shabtek said:

Skylar--maybe the post was edited but do you still have that link for the solder paste vendor?

thanks

I did not edit the post.

Post #391 on Page 20.

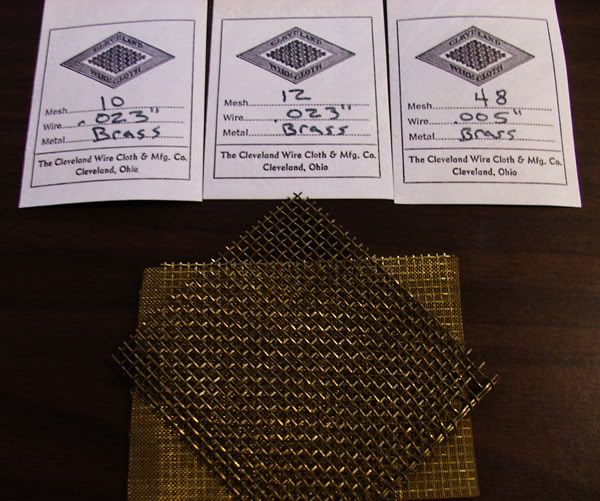

It's not solder paste, but welding rod.

Looks like pretty heavy-duty stuff, but you'll have to use a torch or heat gun.

This method will require more patience and time.

Solder Paste could be a much better alternative.

I've ordered several different low-temp solder paste alloys that I am going to experiment with in order to find the most ideal solution for the headbasket assembly.

I plan to use an oven, so that I don't have to do these one-at-a-time.

I will, of course, let you all know my results.

Jonkan said:

Skylar, do you have any further guesstimate on how much a complete body kit will cost? And how much with the psu box kit aswell?

/Jonas

I think it may be too early to start guesstimating on price.

But I can say that I was able to negotiate the price of the metalwork down near my original goal.

That's all I'm going to say for now.

I don't want to give a price estimation now, because there are still a lot of unknown variables.

Everything's coming into place, and it won't be too long before all of this stuff is figured out.