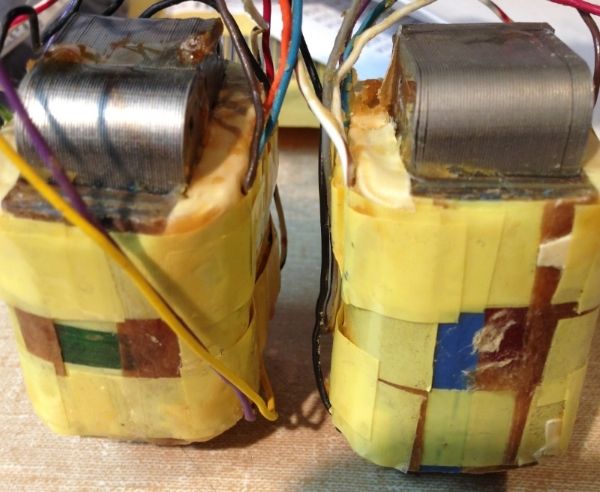

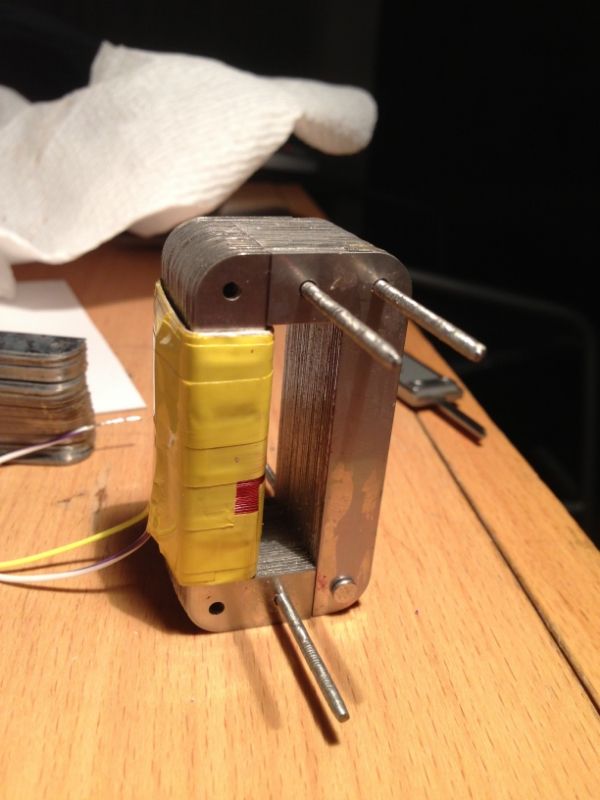

I know what this is, but thought it was interesting, and beautifully made... Anyone want to take a guess at what it is before I reveal it?

