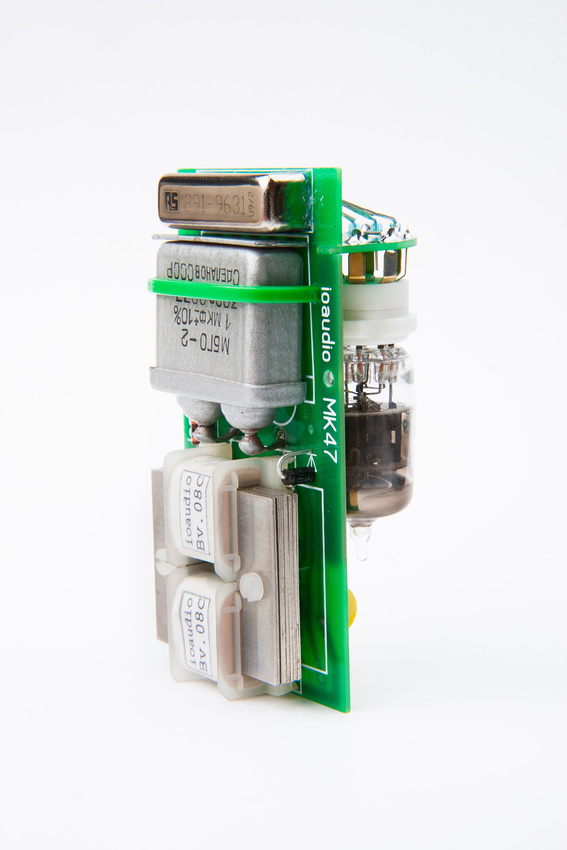

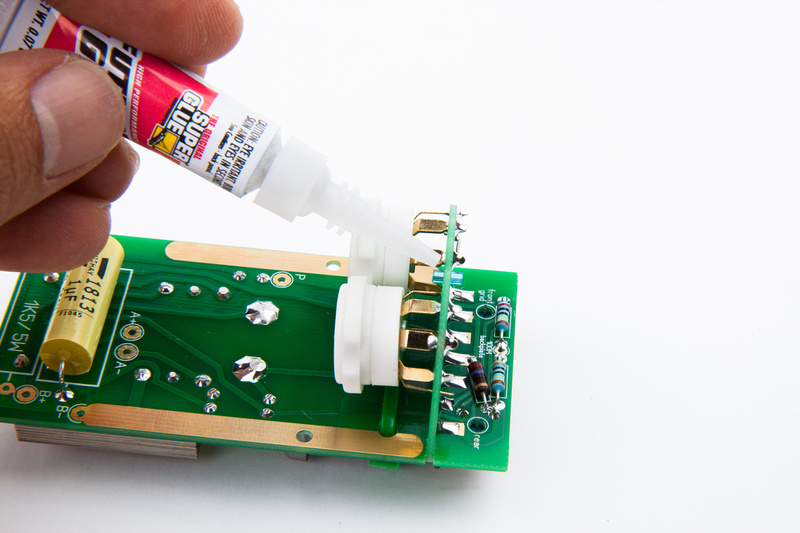

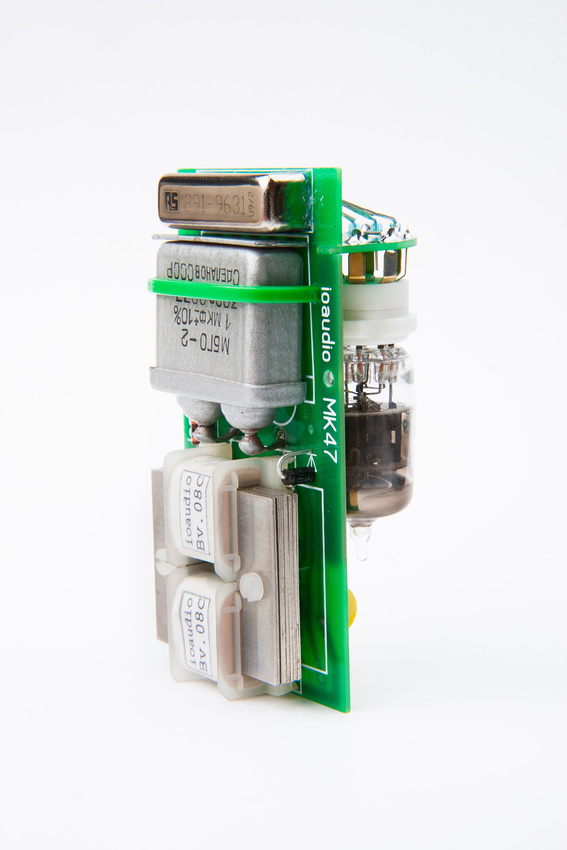

Next, I install the glass isolating tubes with some super glue.

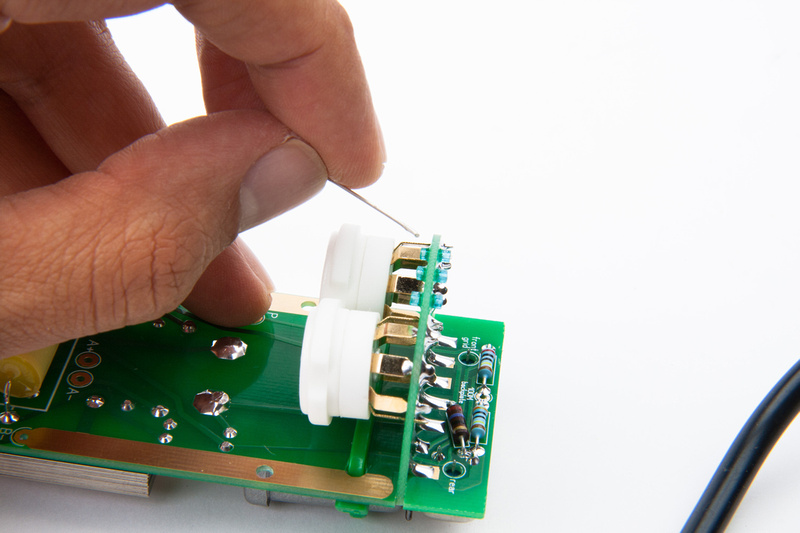

I discovered that it is much more precise to squirt a little puddle of super glue and dip a small component lead into it to dab the glue onto the glass tubes. Do not get any of the glue on the inside of the tubes.

