OK. . . a bit of fun with the new "C12 prototyping PCB" that Matador recently designed to fit the HT-11A donor microphone. With all this jabber about isolated circuits vs. pcb, I thought I'd like to show the flexibility and options our kits have for building pretty much whatever you want inside the HT-11A donor platform cleanly and solidly. This allows for a true isolated point to point construction of the circuit while maintaining all of the wiring and noise benefits of a proper ground plane.

This is not meant to be a paint-by-numbers step-wise guide as anyone laying out a design for point to point wiring should refer to the schematics often, but of all the build possibilities on the Proto PCB, this is perhaps the easiest because the "regular" C12 PCB set provides an almost direct road map for the required wiring connections.

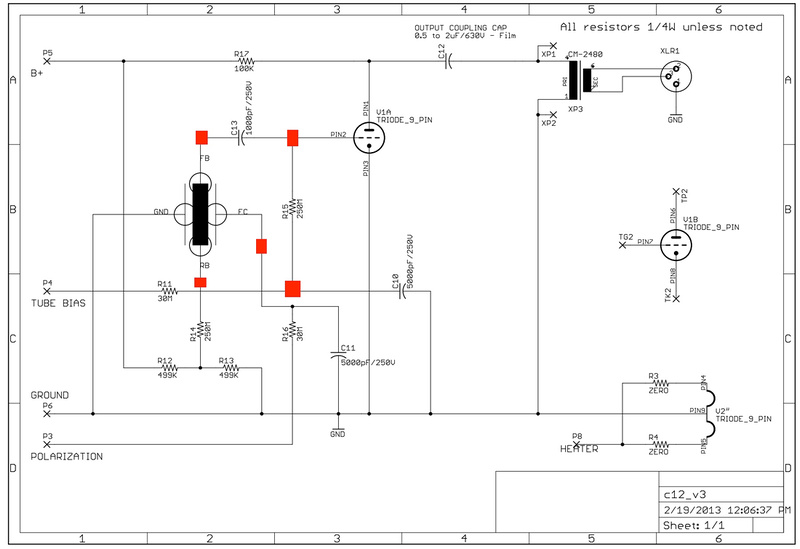

For reference, even though I am teflon isolating almost the entire circuit in this build, and we feel our standard C12 PCB design is a robust and proven execution of the circuit, Matador informs me that technically speaking, these are the only Hi Z nodes in the circuit that would be of any small significance to isolate on teflon standoffs.

It should be noted that all of the techniques used in this demonstration of the new "prototyping pcb" can also be deployed on the regular C12 PCB if one wishes to isolate any part of the circuit with teflon and wire those portions point to point with silver teflon wire.