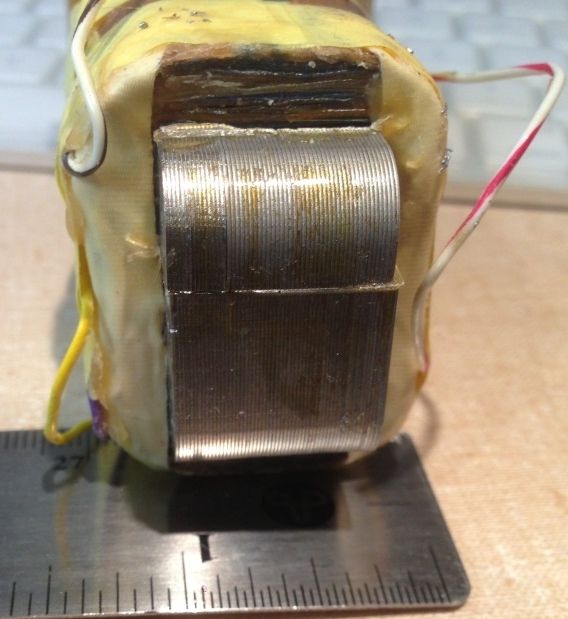

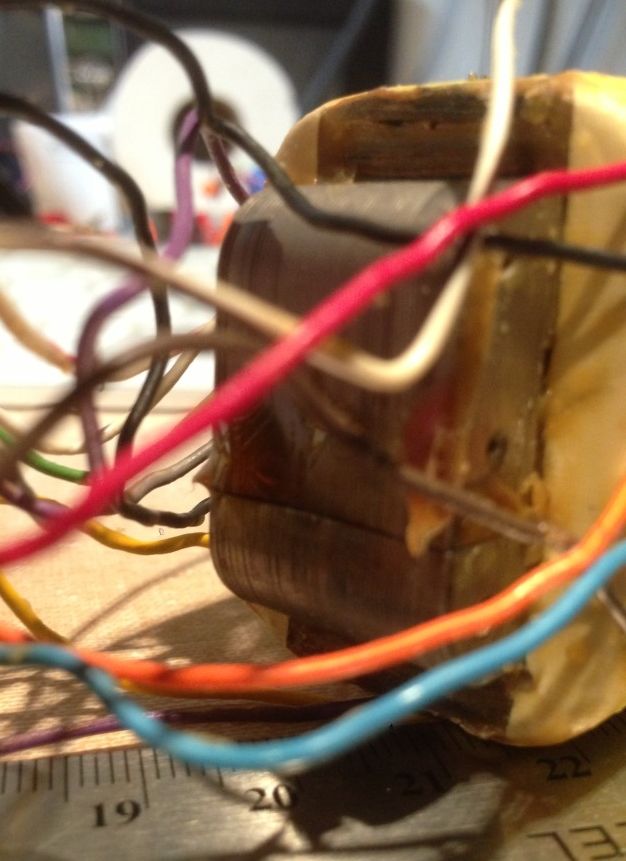

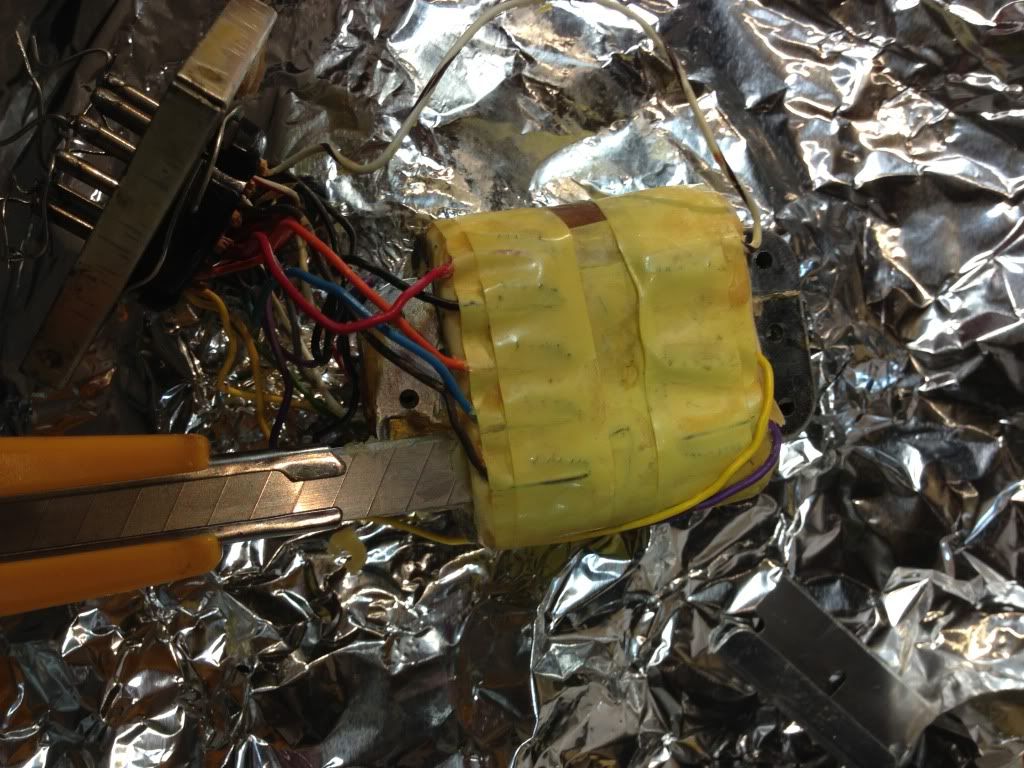

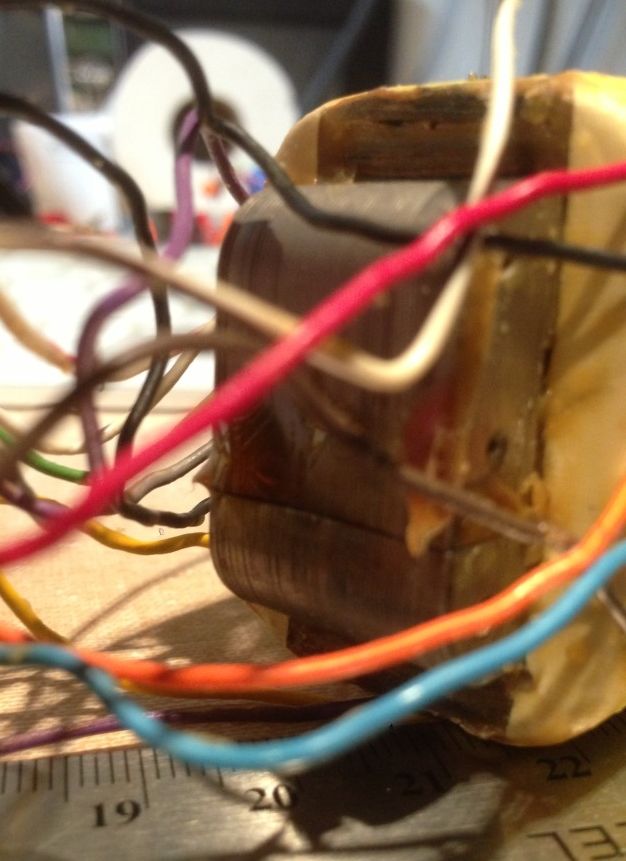

It has lots of taps. In a 3.5:1 stepdown configuration it is 2.6 H on the primary (21 ohms) and 190mH 5 ohms on the secondary. If it is nickel the inductance is pretty low, the wire seems to be sort of #34 or #32 (some of the coil is exposed) but I don't know.

