sahib

Well-known member

Time for an update.

Second batch of 100 is under production. Connectors are in stock.

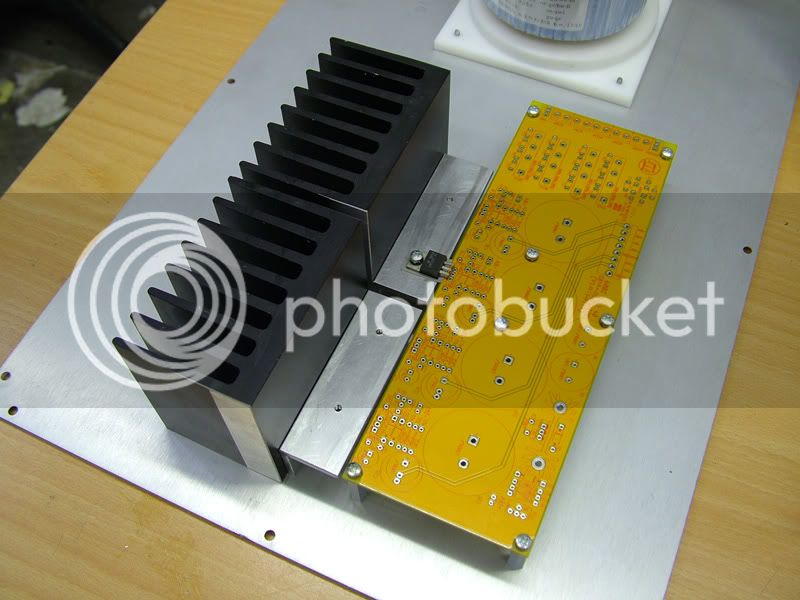

The design of the mechanics of the psu is completed and I am building the final prototype this weekend and will be testing it. It is almost there.

Stay tuned.

Second batch of 100 is under production. Connectors are in stock.

The design of the mechanics of the psu is completed and I am building the final prototype this weekend and will be testing it. It is almost there.

Stay tuned.