Once again, I asked you if you were familiar with commercially manufactured boards, NOT to put you down, but because some people aren't, and I have no way of assessing your level of expertise from an anonymous e-mail. Some people are surprised the PCBs are drilled, some are surprised there is even plating, because they are only used to seeing exposed copper. Usually, it is best to get those trivialities out of the way before assuming there is a special problem from a report of white pads.

I suggested the silver plating might be throwing you off, because it has happened to others (Even Jakob was a little confused by the milky white color after we we switched to silver to make the boards rhos compliant, but I asked him to try to make a joint, and he has been soldering white pads happily ever since).

I did not draw any final conclusions, and I asked for pictures. I have also stressed that I am willing to investigate further, but I am 100% sure that it is not the color of your pads that is a problem, and I stand by my statement that the pictures look fine (even thought there might still be a problem, of course!). The plating is 100% lead free chemical silver, and the silver quality used is in fact higher than you would normally get from standard PCB manufacturers. The surface settles very quickly into the white color when it is exposed to air (oxidation), but it does not hinder soldering.

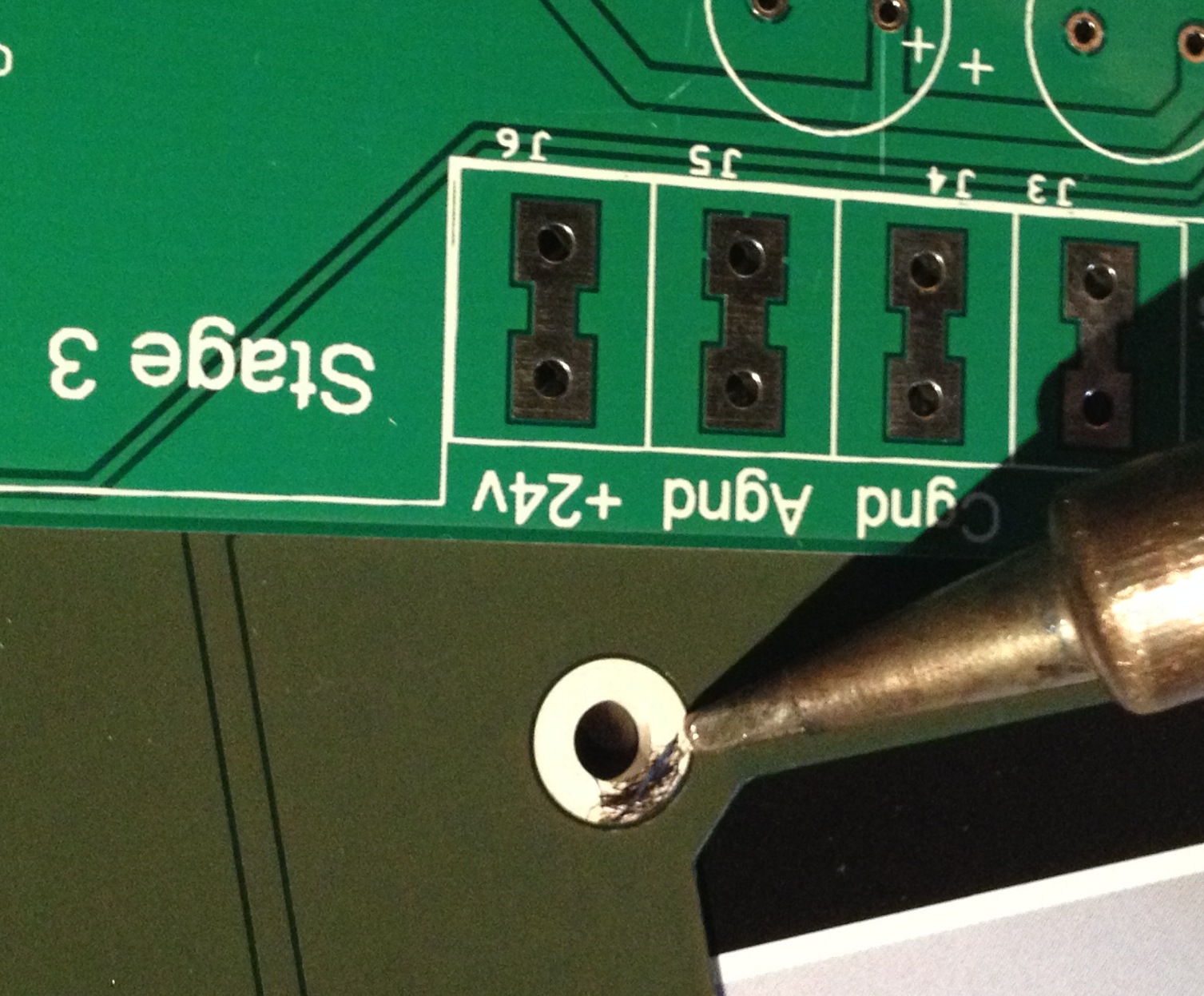

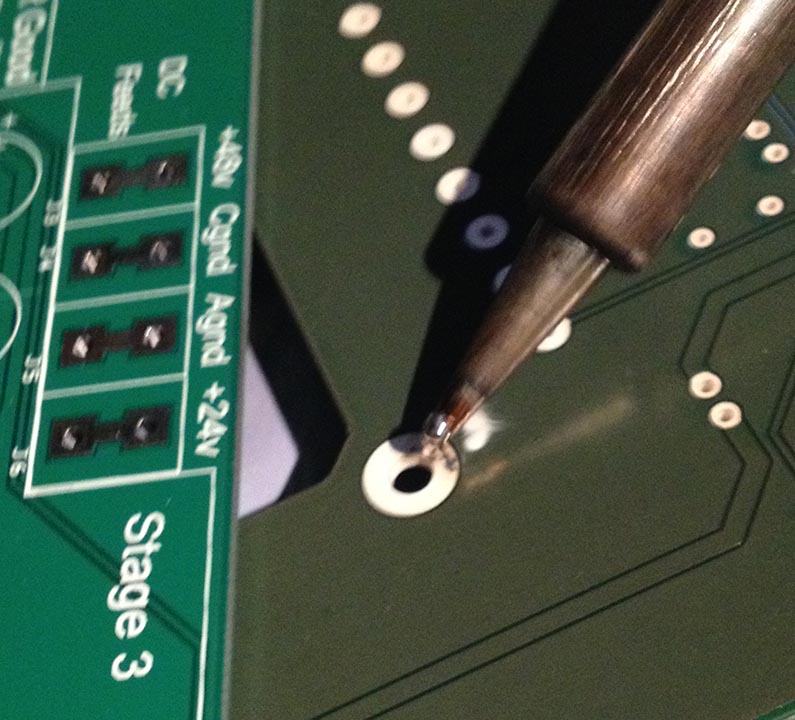

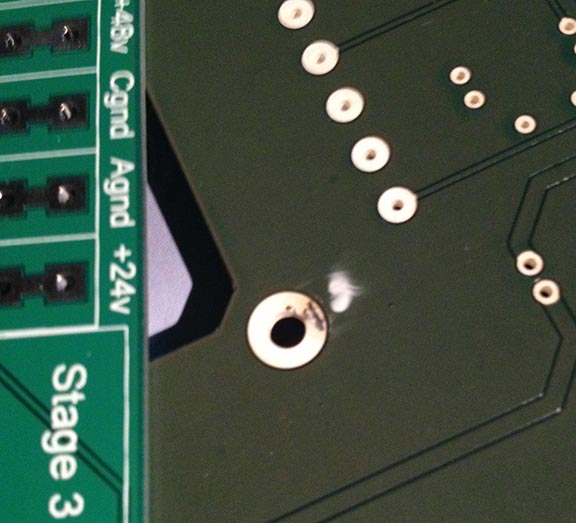

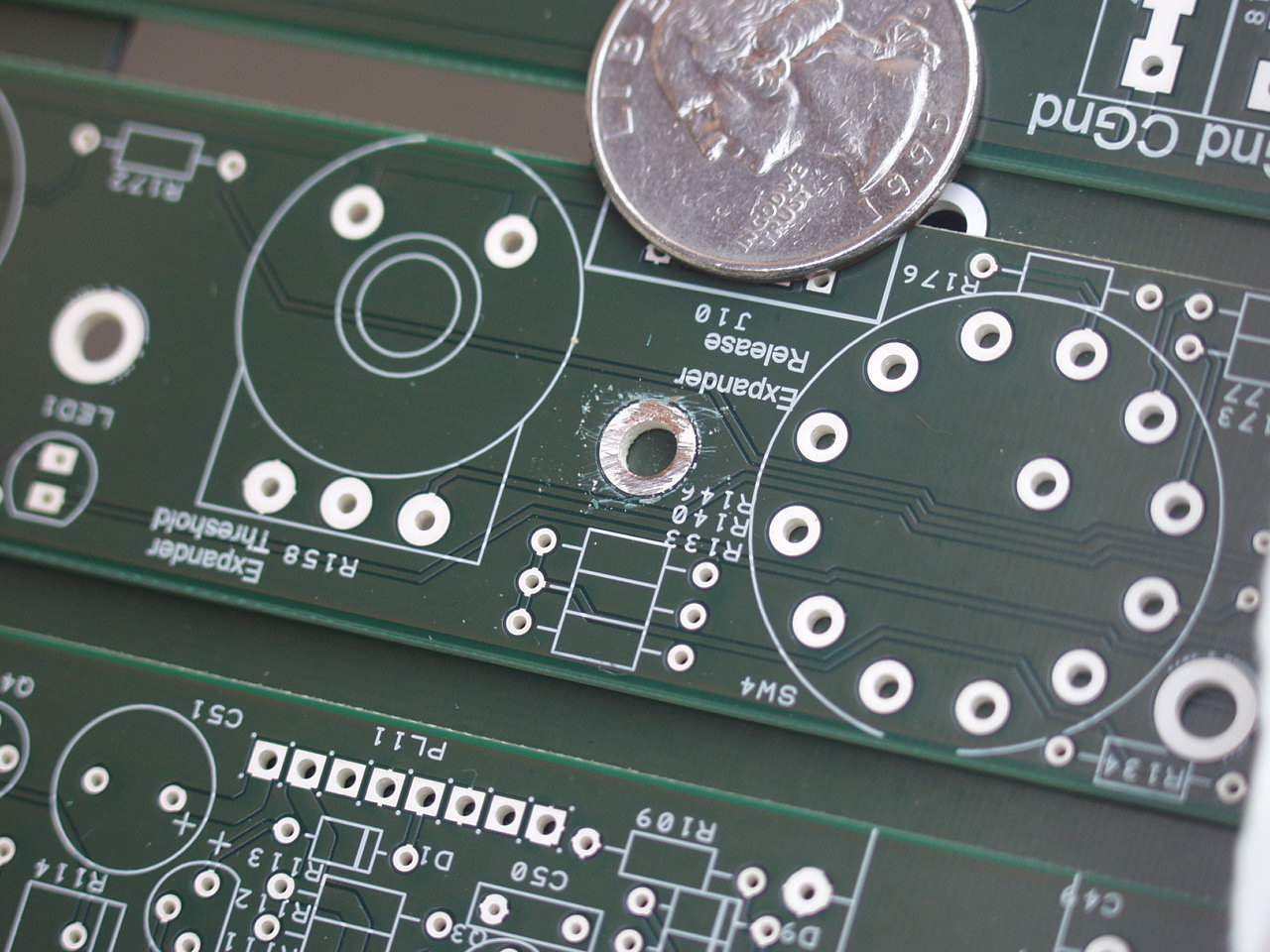

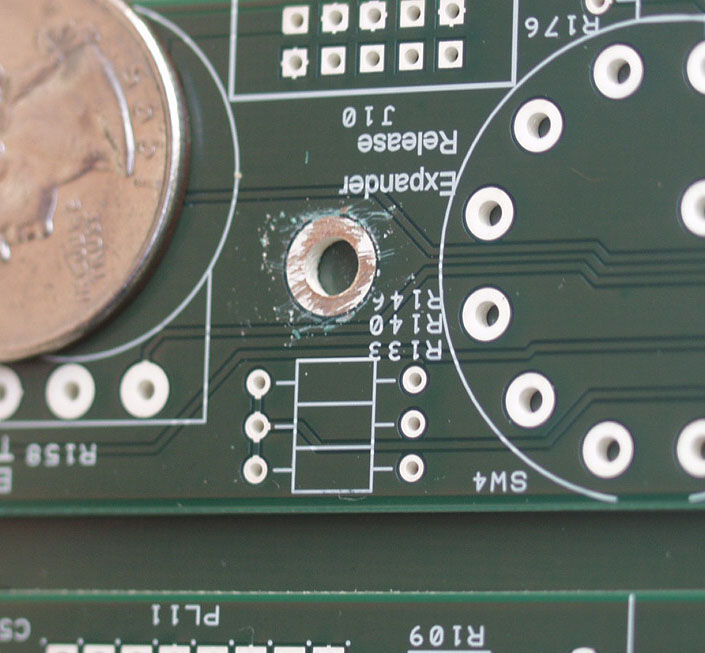

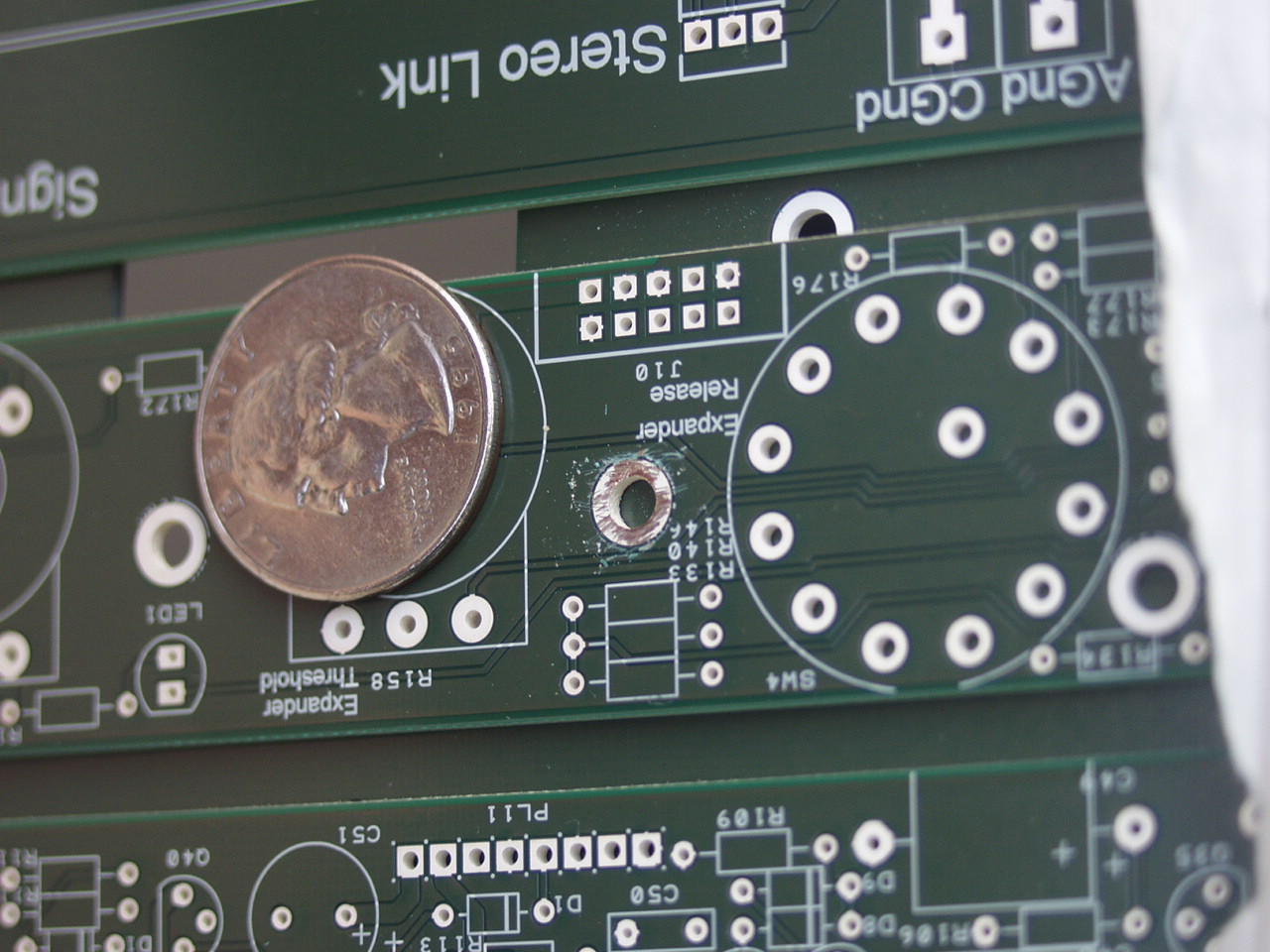