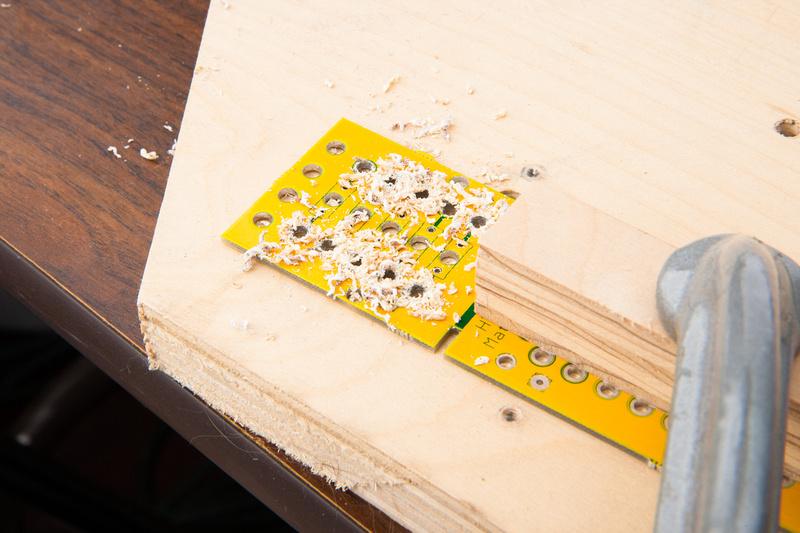

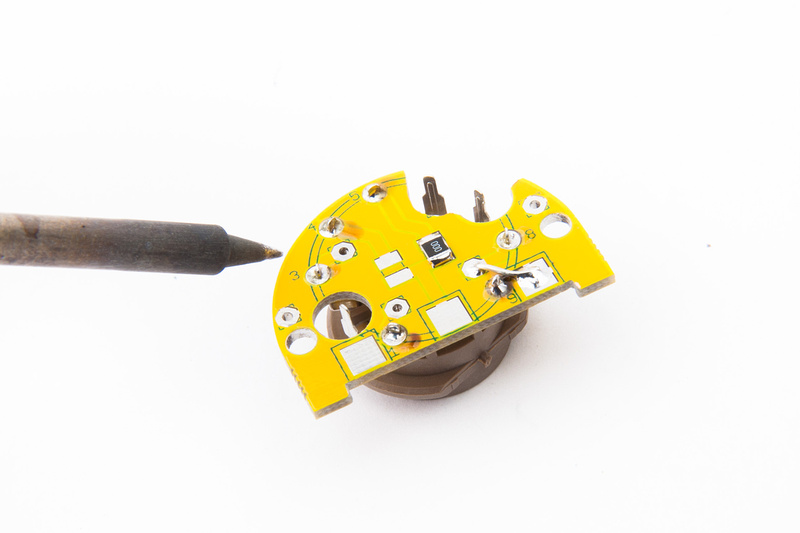

To start, I drill out the required holes to mount keystone teflon standoffs. I use a 9/64 inch drill bit which worked well for a good friction fit.

A quick test fit revealed that the outer edge standoffs would be too tall to fit inside the HT-11A tube.

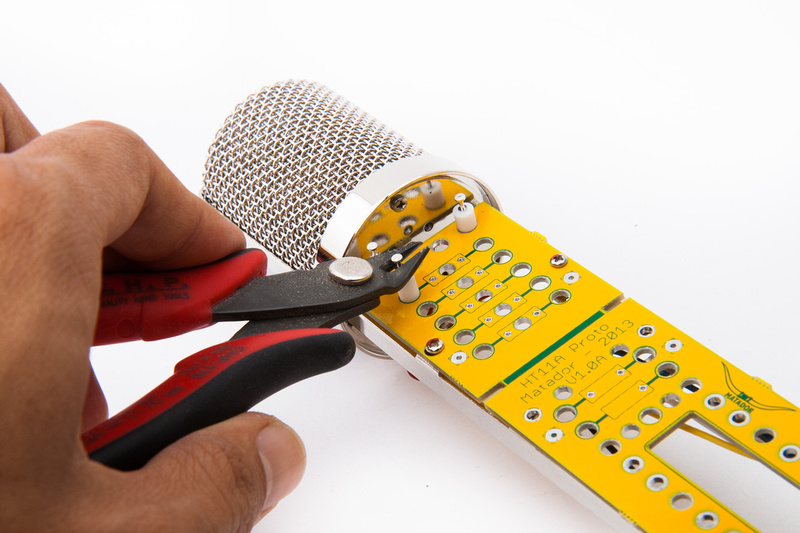

Wire cutters make quick work of cutting off the top section of the standoff.

And clearance has been restored.

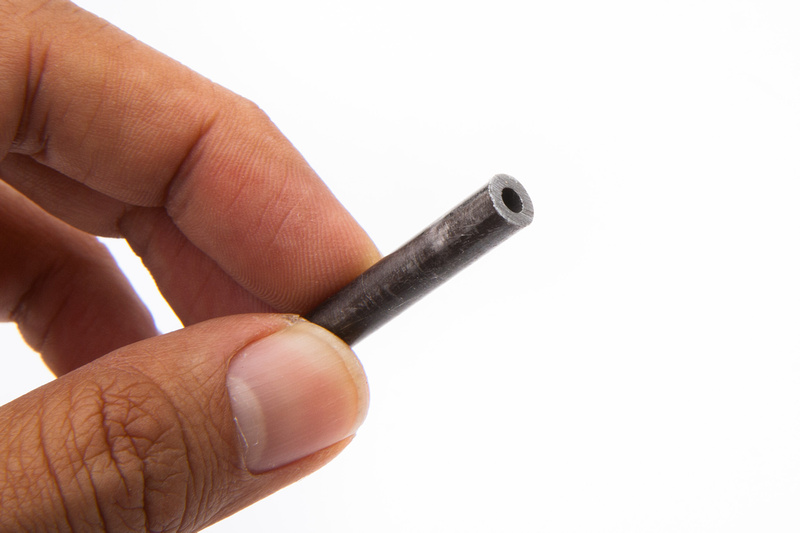

This is a tool I purchased from tubedepot.com when I was building a turret board based point to point power supply for ioaudio's mk47 microphone kit. It is used to drive turrets into the board without damaging the fragile turrets.

I used this tool to help hand press the teflon turrets into the PCB. A bit of side-to-side wiggling is necessary to seat the teflon turrets all the way in.

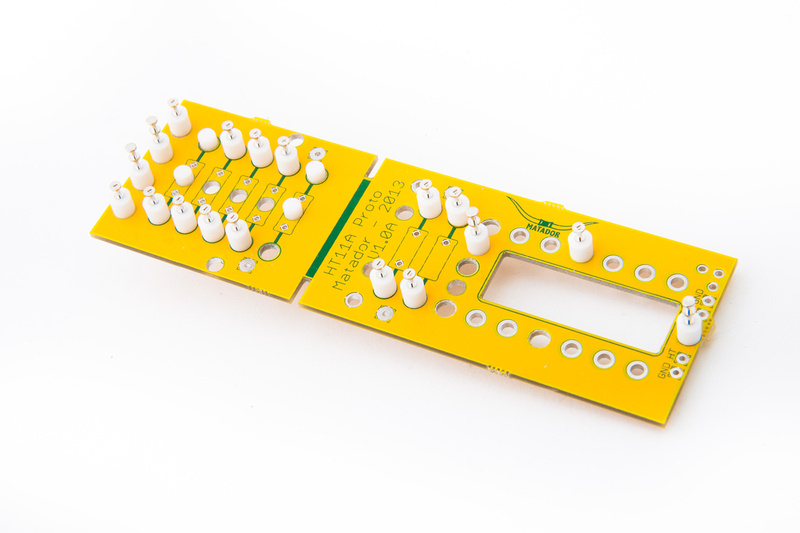

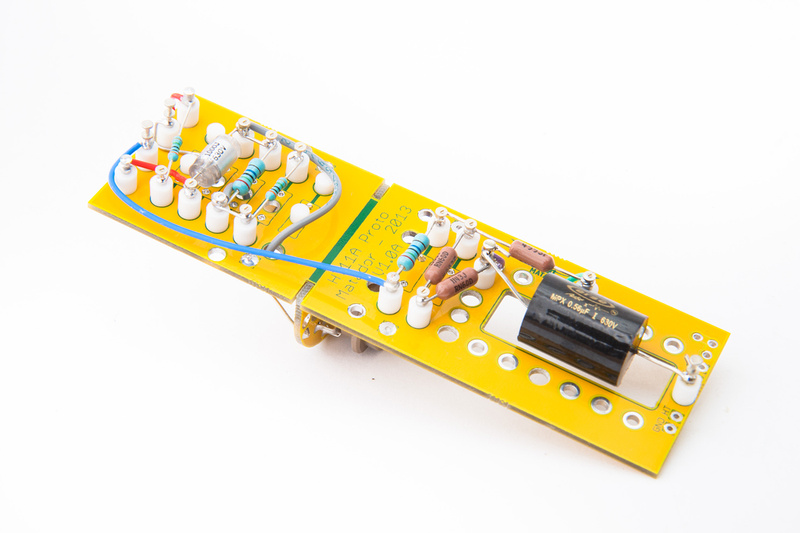

And, here are the turrets installed. I'm sure there are prettier and more elegant solutions in terms of layout, but I think this will work.

