skal1

Well-known member

stupid me i brought the wrong wire , i got 24 awg 7 strand

cheers

skal

cheers

skal

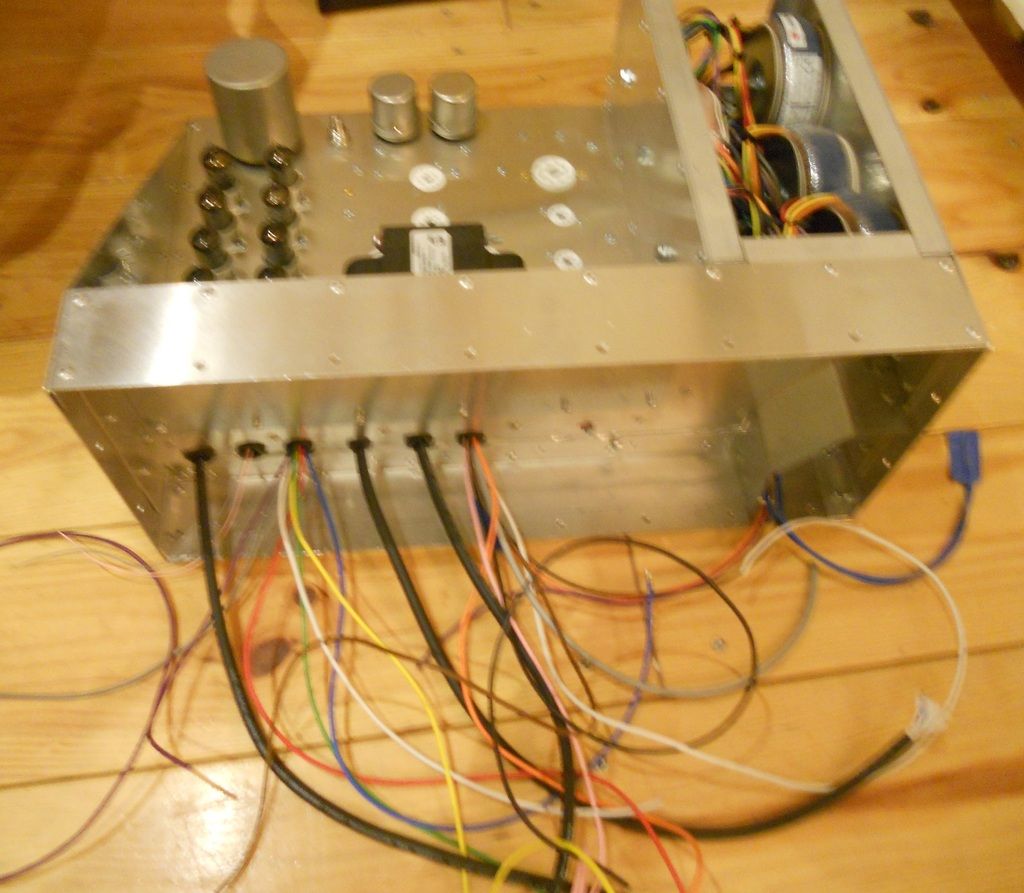

You cover the metal with masking tape, mark it out, drill holes for corner radius, jigsaw between holes just short of the line, then file to line by hand. finish off with emery paper.How does one do such clean metalwork, and rivets..

This is part no 171-7281 from Farnell /NewarkWhat is the cute / pro looking sticker you have on the back panel with black and silver rectangles, filled in with info?

DaveP said:You cover the metal with masking tape, mark it out, drill holes for corner radius, jigsaw between holes just short of the line, then file to line by hand. finish off with emery paper.

Thanks for thumbs up.

DaveP

Yes, that is something I would be totally all over.tommypiper said:.. we should start a new thread on your amazing metalwork....Really, the whole group of mechanical and electrical skills you have are enviable.

Here in France I have a shop called Leroy Merlin, it sells aluminium sheets 1.5mm thick x 500x 300mm. It also sells various sizes of aluminium angle, 15x15mm is handy. I expect you have even better shops like this in the US.How do you make such clean straight-line cuts? For example, the covers on the toroid box have very clean straight edges.

No, I'm cutting about 1 or 2 mm away from a line. The line can be scored with a scriber or just a ballpoint line as long as you can see it OK. The jigsaw blade for straight lines is longer than the one for going around circles, so it's not too hard to keep it straight, especially if you can control the speed. You can practice on scrap beforehand.So you must be cutting against a straight edge guide with the jig saw?

Enter your email address to join: