Siegfried Meier

Well-known member

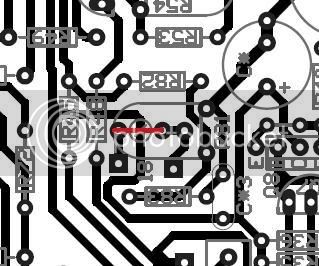

Ack, I'm a dolt. Thanks for the tip 3nity, but this is actually what was wrong. After reading this statement on Mnats site:

5k Trimmers - Optional (in place of R3, R5)

Duh, I also added in the resistors. Cut them and it's perfect now!

Thanks,

Sig

5k Trimmers - Optional (in place of R3, R5)

Duh, I also added in the resistors. Cut them and it's perfect now!

Thanks,

Sig