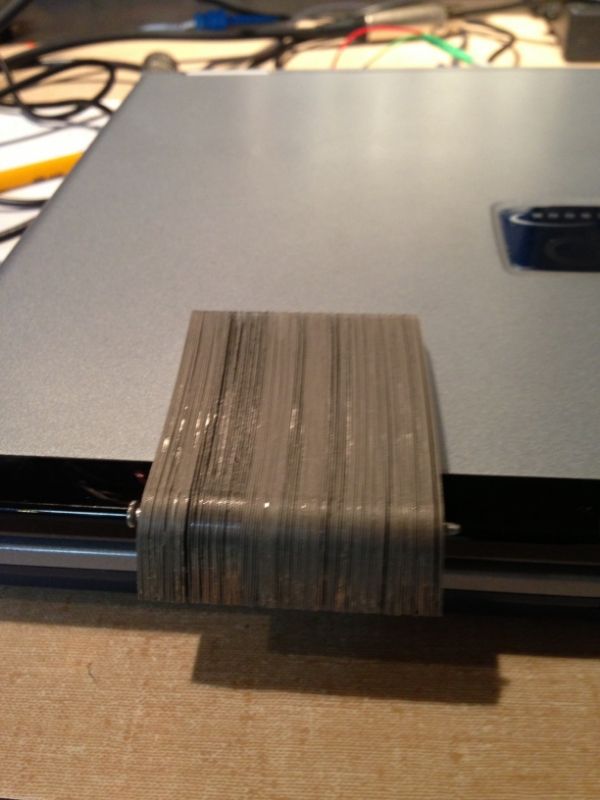

I de-potted it from wax, but it works, so I thought I would stop here.

More things I don't know, that maybe someone else does:

Even at 20hZ it takes a lot to saturate it.

Frequency response driven by low impedance is within 0.35dB of my test gear's response curve. Driven by higher impedance (3K) it gets a a little ugly at 20Hz with higher levels.