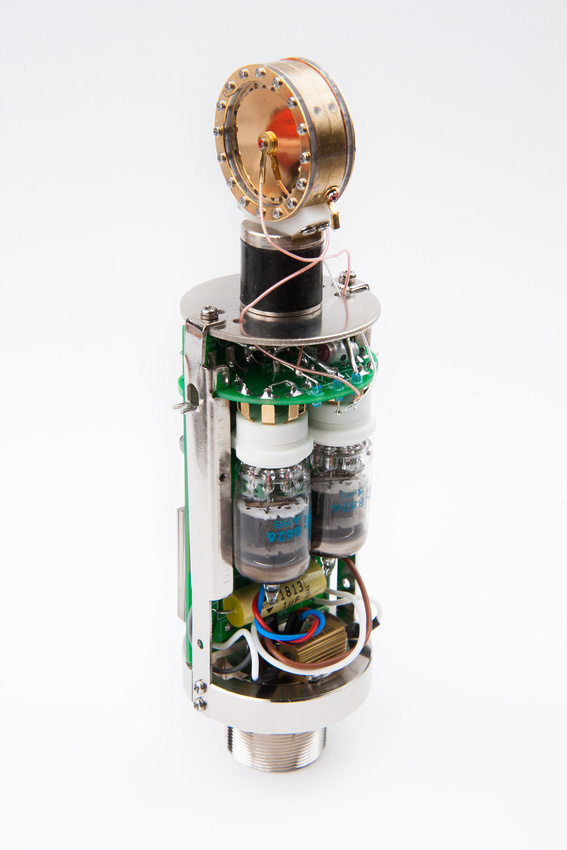

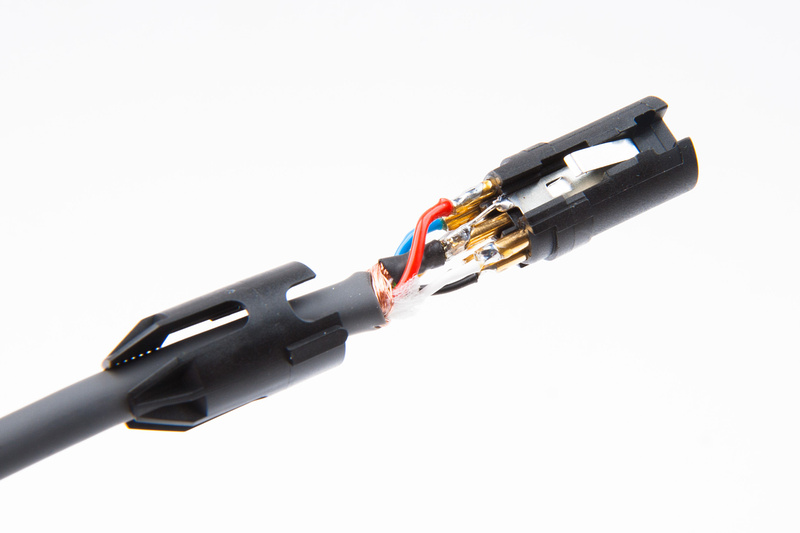

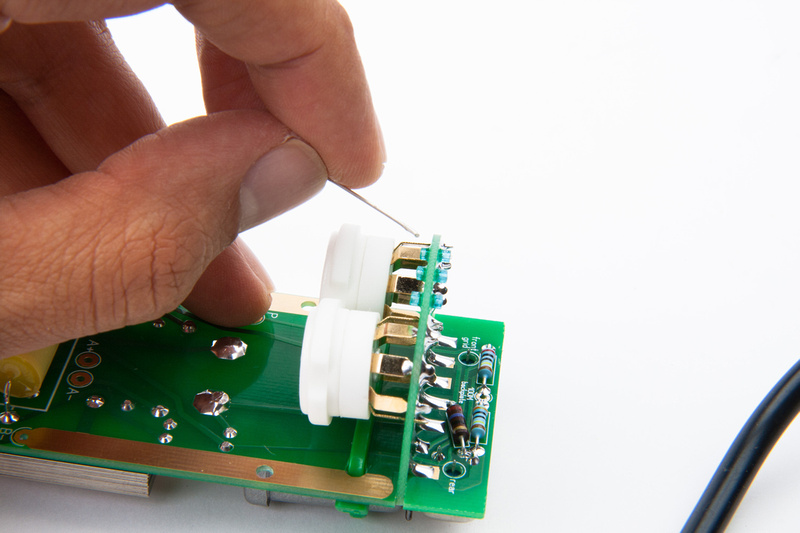

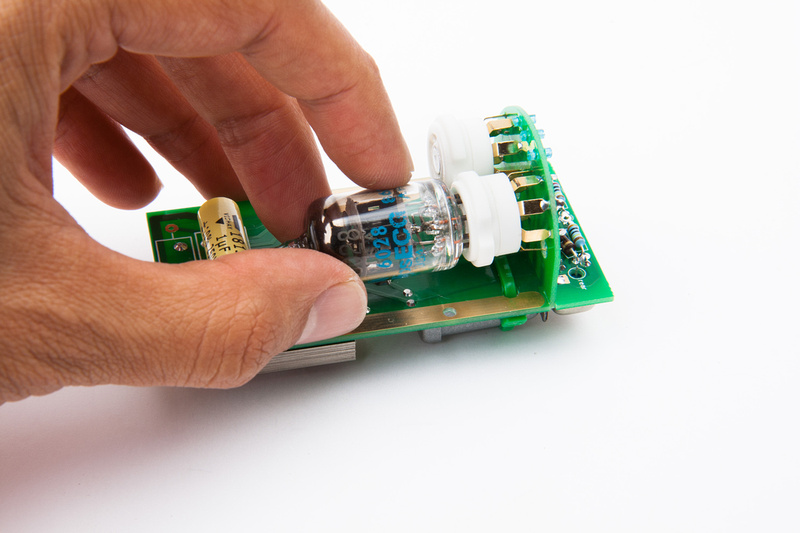

Next, I insert the tubes to push the socket pins into their fixed stationary positions.

