Everyone,

I plan to give out my drawings next week...probably Monday.

I just wanted to spend some time working with the parts to get them as close to "final" as possible before distribution.

Usually, a commercial product design takes months to develop; here we've only spent days!

...a bit quicker than what I am use to.

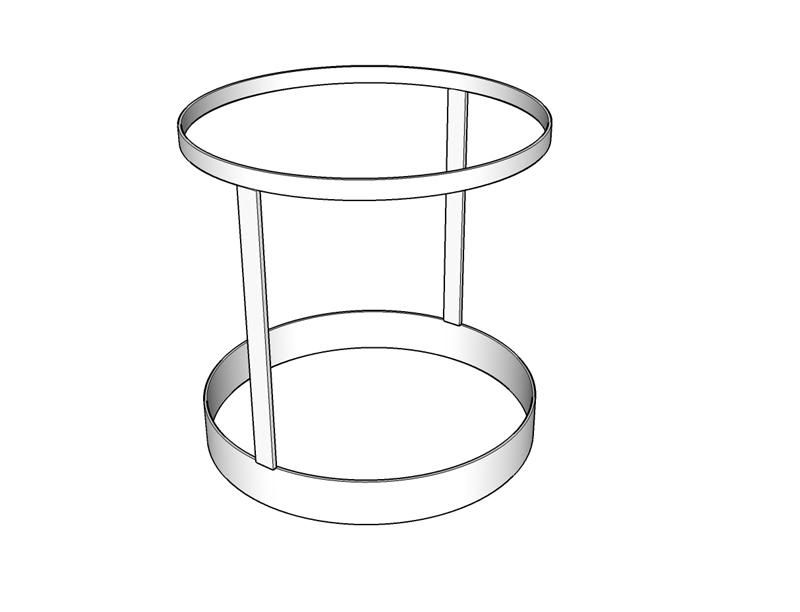

I will probably want to alter the design of the head basket with these new figures from bradb before we pull the trigger on manufacturing.

So, whatever I release on Monday will probably not be final. Rather, just a reference design with which to get ballpark prices.

I don't really like the idea of us doing all of the beta design and testing for someone else's profit, as Moby said. This is why I have always shyed away from China...it's like the wild, wild west over there. There are no rules! No business ethics! I don't intend to offend anyone by saying that, but there is truth to what I say.

I'm kind of wary of publishing these designs publicly simply because I don't want some company making a bunch of money off of something that I just want to share with DIY'ers. This is an issue that crops up repeatedly on this forum!

Hopefully, we can get this thing made, providing a quality solution for those who want this type of mic body for a reasonable price.

No one's trying to make money here.

So, I will gladly share the design with any forum member who wants to quote the design with a machine shop, and get some bodies made for all of us!

BUT, I am kind of a perfectionist, so I want to hammer out all of the details of the design before I "release it to the wild," as it were.

So, I just ask that everyone be patient; this is definitely not "vaporware."

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)