tardishead

Well-known member

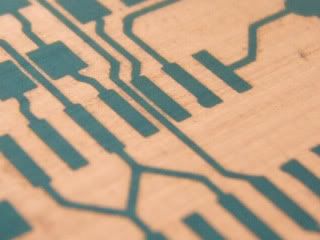

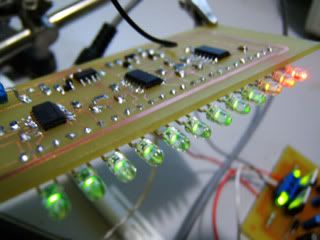

I've made alot of PCBs but I have always struggled to print transparencies with my **** inkjet printer. I just cant take it anymore.

does anyone out there have the definitive answer to printing your own artworks with a PC printer? or is it better to just go to a local print shop and get them to print with a laser printer

I have tried that aswell but most of the time my results at home are better even if I have to run it through the printer twice. and they charge ridiculous money

does anyone out there have the definitive answer to printing your own artworks with a PC printer? or is it better to just go to a local print shop and get them to print with a laser printer

I have tried that aswell but most of the time my results at home are better even if I have to run it through the printer twice. and they charge ridiculous money