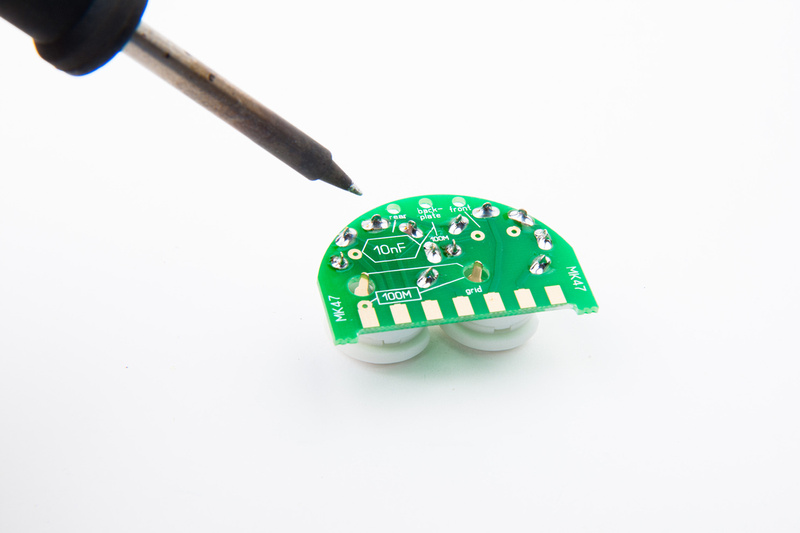

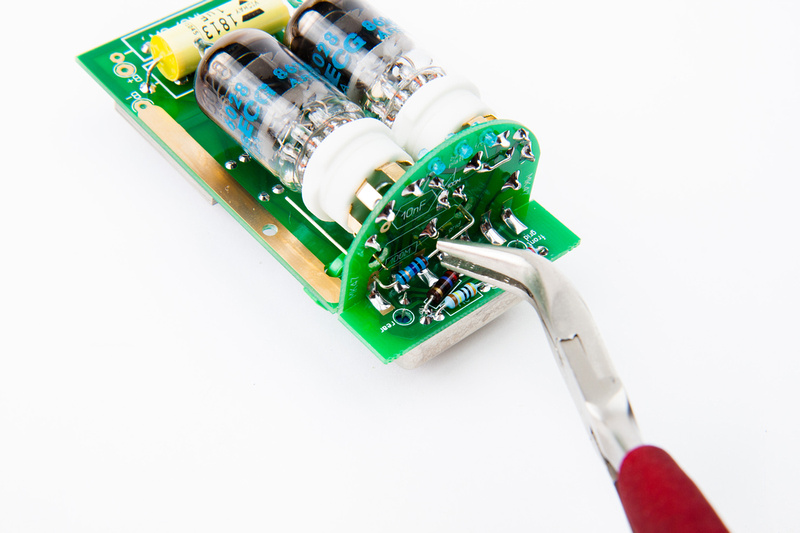

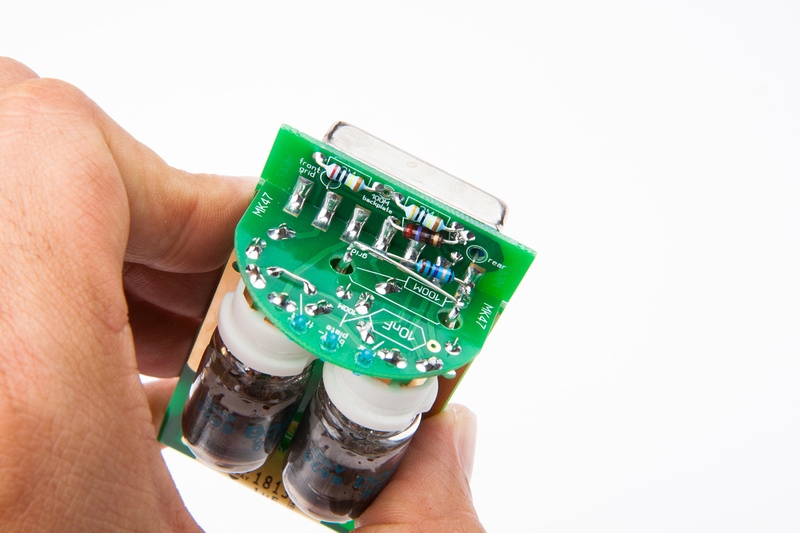

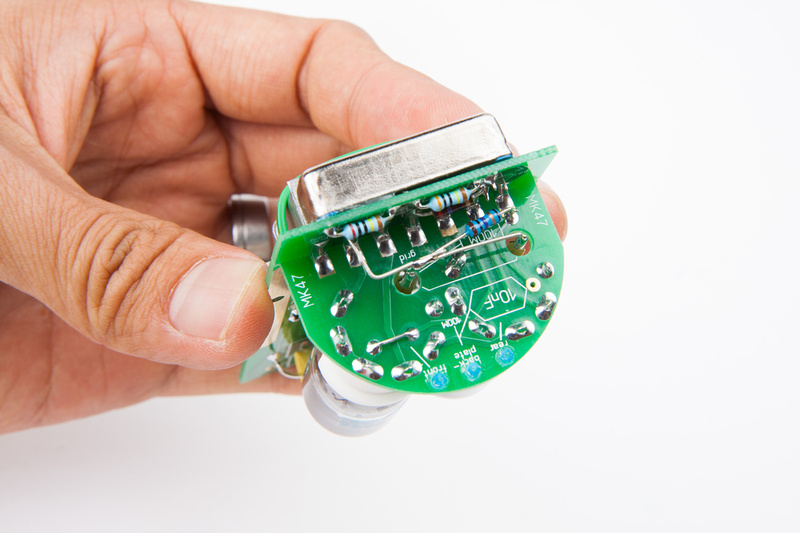

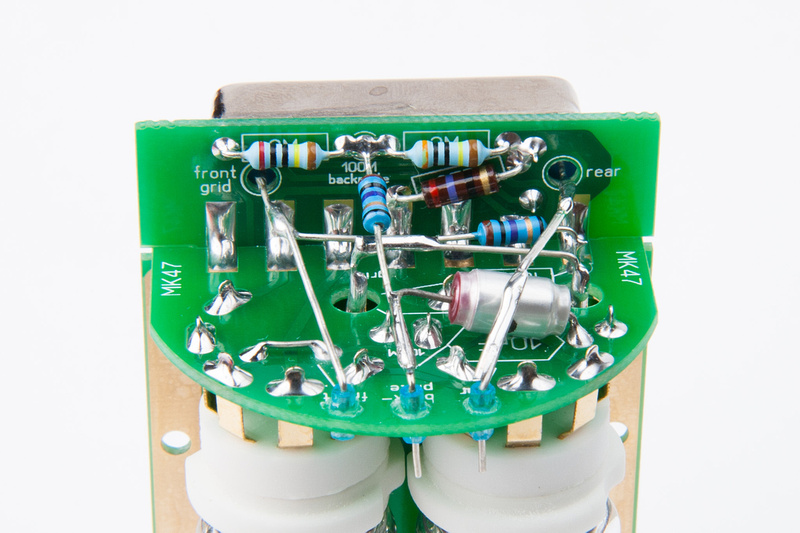

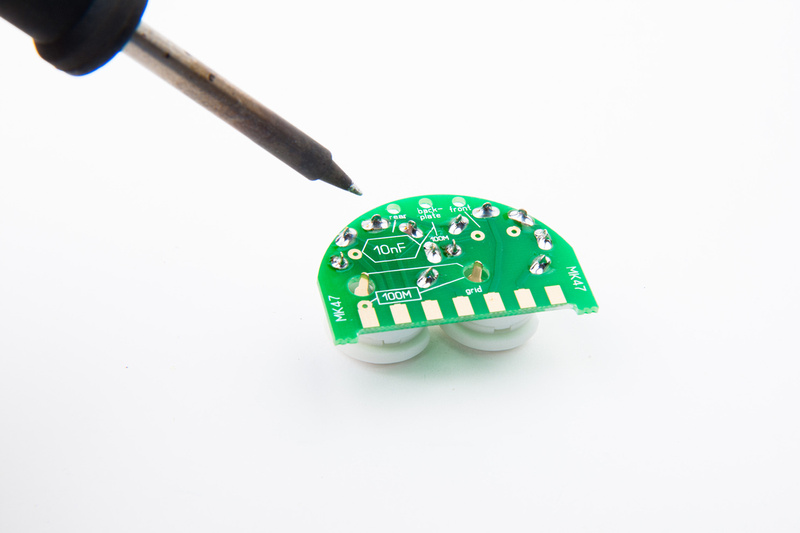

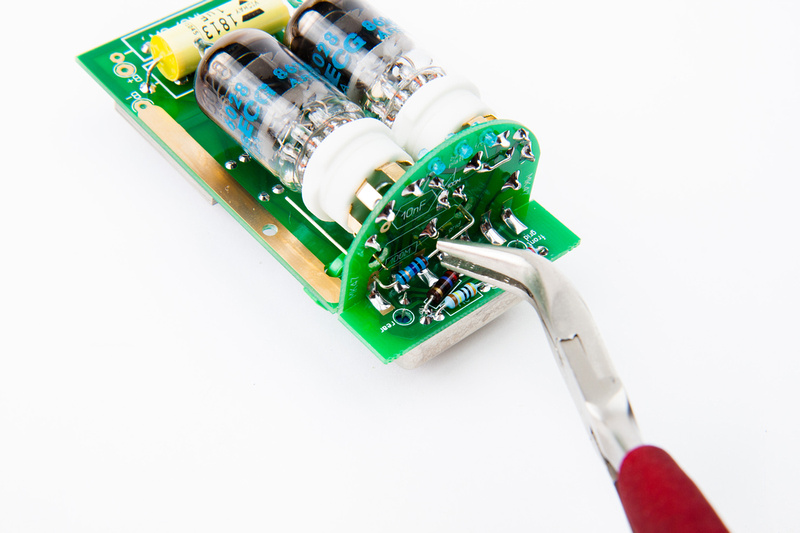

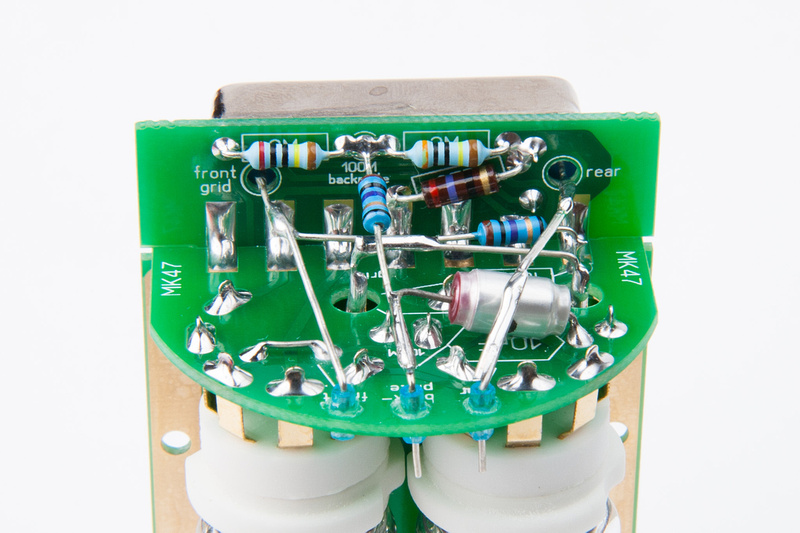

The, I begin assembling the floating high impedance portion of the microphone circuit starting with the 100M resistor. A little bit of creative clamping was executed to make the solder joints.

I ended up cleaning solder flux with alcohol as I went along making sure to avoid touching the capacitor with the alcohol. I was not sure if the casing was deigned to withstand it. I was not able to find a lead long enough to make the rear capsule lead connection in one shot, so I soldered 2 together.