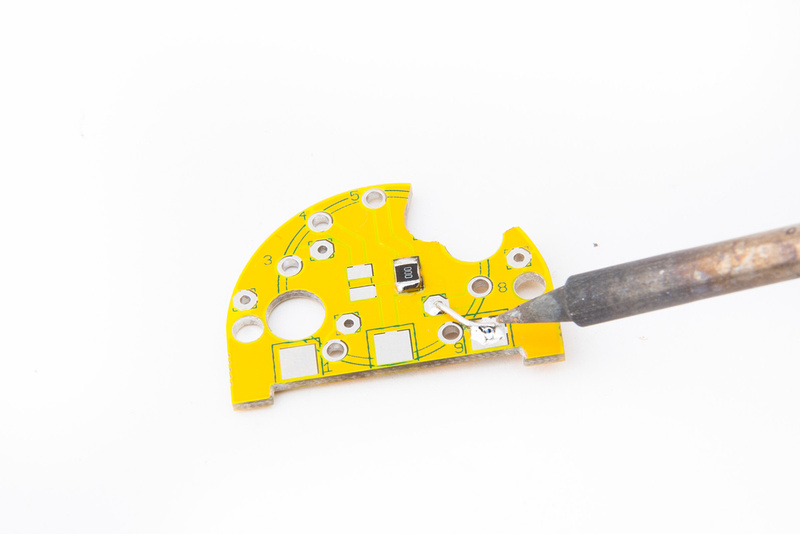

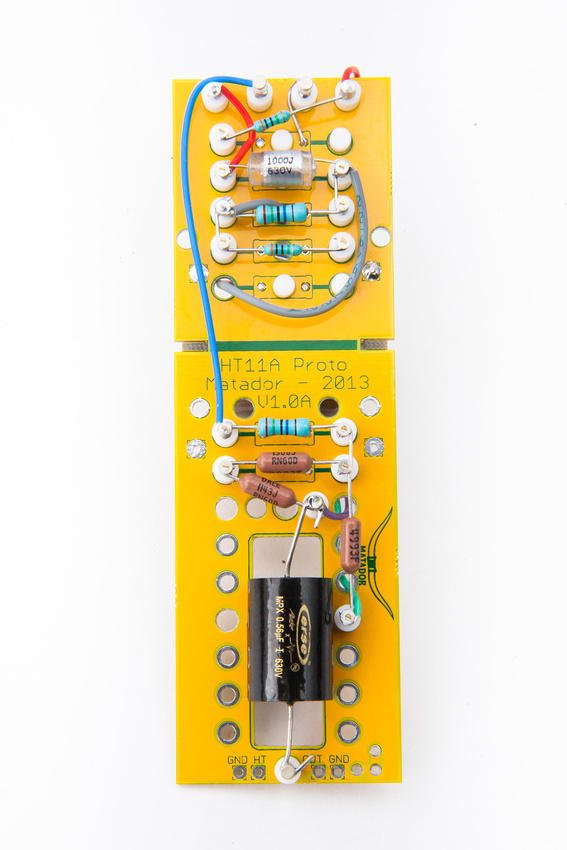

Next, I install all of the components except the polystyrene capacitors because those are sensitive to the 90% isopropyl alcohol I use to clean the assembly. It is much easier to clean when you can dunk the entire assembly into the liquid and scrub with a toothbrush, so I leave the sensitive components for last. I install all components with a 1/2 turn around the turret post to make sure each connection has a solid mechanical contact before soldering.