It has lots of taps. In a 3.5:1 stepdown configuration it is 2.6 H on the primary (21 ohms) and 190mH 5 ohms on the secondary. If it is nickel the inductance is pretty low, the wire seems to be sort of #34 or #32 (some of the coil is exposed) but I don't know.

I de-potted it from wax, but it works, so I thought I would stop here.

More things I don't know, that maybe someone else does:

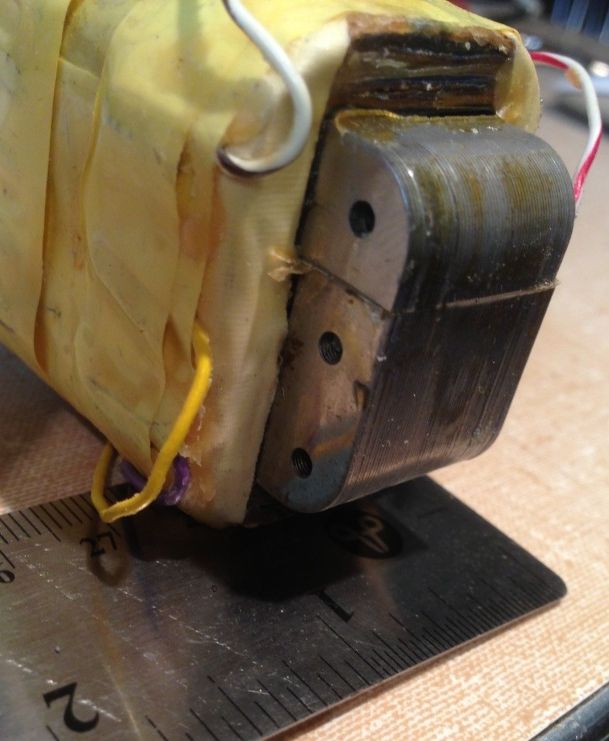

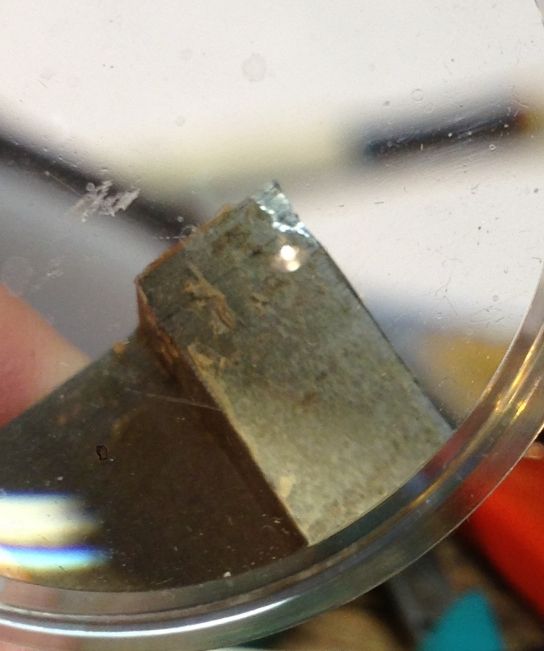

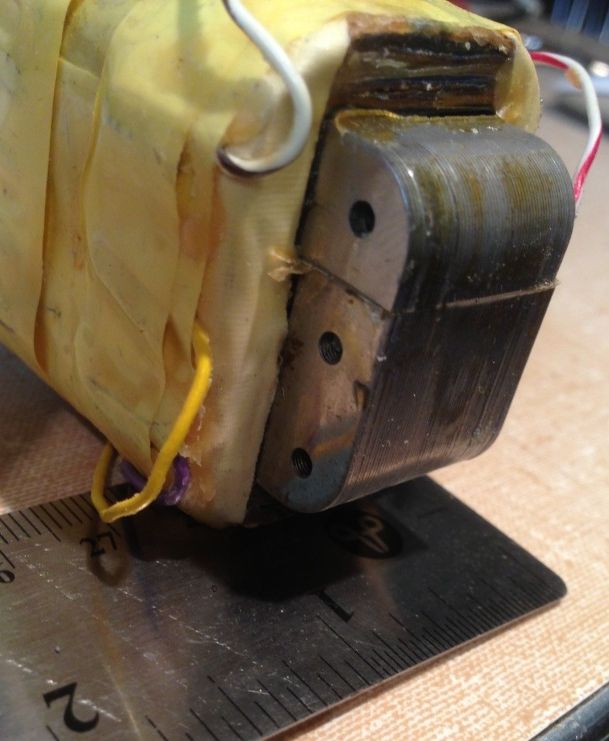

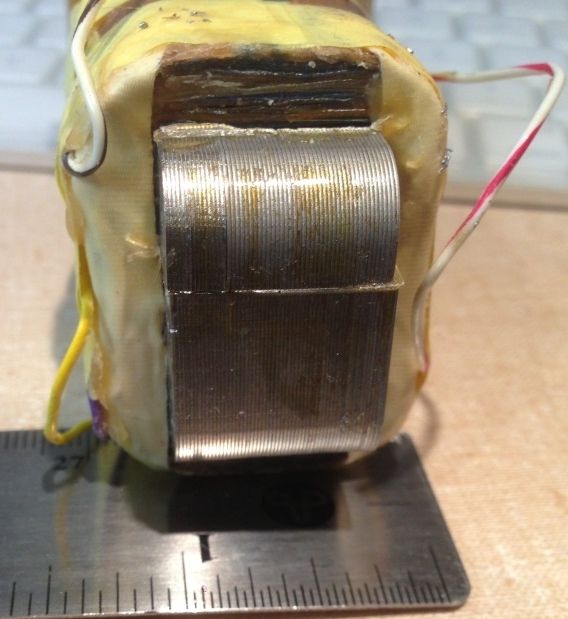

- Does the shiny surface imply that it is nickel? (it is many years old, but no rust). Maybe the low inductance is because it is gapped?