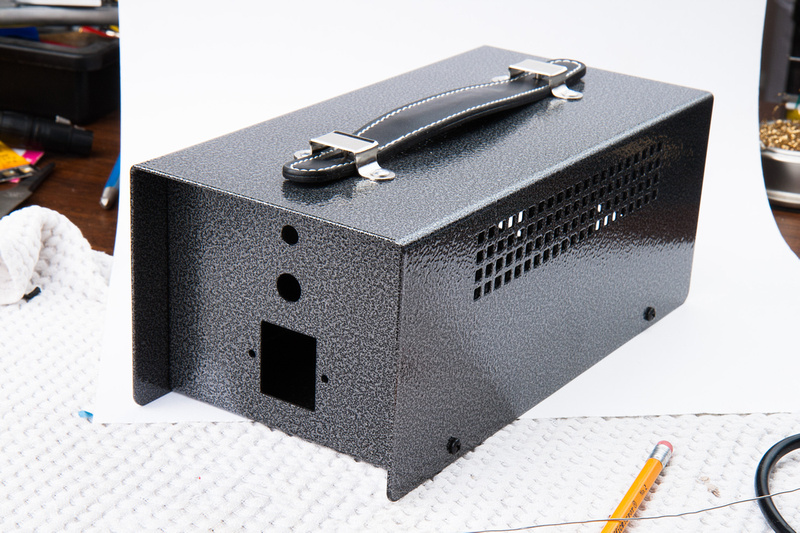

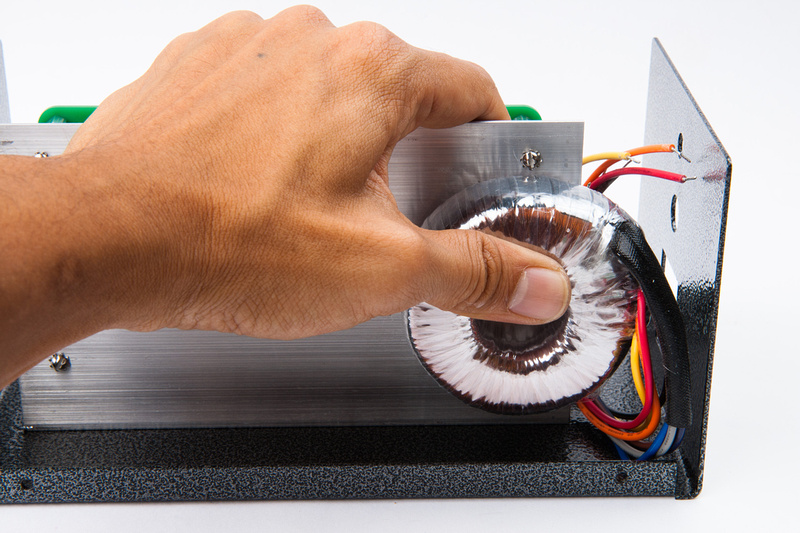

and, with the exception of the 1.5K heater resistor that needs to mount securely to the microphone body for thermal coupling, the internal circuit is completely assembled.

I must say, this is quite a fun build and the documentation on ioaudio's build thread made every step clear. I'm looking forward to finishing a mic as soon as a GT-2B body arrives from the motherland and my Beesneez M7 capsules arrive from Australia.

My tube pcb doesn't quite fit into the main pcb, so I round over the inside edges a little bit to make it drop in all the way.

And, of course, I take the opportunity to scrub the tube socket PCB at this time with isopropyl alcohol to clean the flux residue off.

Next, I assemble the 2 pcb's.

On my kit, this position aligned the 2 PCBs perpendicular to each other, so I propped the board up and solder one joint.

A square confirms that the alignment is almost perfect.

after soldering the remaining lugs, I clean the area with alcohol.

Next, I install the glass isolating tubes with some super glue.