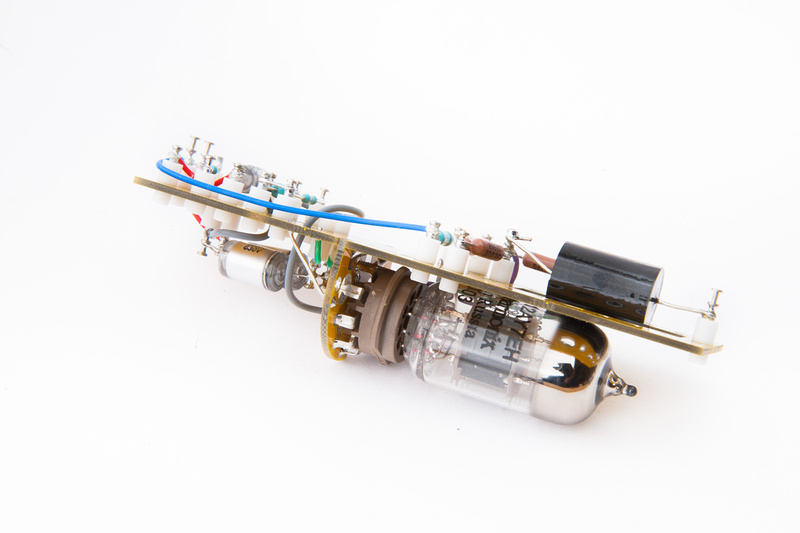

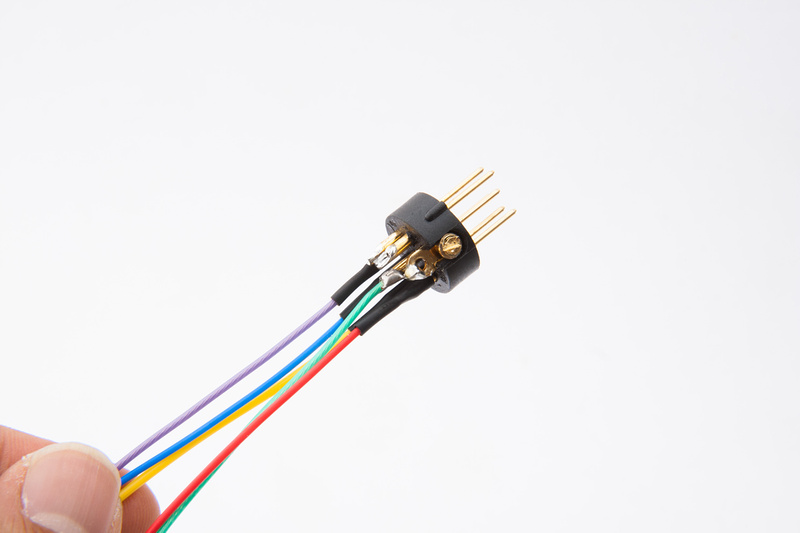

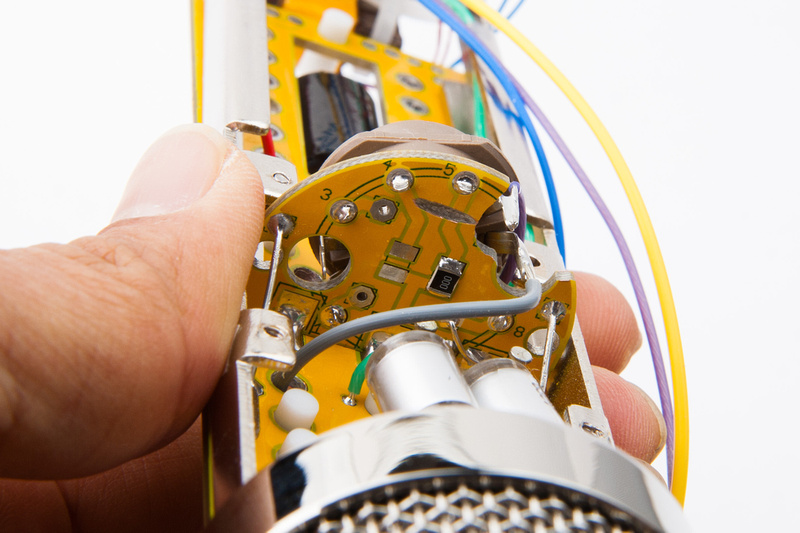

The only PCB trace that I will utilize in this build is the heater supply voltage. I will also utilize the "2nd half" of the tube as my other microphone build uses the "1st half" this way, I will have a pair of mics I can swap tubes between and double up on my tube life expectancy. The Grid connections (pin 2 and 7) are already isolated on Matador's PCB, and the Cathode node (pin 8 ) simply connects to the ground plane, so I drill out the Plate node (pin 6) so my build will be fully isolated except for heater supply (pin 5) as previously noted.