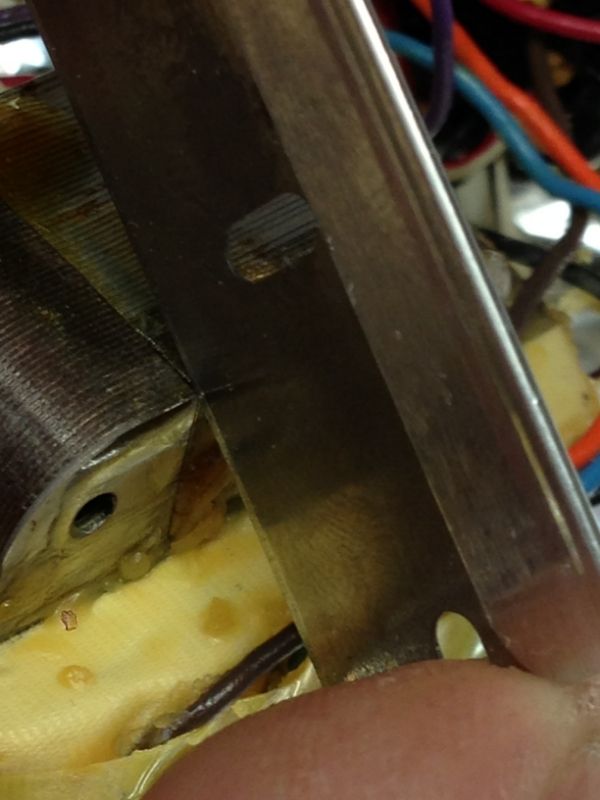

- Do the cracks at the end (which seem to have paper spacers, and seem to be glued) mean that it is gapped?

- It has lots of taps, but in a 3.5:1 stepdown configuration it is 2.6 H on the primary (21 ohms) and 190mH 5 ohms on the secondary. I assume the low inductance would indicate it was gapped too.

- Is it wound like a C core? (the laminations seem to be L's not overlapped and gapped with paper at both ends by and glued).

- Suggested uses?

Even at 20hZ it takes a lot to saturate it.

Frequency response driven by low impedance is within 0.35dB of my test gear's response curve. Driven by higher impedance (3K) it gets a a little ugly at 20Hz with higher levels.