I discovered that it is much more precise to squirt a little puddle of super glue and dip a small component lead into it to dab the glue onto the glass tubes. Do not get any of the glue on the inside of the tubes.

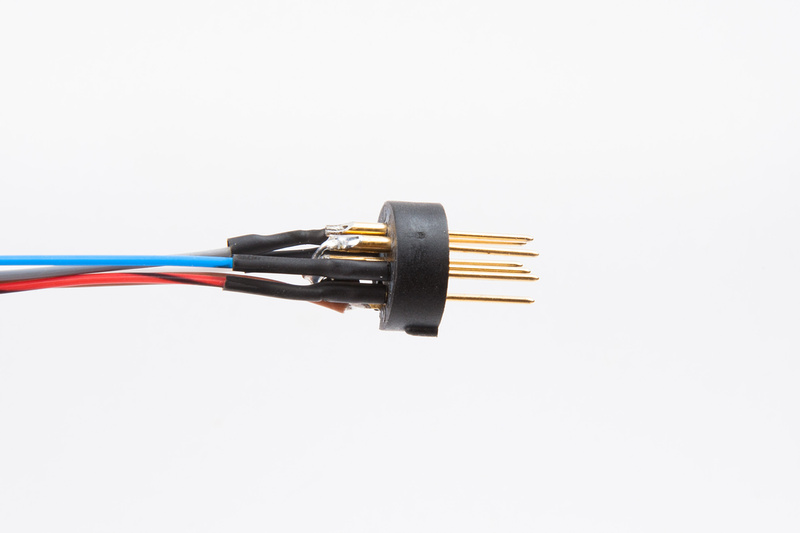

Next, I insert the tubes to push the socket pins into their fixed stationary positions.

The, I begin assembling the floating high impedance portion of the microphone circuit starting with the 100M resistor. A little bit of creative clamping was executed to make the solder joints.

I ended up cleaning solder flux with alcohol as I went along making sure to avoid touching the capacitor with the alcohol. I was not sure if the casing was deigned to withstand it. I was not able to find a lead long enough to make the rear capsule lead connection in one shot, so I soldered 2 together.

and, with the exception of the 1.5K heater resistor that needs to mount securely to the microphone body for thermal coupling, the internal circuit is completely assembled.

I must say, this is quite a fun build and the documentation on ioaudio's build thread made every step clear. I'm looking forward to finishing a mic as soon as a GT-2B body arrives from the motherland and my Beesneez M7 capsules arrive from Australia.

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)