Thanks for the kind words everyone.

mitsos,

Note how the mounting rails attach to the capsule mounting disc. If the mounting rails were L-brackets, how would they then attach to the mounting disc? Such a part would have to be machined, which would be a more expensive part than flat rails as designed + separate L-brackets + fasteners combined. Plus, the flat design allows for more flexibility in mic innards.

I

Martin,

On the original u47, it's my understanding that the "hole" for the original Tuchel connector is actually an extruded cylinder with the threads "built-in."

Looks to me as if those end-caps were die-cast.

If we replicated that part exactly, I think it would have to be die-cast, which is prohibitively expensive for our quantities.

Even if we went ahead and did that, the connector options would then be very limited, and it would be tough to try to fit anything in there other than the original Tuchel.

(I think these are reasons why the Flea bodies are so expensive!)

I like the look of the original Tuchel, mainly because it's just freakin' huge!

The Amphenol-Tuchel connector that I've spec'd is a lot like the original, except smaller and with cylindrical pins.

So, using this connector would give you a look similar to the original (the cable connector is even a screw-on type)...just smaller.

Does Neutrik have circular panel-mount connectors? I really dislike the rectangular ones for this application.

Can you give us more info on the military connectors you have found?

Maybe they've got something bigger that would closer match the look & feel of the original?

In the end, I think people will probably want to do different things with the connector, so if we start with a basic, smallish hole, it should be easy enough to enlarge that to your needs.

Just an idea.

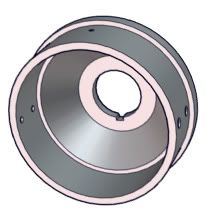

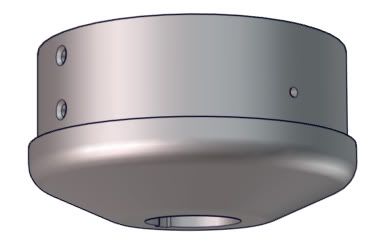

Here are some better shots of what the end cap looks like.

ioaudio,

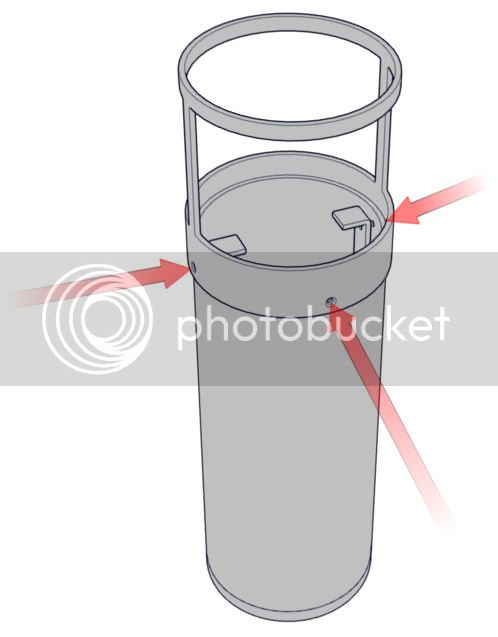

The headbasket does have three screws. There are two on the sides and one in the back.

Originally, I had them set up at 120°, but I changed from a 3-rail to 2-rail inner design, which forced these to change.

The two side screws that secure the head basket must also secure the inner rails, which is why I cannot put these at 120°.

Here's a shot that better shows the screw layout from the rear.

I'm not sure I understand what you mean by a groove for the 3 layers of mesh.

Can you post a reference picture of what you're talking about, so that I can add that in?

Thanks everyone!

~Skylar

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)