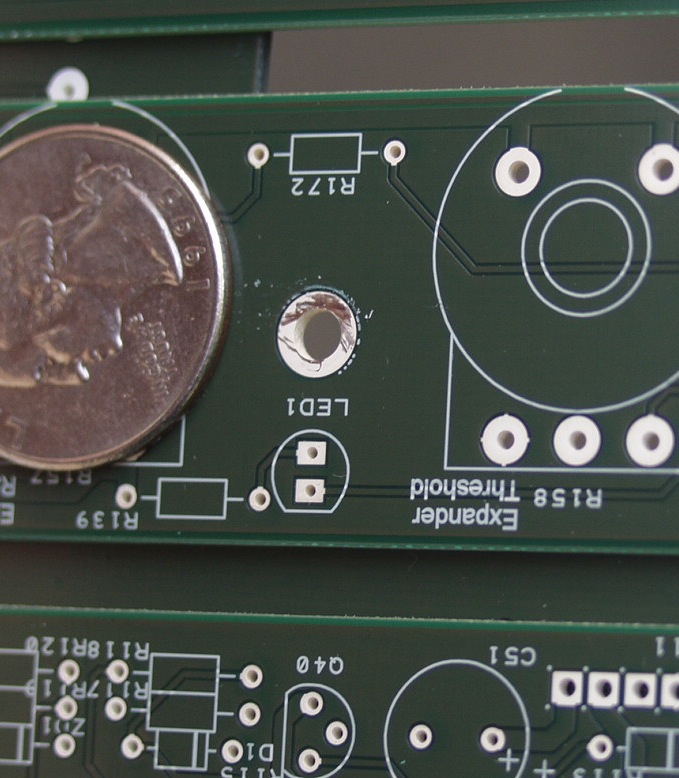

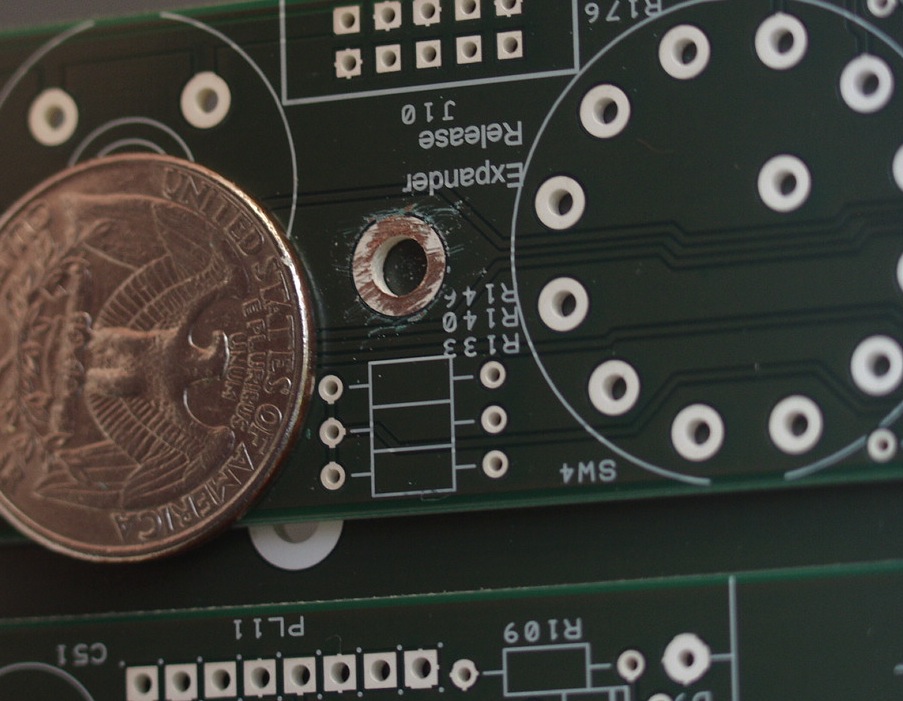

For comparison, I took a picture of the pad that you showed a burned picture of (yes, they do hold up to abuse quite well, and again - I do not see it as a problem that you report that you have to abuse the pad to burn it) - pre and post soldering. I also added a random resistor to the board.

The milky white silver pads hold solder perfectly - as per usual.

I think its safe to say that the problem does not lie in the color of your pads or a layer of paint, and I am 100% sure it is not the gerbers, so I can't agree the customer is always right if your conclusion stands. I seem to be unable to communicate with you in a way that doesn't make you think I am trying to insult your intelligence, "blame you" or belittle you, and even though it would benefit me greatly to know what the actual problem is, so I have a chance of avoiding an outlier like this in the future, I am a bit lost for ways to progress with this in a fruitful way.

I cannot simply replace your boards, because the silver plating would be the same, unless I make a special production run using lead free HAL (tin based, lead free). We also have not come to any conclusions about what the problem actually is that would make me certain you would be better off with new boards.

I am also still not sure how my e-mail response to you could make you fell like I am talking down to you.

"Hi xxxx.

Im a little confused by your questions, so try sending me a picture. Either (assumption, which is almost always a bad idea), you are not familiar with commercially manufactured PCBs, or there is something really wrong with your boards!?

The pads are silver plated, sometimes you will find other platings of tin/lead variations done by hot air leveling, but if this is what is confusing you, and you are used to exposed copper pads, I can assure you, the plating will make you very happy when you start soldering them."

I have really not meant to be unfriendly or unsupportive. I will refund your payment as soon as the Paypal dispute you opened is brought to a level where I can reply to it and access my paypal account again. I can't seem to top it off with my CC with an open dispute, and the funds are not there to close it now, so i will have to wait for a direct transfer from my bank account to transfer your refund.

I apologize for the obvious inconvenience this has caused you.

Gustav

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)