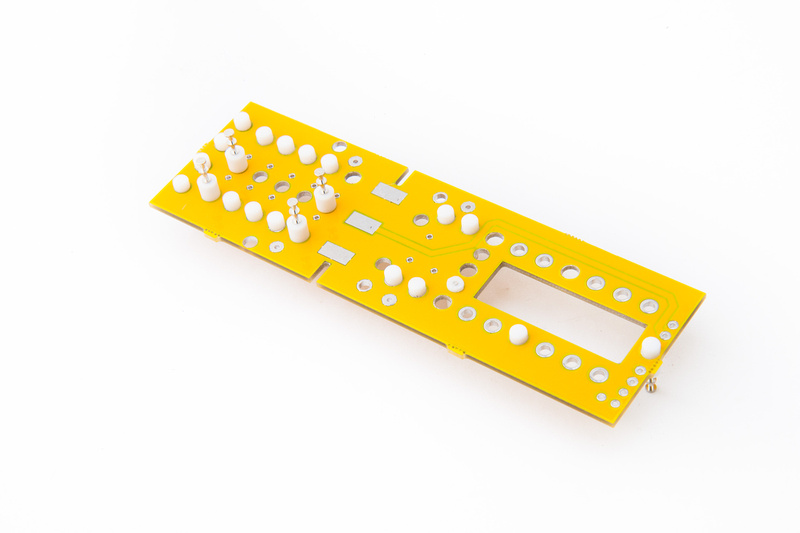

The jumper for heater supply is installed and an efficient jumper to ground installed for our Cathode node (pin 8 ).

And we dunk the entire mess into 90% isopropyl alcohol and scrub the solder flux off.

Next, I solder in my resistors and make my PCB wiring connections. Some utilize leads cut off from my resistors and the rest use silver teflon wire.

And, it's never a bad idea to clean thoroughly, so I dunk the assembly in isopropyl alcohol and scrub. The reason I use a small plate is so I can change the alcohol often. The more you use the solution, but more flux is dissolved into it, so changing the liquid often is helpful.

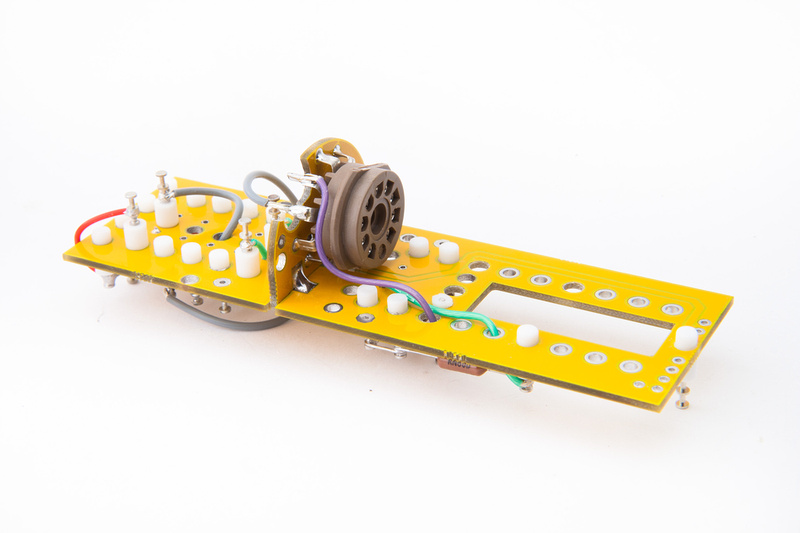

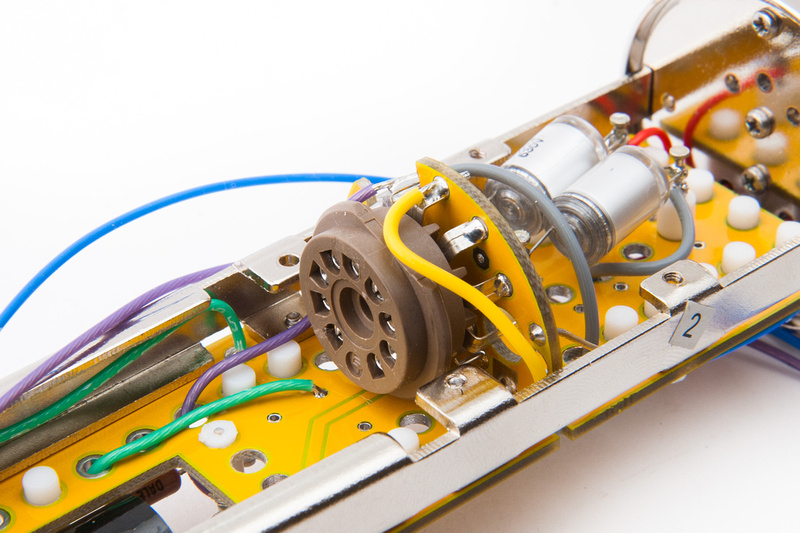

Next, the tube socket is soldered in.

and cleaned thoroughly.

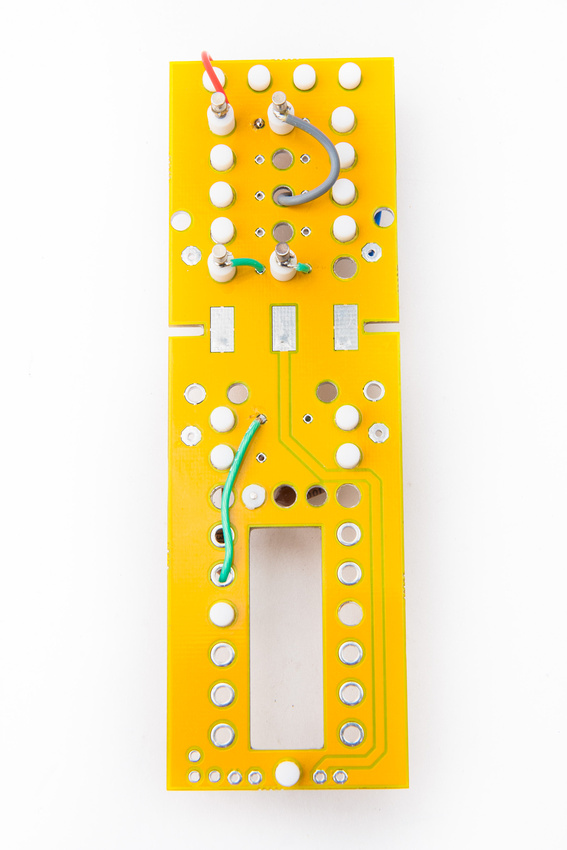

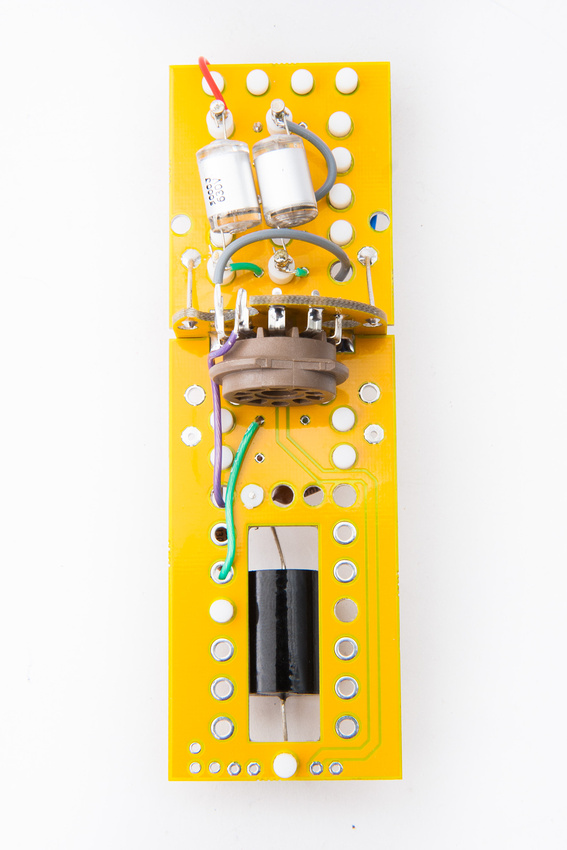

The tube board is then soldered to the main PCB and connections for the Grid (gray wire) and Plate (purple wire) are made point to point. This is the last opportunity to dunk the entire assembly into the IPA solution, so I clean one last time very throughly

. . .and then install the capacitors completing the microphone PCB build. More connections will need to be made to the 7 pin XLR jack at the base of the microphone and to the output transformer.